Xylem IM126R02 E-Z Prime Jet Pump Shallow Well Jet Pump User Manual

Page 5

5

Installation Tip

The pressure switch supplied with 1/2 hp and 3/4 hp

Jet Pump is preset to 20-40 psi (pump turns on when

system pressure drops to 20 psi — pump turns off when

system pressure reaches 40 psi). The 1 hp and 1-1/2 hp

Jet Pumps are preset at 30-50 psi. If adjustments are

necessary to fit your system needs, follow the adjustment

instructions on the inside cover of the pressure switch.

If you are using a precharged pressure tank with your

system, be sure that the empty tank pressure is 1 psi lower

than the cut-in pressure setting of your pressure switch

(see Section 4 in this manual).

Section 3

Maintenance

Lubrication

1. The pump requires no lubrication.

2. For the electric motor, refer to instructions provided

by the motor manufacturer.

Seal Removal

1. Disconnect electrical service to the pump.

2. Relieve system pressure by opening a faucet or

drain valve until water stops flowing.

3. Disconnect pressure switch tubing at the barbed

fitting on the pump case. If tubing does not slide

off barbed fitting easily, cut it as close to the fitting

as possible.

4. Remove the four cap screws which hold down the

pump seal plate and motor to the pump case. Pip-

ing need not be disturbed.

5. Remove the pumping assembly, as one piece, (mo-

tor, seal plate, diffuser, and impeller) by carefully

prying them apart from the pump case. Exercise

care so as not to damage the impeller.

6. Remove the diffuser from the seal plate, exposing

the impeller.

7. Insert a regular slotted screwdriver into the slot in

the motor shaft.

8. While holding the motor shaft with the screwdriver,

unscrew the impeller by turning counter clockwise.

9. Slide rotating part of seal assembly from shaft (as

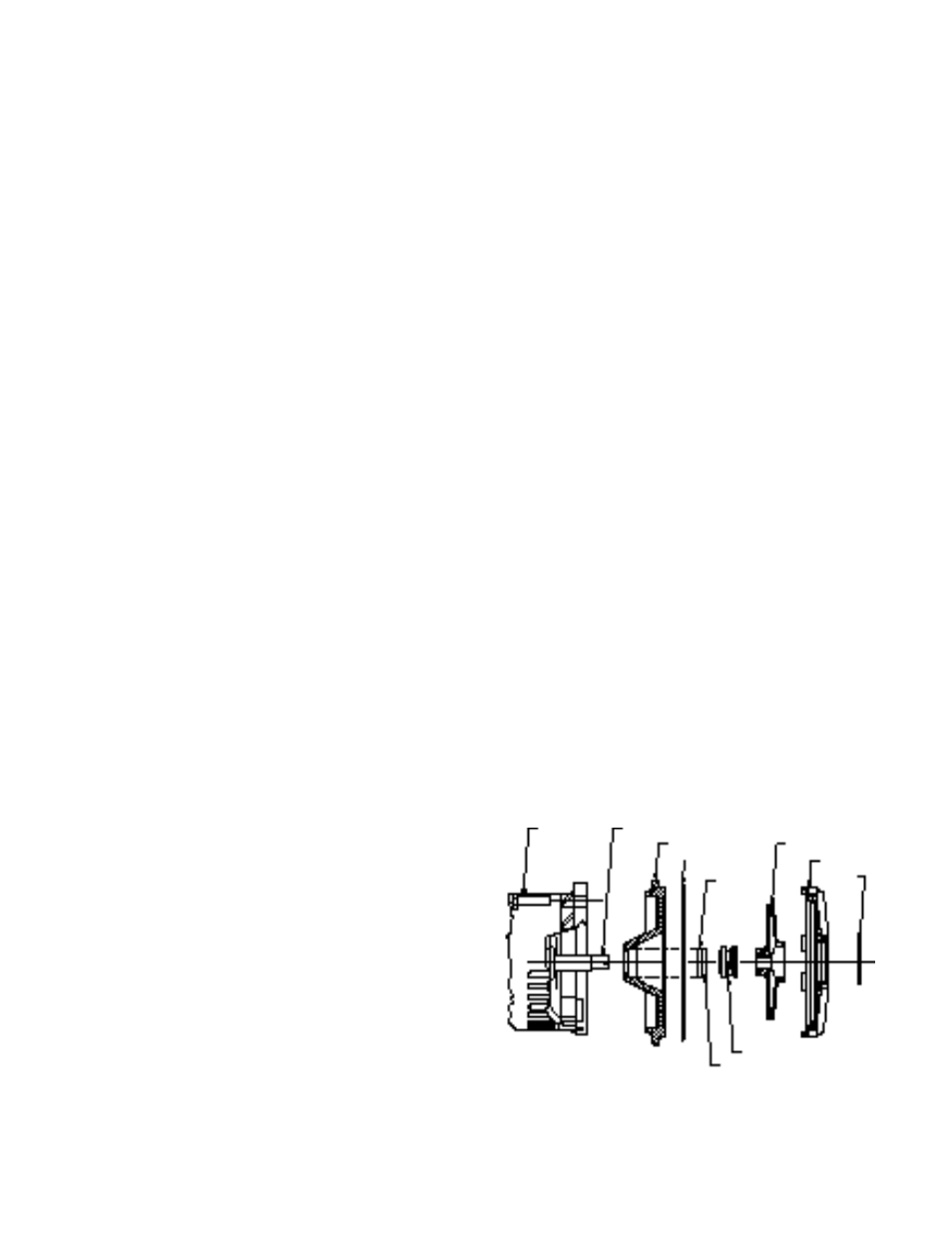

shown in Figure 3. Separate seal plate from motor.

10. Remove stationary part of seal assembly (including

rubber seal boot) from seal plate.

New Seal Installation

1. Clean polished surface of stationary seal with a

clean cloth.

2. Wet the outer edge of the rubber seal boot with a

soap solution.

3. Insert rubber seal boot and ceramic seal (polished

side exposed) into seal plate. Make a cardboard

washer to cover the ceramic seal surface to be

used while pressing seal into position. Cardboard

washer is used to avoid scratching ceramic surface.

Discard cardboard washer after ceramic seal instal-

lation (see Figure 3).

4. Reposition seal plate onto motor and slide rotating

seal assembly onto motor shaft with carbon sealing

face first until rubber end ring slides over shaft

shoulder.

5. Screw impeller clockwise onto motor shaft using

screwdriver in shaft end slot to hold the shaft.

6. Reattach diffuser to seal plate and carefully repo-

sition the pumping assembly to the pump case.

Attach with the four cap screws through motor

bracket to case.

7. Connect the pressure tubing by pressing on to

barb fitting on pump case until tubing shoulders

against stop edge of fitting. If tubing was cut off,

carefully remove excess tubing from barb fitting

with a knife, taking care not to scratch the fitting.

Motor Removal

1. Follow steps 1-10 of “Seal Removal” in this section.

Motor Replacement

1. Follow steps 1-7 of “New Seal Installation” in this

section.

Figure 3: Seal assembly.

CASE

BOLT

MOTOR SHAFT

SEAL PLATE

O-RING

SEAL

BOOT

IMPELLER

DIFFUSER

O-RING

CERAMIC SEAL

ROTATING SEAL