Operation instructions, Service instructions, Performance characteristic curve – Bell & Gossett V58766 Triple Duty Valve Model 3DV User Manual

Page 2

d) When sweating the joints, first adjust the valve in the full

open position, then wrap the valve with a cool wet rag

and then direct the flame with care to avoid subjecting

the valve to excessive heat. Allow the valve to cool

before touching or operating.

e) Check the soldered connection for leaks.

2. For installing NPT connections:

Apply pipe compound conservatively to male connecting

fittings only.

After installation check all joints for leakage and retighten

where necessary.

OPERATION INSTRUCTIONS

1. Energize the zone, circuit and/or system pump(s) as

applicable.

2. Using Bell & Gossett Model RP-250B Readout Probes,

sequentially attach a Bell & Gossett differential pressure

readout kit to the readout valves on each 3DV.

WARNING: Use of improper procedures to sweat

valve model with union connection into system can

damage valve. Before installing sweat union connection to

valve, remove the union nut and O-ring from the valve

body, then union tailpiece with union nut must be sweated

(soldered) into place. Failure to follow this instruction could

result in property damage and/or moderate personal injury.

© COPYRIGHT 2006

PRINTED IN U.S.A. 7-06

Bell & Gossett

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

http://www.bellgossett.com

3. Read the differential pressure across the orifice of the 3DV.

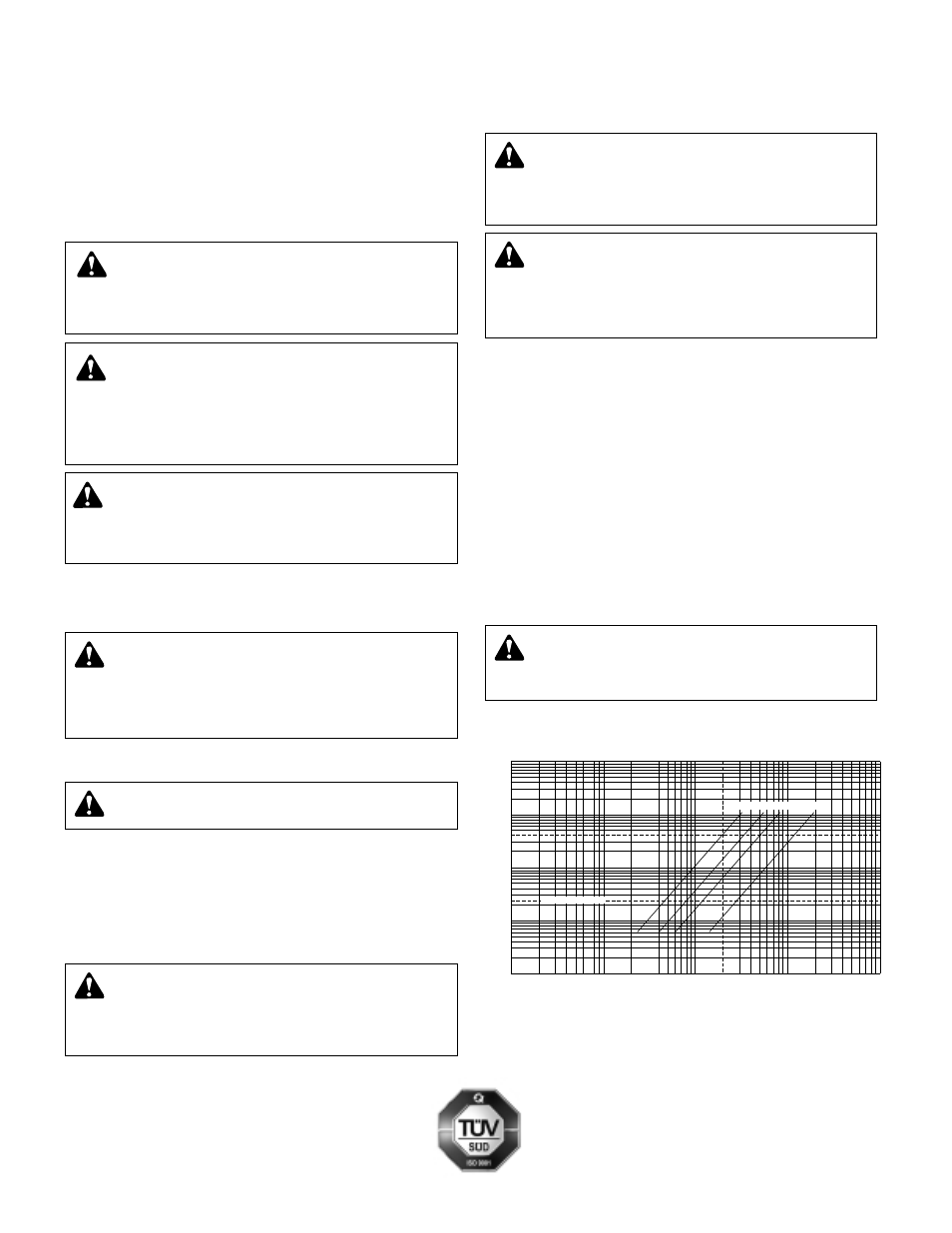

4. Use the differential pressure chart (shown below) to read

actual GPM.

Example: The 3DV model 1" NPTF. If the differential pres-

sure across the orifice reads at 40' W.C. the flow rate is

20 GPM.

HOW TO USE THE MEMORY STOP FEATURE

1. Make the final degree of closure setting.

2. Loosen the handle nut and rotate memory stop until it

locks against the body.

3. Tighten the handle nut.

SERVICE INSTRUCTIONS

Periodically inspect the 3DV for signs of leakage or corrosion.

PERFORMANCE CHARACTERISTIC CURVE

(NOTE: Flowmeter Cv for Balancing)

