Discharge piping, Rotation, Operation – Bell & Gossett P81845B Series 3530 Centrifugal Pumps User Manual

Page 4: Maintenance, Disassembly

3.2 Suction pipe must be at least as large as the suction

connection of the pump. Smaller size will degrade

performance.

3.3 If larger pipe is required, an eccentric pipe reducer

(with straight side up) must be installed at the pump.

3.4 Installation with pump below source of supply:

3.4.1 Install full flow isolation valve in piping for inspec-

tion and maintenance.

3.5 Installation with pump above source of supply:

3.5.1 Avoid air pockets. No part of piping should be

higher than pump suction connection. Slope pip-

ing upward from liquid source.

3.5.2 All joints must be airtight.

3.5.3 Foot valve to be used only if necessary for prim-

ing, or to hold prime on intermittent service.

3.5.4 Suction strainer open area must be at least triple

the pipe area.

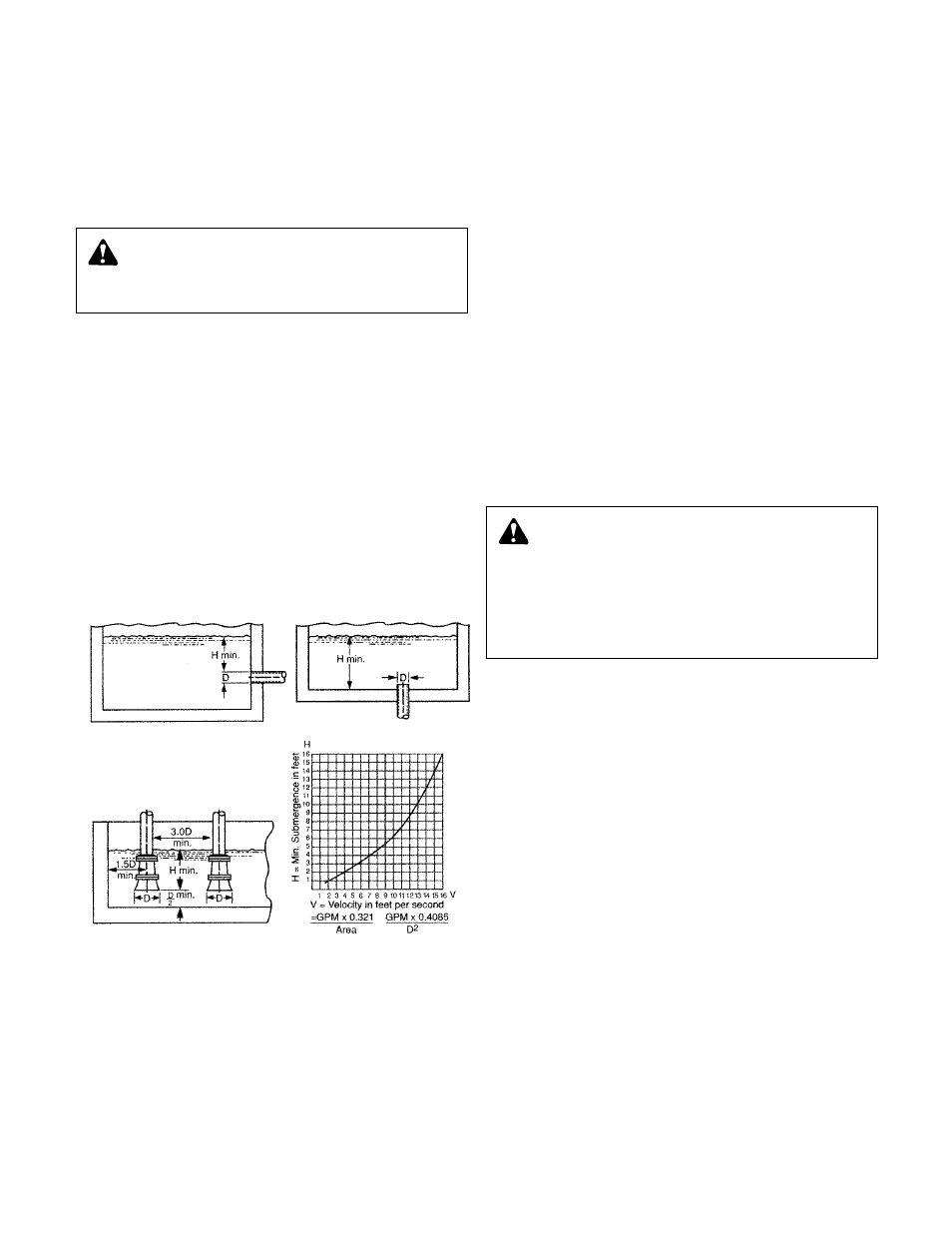

3.6 Size of inlet from liquid source, and minimum submer-

gence over inlet, must be sufficient to prevent air

entering pump through vortexing. See Figs. 2-5.

3.7 User 3-4 wraps of Teflon tape to seal threaded

connections.

4. DISCHARGE PIPING

4.1 Arrangement must include a check valve located

between a gate valve and the pump. The gate valve is

for regulation of capacity, or for inspection of the pump

or check valve.

4.2 If an increaser is required, place between check valve

and pump.

4.3 Use 3-4 wraps of Teflon tape to seal threaded

connections.

5. ROTATION

5.1 Correct rotation is right-hand (clockwise when viewed

from the motor end). Switch power on and off quickly.

Observe shaft rotation. To change rotation:

5.1.1 Single-phase motor: Non-reversible.

5.1.2 Three-phase motor: Interchange any two power

supply leads.

6. OPERATION

6.1 Before starting, pump must be primed (free of air and

suction pipe full of liquid) and discharge valve partially

open.

6.2 Make complete check after unit is run under operating

conditions and temperature has stabilized. Check for

expansion of piping.

7. MAINTENANCE

7.1 Close-Coupled Unit. Ball bearings are located in and

art part of the motor. They are permanently lubricated.

No greasing required.

8. DISASSEMBLY

Complete disassembly of the unit will be described.

Proceed only as far as required to perform the mainte-

nance work needed.

8.1 Turn off power.

8.2 Drain system. Flush if necessary.

8.3 Remove motor hold-down bolts.

8.4 Disassembly of Liquid End:

8.4.1 Remove casing bolts (370).

8.4.2 Remove back pull-out assembly from casing

(100).

4

CAUTION: Do not use suction isolation valve to

throttle pump.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

CAUTION: Pumped liquid provides lubrication. If

pump is run dry, rotating parts will seize and mechani-

cal seal will be damaged. Do not operate at or near zero

flow. Energy imparted to the liquid is converted into heat.

Liquid may flash to vapor. Rotating parts require liquid to

prevent scoring or seizing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

Figure 2

Figure 3

Figure 4

Figure 5