Xylem 8200 Series Base Mounted Centrifugal Fire Pumps AC2675 REV.C User Manual

Page 11

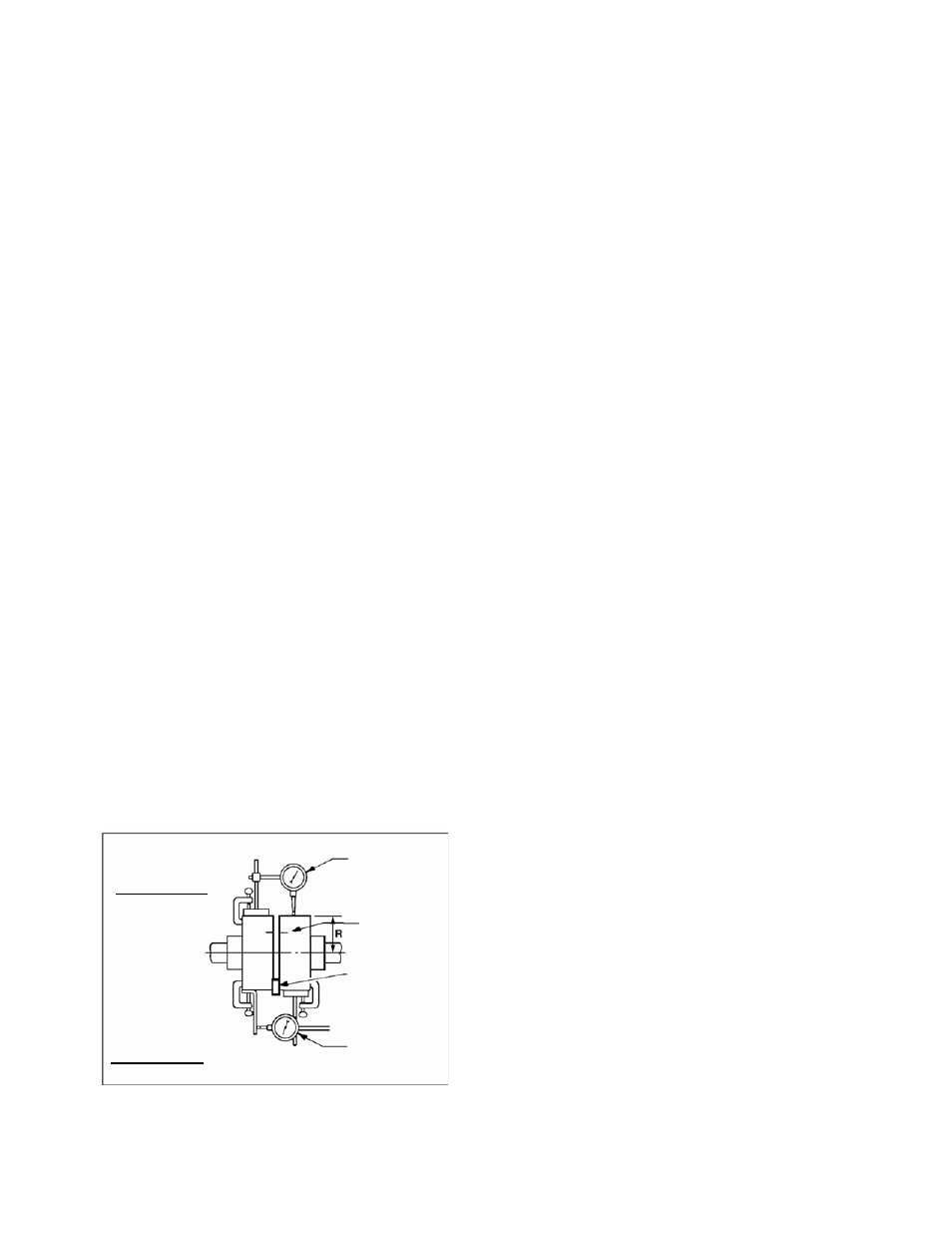

Method 2 – For Orange Hytrel Insert, 3500

RPM Operation, or All Other Coupler

Types Except as Noted Below

(See Figure 7B)

a. Make sure each hub is secured to its

respective shaft and that all connecting

and/or spacing elements are removed at

this time.

b. The gap between the coupling hubs is set

by the manufacturer before the units are

shipped. However, this dimension should

be checked. (Refer to the coupling

manufacturer’s specifications supplied

with the unit.)

c. Scribe index lines on coupling halves as

shown in Figure 7B.

d. Mount dial indicator on one hub as shown

for parallel alignment. Set dial to zero.

e. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

f. Mount dial indicator on one hub as shown

for angular alignment. Set dial to zero.

g. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

h. Assemble coupling. Tighten all bolts and

set screw(s). It may be necessary to

repeat steps c through f for a final check.

i. For single element couplings, a

satisfactory parallel misalignment is

.004"T.I.R., while a satisfactory angular

misalignment is .004"T.I.R. per inch of

radius R (See Figure 7B).

FIGURE 7B – CHECKING ALIGNMENT

(METHOD 2)

Grid Couplings

NOTE: The following procedure is intended

for mounting and alignment of Rexnord

Industries, LLC. and Clarke Fire Protection

Products, Inc., Tapered Grid Couplings.

Adequate lubrication is essential for

satisfactory operation. Grease supplied by

the coupling manufacturer is highly

recommended. Other greases to be used

should be approved by the coupling

manufacturer.

Alignment is shown using a spacer bar and

straight edge. Rexnord Industries, LLC. and

Clarke Fire Protection Products, Inc. state

this practice has been proven for many

industrial applications. Superior alignment

can be achieved through the use of dial

indicators as shown above.

1. Clean all metal parts using non-flammable

solvent.

2. Lightly coat seals with coupling vendor

supplied grease and place on shafts

before mounting shaft hubs.

3. Install keys and mount hubs with flange

faces flush with shaft ends or as otherwise

specified.

4. Reposition hubs on shafts as required to

achieve the required hub gap shown in

Figure 7H or otherwise specified. The

length of engagement on each shaft

should be roughly equal to the shaft

diameter.

5. Tighten

setscrews.

6. Bring the pump and motor halves of the

coupler into approximate height alignment,

by placing equal amounts of shims under

all the motor feet.

7. Tighten the motor bolts.

8. Use a spacer bar equal in thickness to the

gap specified in Figure 7C. Insert bar, as

shown below, to same depth at 90°

intervals and measure clearance between

bar and hub face with feeler gauges. The

difference in minimum and maximum

measurements must not exceed the

angular installation limits shown in Figure

7H.

DIAL

INDICATOR

PARALLEL

ALIGNMENT

INDEX LINE

RESILIENT

SEPARATOR

ANGULAR

ALIGNMENT

DIAL

INDICATOR

11