Xylem 8200 Series Base Mounted Centrifugal Fire Pumps AC2675 REV.C User Manual

Page 12

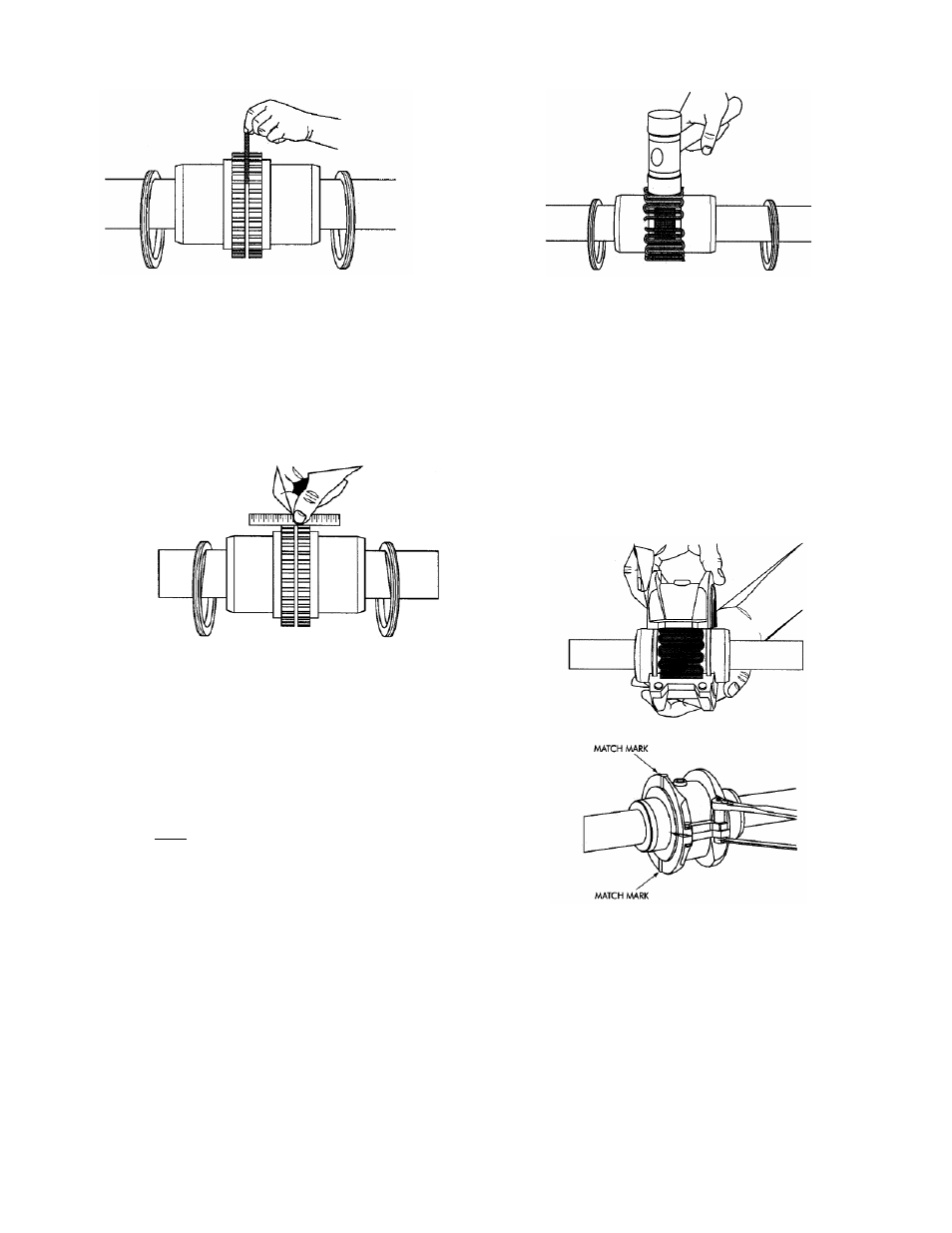

FIGURE 7C – USING SPACER BAR

9. Align so that a straight edge rests within

the limits shown in Figure 7D on both

hubs as shown below and also at 90°

intervals without rotating the coupling.

Check with feelers. The clearance must

not exceed the PARALLEL OFFSET

installation limits specified in Figure 7H.

FIGURE 7D – USING STRAIGHT EDGE

10. If adjustment is needed, loosen the motor

bolts and add (or remove) an equal

amount of shims under each motor foot to

align the height. To correct side

misalignment, strike the side of the motor

foot with a mallet.

11. Tighten the motor bolts and check again.

If a correction is made, re-check alignment

in all directions. Repeat this process until

the desired result is obtained.

12. Pack gap and grooves with coupling

vendor supplied grease before inserting

grid. When grids are furnished in two or

more segments, install them so that all cut

ends extend in the same direction as

shown below. This will ensure correct grid

contact with non-rotating pin in cover

halves.

13. Spread the grid slightly to pass over the

coupling teeth and seat with a soft mallet.

FIGURE 7E – SEATING THE GRID

14. Pack the spaces between and around the

grid with as much as coupling vendor

supplied grease as possible and wipe off

the excess until flush with the top of the

grid.

15. Position seals on hubs to line-up with

grooves in cover. Position gaskets on

flange of lower cover half and assemble

covers so that the match marks are on the

same side.

FIGURE 7F – COVER INSTALLATION

16. If the shafts are not horizontal, or coupling

is to be used vertically, assemble cover

halves with the lug and match mark UP or

on the high side. Push gaskets in until

they stop against the seals and secure

cover halves with fasteners, tightening to

torque specified in Figure 7H. Ensure

gaskets stay in position during fastener

tightening.

12