CAUTION: Heat Associated with the use of silver

solder may damage a Venturi/Ball valve and void the

product warranty. Do not use silver solder. Failure to follow

these instructions could result in property damage and/or

moderate personal injury

CAUTION: The use of Teflon

®

* impregnated pipe

compound and Teflon tape on pipe threads provides

lubricity. Care should be taken to prevent overtightening

which may damage the valve body. Failure to follow these

instructions can result in moderate personal injury and/or

property damage.

CAUTION: Make sure that all the connecting pipework

is water tight.

WARNING: Hot water leakage can occur from read-

out valves during probe insertion and during hookup

of readout kit. Follow the instruction manuals supplied with

readout probes and readout kits for safe use. Failure to

follow these instructions could result in serious personal

injury or death and property damage.

CAUTION: When making the water connections, make

sure that the pipework connecting the 3DV is not

mechanically over-stressed. Over time this could cause

breakages, with consequent water losses which, in turn,

could cause harm to property and/or people.

CAUTION: Water temperatures higher than 100°F

(38°C) can be dangerous. During the installation,

commissioning and maintenance of the 3DV, take the

necessary precautions to ensure that such temperatures

do not endanger people.

WARNING: Corrosion or leakage is indication that

the 3DV must be replaced. Failure to follow these

instructions could result in serious personal injury or death

and property damage.

CAUTION: Excessive use of solder in a vertical instal-

lation may result in damage to the valve seat and ball.

Do not use excessive flux. Failure to follow these instruc-

tions could result in property damage and/or moderate

personal injury.

*Teflon is a registered trademark of E.I. DuPont de Nemours and Company.

1000

100

10

40

1

0

0

0

0

1

0

0

1

0

2

0

1

1

0

SS

ER

P

D

ER

U

(

PO

R

W F

O

TE

EF

)R

ET

A

CAPACITY (GPM)

Cv Reference Line

1"

2"

1-1/4" 1-1/2"