Xylem IM126R02 E-Z Prime Jet Pump Shallow Well Jet Pump User Manual

Page 8

8

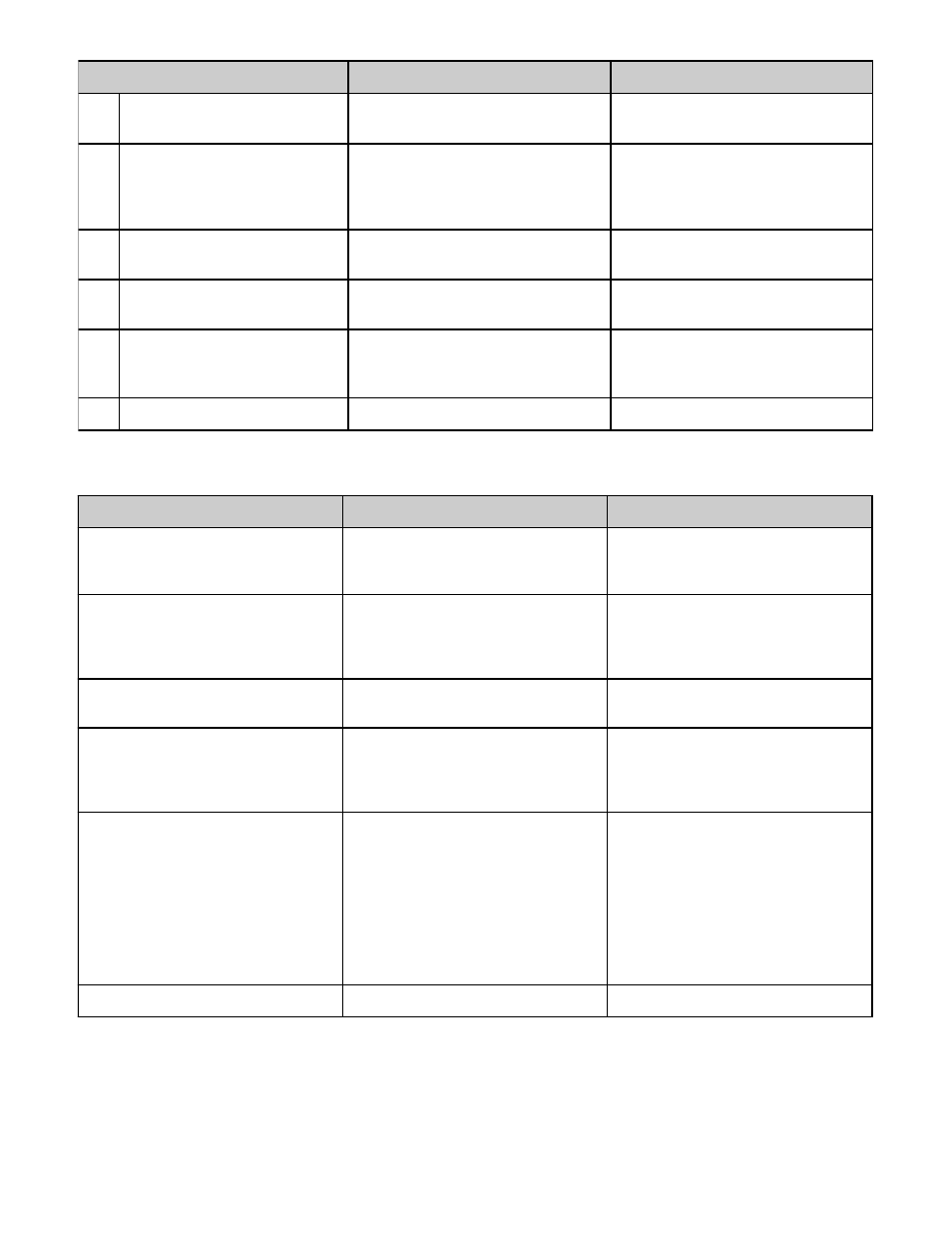

Cause of Trouble

How to Check

How to Correct

1. Leak in pressure tank.

Apply soapy water to entire surface

above water line. If bubbles appear,

air is leaking from tank.

Repair leaks or replace tank.

2. Defective air volume control.

This will lead to a waterlogged tank.

Make sure control is operating

properly. If not, remove and examine

for plugging.

Clean or replace defective control.

3. Faulty pressure switch.

Check switch setting. Examine switch

contact for dirt or excessive wear.

Adjust switch settings. Clean contact

with emery cloth if dirty.

4. Leak on discharge side of

system.

Make sure all fixtures in plumbing

system are shut off. Then check all

units (expecially ballcocks) for leaks.

Listen for noise of water running.

Repair leaks as necessary.

5. Leak on suction side of system.

On shallow well units, install pressure

gauge on suction side.

Close the discharge line valve. Then,

using a bicycle pump or air

compressor, apply about 30 psi

pressure to the sytem. If the system

will not hold this pressure when the

compressor is shut off, there is a leak

on the suction side.

Make sure above ground connections

are tight, then repeat test. If

necessary, pull piping and repair leak.

6. Leak in foot valve.

Pull piping and examine foot valve.

Repair or replace defective valve.

Cause of Trouble

How to Check

How to Correct

1. Wrong pressure switch setting

or setting "drift".

Lower switch setting. If pump shuts

off, this was the trouble.

Adjust switch to preopen setting.

2. Defective pressure switch.

Arcing may have caused switch

contact to "weld" together in closed

position. Examine points and other

parts of switch for defects.

Replace switch if defective.

3. Tubing to pressure switch

plugged.

Remove tubing and blow through it. Clean or replace if plugged.

4. Loss of prime.

When no water is delivered, check

prime of pump and well piping.

Re-prime if necessary.

5. Low well level.

Check well depth against

performance to make sure pump

and injector are properly sized.

If undersized, replace pump or

ejector.

6. Plugged injector or ejector.

Remove and inspect.

Clean and reinstall if dirty.

C. PUMP WILL NOT SHUT OFF

D. PUMP STARTS AND STOPS TOO OFTEN