Pressure & flow – Analytical Industries GPR-1100 ATEX Portable Trace PPM Oxygen Analyzer User Manual

Page 8

8

Pressure & Flow

All electrochemical oxygen sensors respond to partial pressure changes in oxygen. The inlet pressure must always

be higher than the pressure at the outlet vent which is normally at atmospheric pressure.

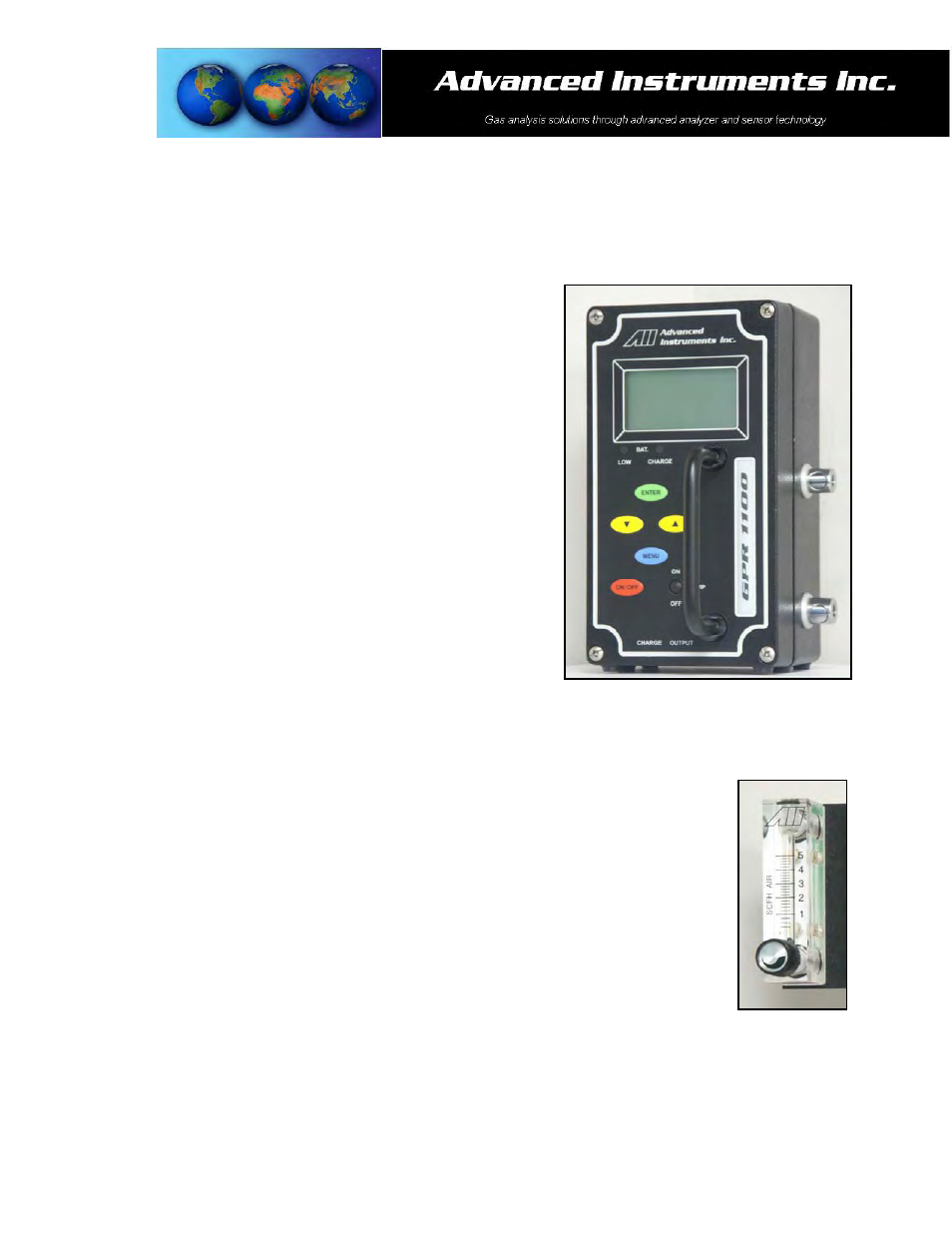

Flow Through Configuration:

The sensor is exposed to sample gas that must flow or be drawn

through metal tubing inside the analyzer. The GPR-1100 internal

sample system includes a quick disconnect female inlet fitting, a

stainless steel sensor housing with an o-ring seal to prevent the

leakage of air and another quick disconnect female vent fitting.

Mating male quick disconnect fittings are provided for introducing

sample and calibration gases, a third male fitting is provided for the

vent line.

Flow rates of 1-5 SCFH cause no appreciable change in the oxygen

reading. However, flow rates above 5 SCFH generate backpressure

and erroneous oxygen readings because the diameter of the

integral tubing cannot evacuate the sample gas at the higher flow

rate. The direction the sample gas flows is not important, thus

either female fitting can serve as the inlet or vent – just not

simultaneously.

A flow indicator with an integral metering valve upstream of the

sensor is recommended as a means of controlling the flow rate of

the sample gas. A flow rate of 2 SCFH or 1liter per minute is

recommended for optimum performance.

Caution: Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is

flowing to the sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage

the sensor (voiding the sensor warranty).

To avoid generating a vacuum on the sensor (as described above) during operation, always

select and install the vent fitting first and remove the vent fitting last.

Application Pressure - Positive:

A flow indicator with integral metering valve (GPR-1100M option) positioned upstream of the

sensor is recommended for controlling the sample flow rate between 1-5 SCFH.

If necessary, a pressure regulator (with a metallic diaphragm is recommended for optimum

accuracy, the use of diaphragms of more permeable materials may result in erroneous

readings) upstream of the flow control valve should be used to regulate the inlet pressure

between 5-30 psig.