Analytical Industries GPR-1200 ATEX Portable Trace PPM Oxygen Analyzer User Manual

Page 10

10

Electronics

The signal generated by the sensor is processed by state of the art low power micro-processor based digital circuitry. The first

stage amplifies the signal. The second stage eliminates the low frequency noise. The third stage employs a high frequency filter

and compensates for signal output variations caused by ambient temperature changes. The result is a very stable signal.

Sample oxygen is analyzed very accurately. Response time of 90% of full scale is less than 10 seconds (actual experience may

vary due to the integrity of sample line connections, dead volume and flow rate selected) on all ranges under ambient

monitoring conditions. Sensitivity is typically 0.5% of full scale low range. Oxygen readings may be recorded by an external

device via the 0-1V signal output jack.

Power is supplied by an integral rechargeable lead acid battery which provides enough power to operate the analyzer

continuously for approximately 60 days. An LED located on the front panel provides a blinking 72 hour warning to recharge the

battery. A 9VAC adapter (positive pole located on the inside of the female connector) can be used to recharge the battery from

a 110V or 220V convenience outlet. The analyzer is designed to be fully operational during the 8-10 hour charging cycle which

is indicated by a second continuously lit LED.

Sample System

The GPR-1200 is supplied with a unique bypass sample system which enables the user to isolate the sensor from exposure to

high oxygen concentration which results in a substantial increase is user productivity. However the sample must be properly

presented to the sensor to ensure an accurate measurement.

For ppm trace oxygen measurements, the sensor is exposed to sample gas that must flow or be drawn through the analyzer’s

internal sample system. This unique sample system, when operated accordingly to the instructions in this Owner’s Manual, can

significantly increase user productivity by minimizing the sensor’s exposure to ambient air or high oxygen concentrations which

contribute to the significant amount of downtime associated with competitive analyzers.

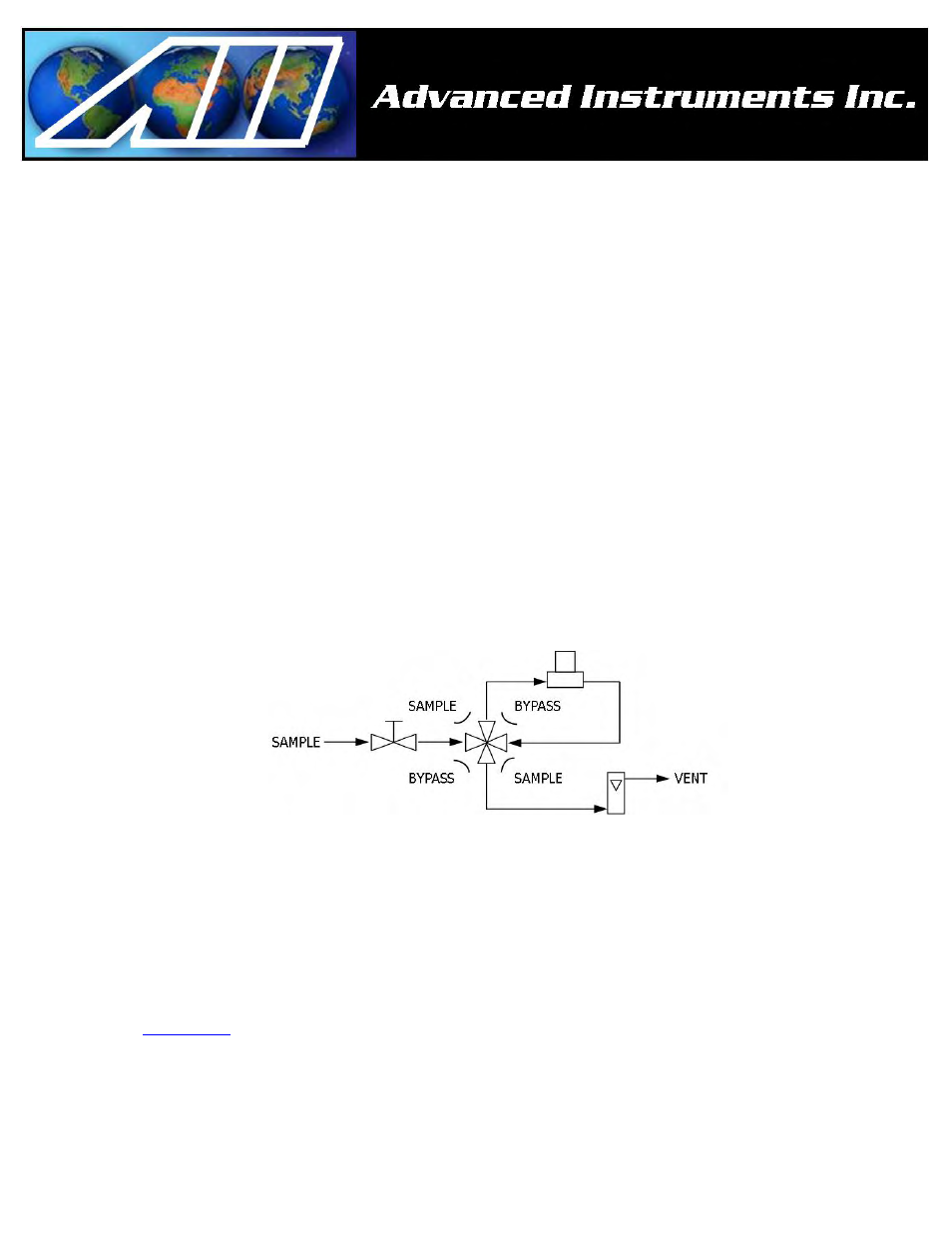

As illustrated above, the GPR-1200’s internal sample system includes:

¾ 1/8” tube fittings for the inlet and outlet

¾ flow control metering valve

¾ 4-way sample/bypass valve to purge lines and isolate the sensor

¾ Stainless steel sensor housing with an o-ring seal to prevent the leakage of air

¾ Flow indicator common to bypass and sample lines

Users interested in adding their own sample conditioning system should consult the factory. Advanced Instruments Inc. offers a

full line of sample handling, conditioning and expertise to meet your application requirements. Contact us at 909-392-6900 or e-

mail us at