Floa t switch adjustment – Bell & Gossett DN0129D Series CMU User Manual

Page 3

3

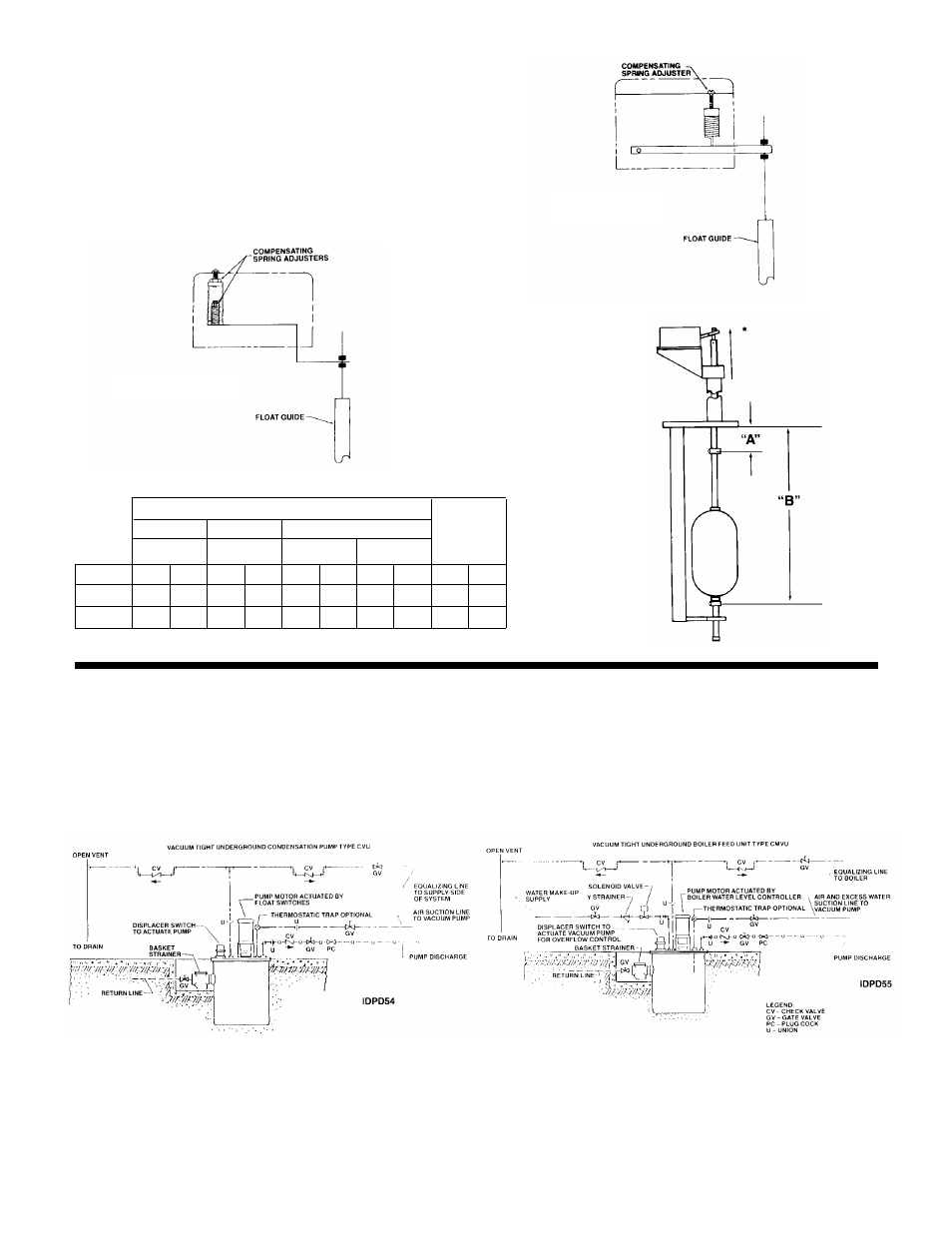

FLOA

T SWITCH ADJUSTMENT

The float positions ar

e factory set. These positions should be

reset as necessary. Minor deviation is permissible to meet local

requirements. The settings must avoid “short cycling” of the

pumps.

The float switch and mechanical alternator each have an inter-

nal compensating spring to balance the weight of the float

guide rod. These springs are to have just enough tension or

compression on the float switch to counterbalance the guide

rod (but not the float).

PIPING DIAGRAMS V

ACUUM TIGHT

UNDERGROUND CONDENSATE &

BOILER FEED UNITS

T

ype CVU units are designed for use as a mechanical lift in a

vacuum heating system. They are also used to return conden-

sate under vacuum to a boiler feed tank. They have vacuum

tight displacer switch(es) for pump control.

Type CMVU units have water make-up valve and are actuated

by boiler controller. They are designed for use in a vacuum sys-

tem to discharge condensate directly to the boiler.

It is necessary to pipe the vent line to atmosphere using full

vent port size piping with check valves installed as shown on

diagrams. It is also recommended that the vent line be

“dripped” to drain to prevent an accumulation of condensate in

the vent pipe.

*

MAKE SETTINGS

WITH ARM AT

HIGHEST POSITION

MECHANICAL

ALTERNATOR

FLOAT SWITCH

2DFS01

PIPING DIAGRAM FOR UNDERGROUND

CONDENSATE UNIT USED

IN A VACUUM SYSTEM

PIPING DIAGRAM FOR UNDERGROUND

BOILER FEED UNIT USED

IN A VACUUM SYSTEM

FLOAT SETTING CHART

Condensate Unit

Single

Duplex

Duplex 2 Float Switch

Boiler

Primary

Stand-By

Feed

Unit

(Mech. Alt.)

Float Switch

Float Switch

Unit

Depth

“A”

“B”

“A”

“B”

“A”

“B”

“A”

“B”

“A”

“B”

36"

11"

22"

8

1

/

2

"

21" 12

1

/

2

" 22"

11"

22"

14"

22"

48"

11"

34"

8

1

/

2

"

33" 12

1

/

2

" 34"

11"

34"

26"

34"