Advanced instruments inc, Calibration & accuracy overview – Analytical Industries GPR-1900 Series Trace PPB Oxygen Analyzer User Manual

Page 7

Advanced Instruments Inc.

7

However, for optimal performance after exposing the sensor to air or elevated oxygen levels in terms of:

1) bringing the analyzer back online, and,

2) maximizing the service life of the sensor by isolating the sensor

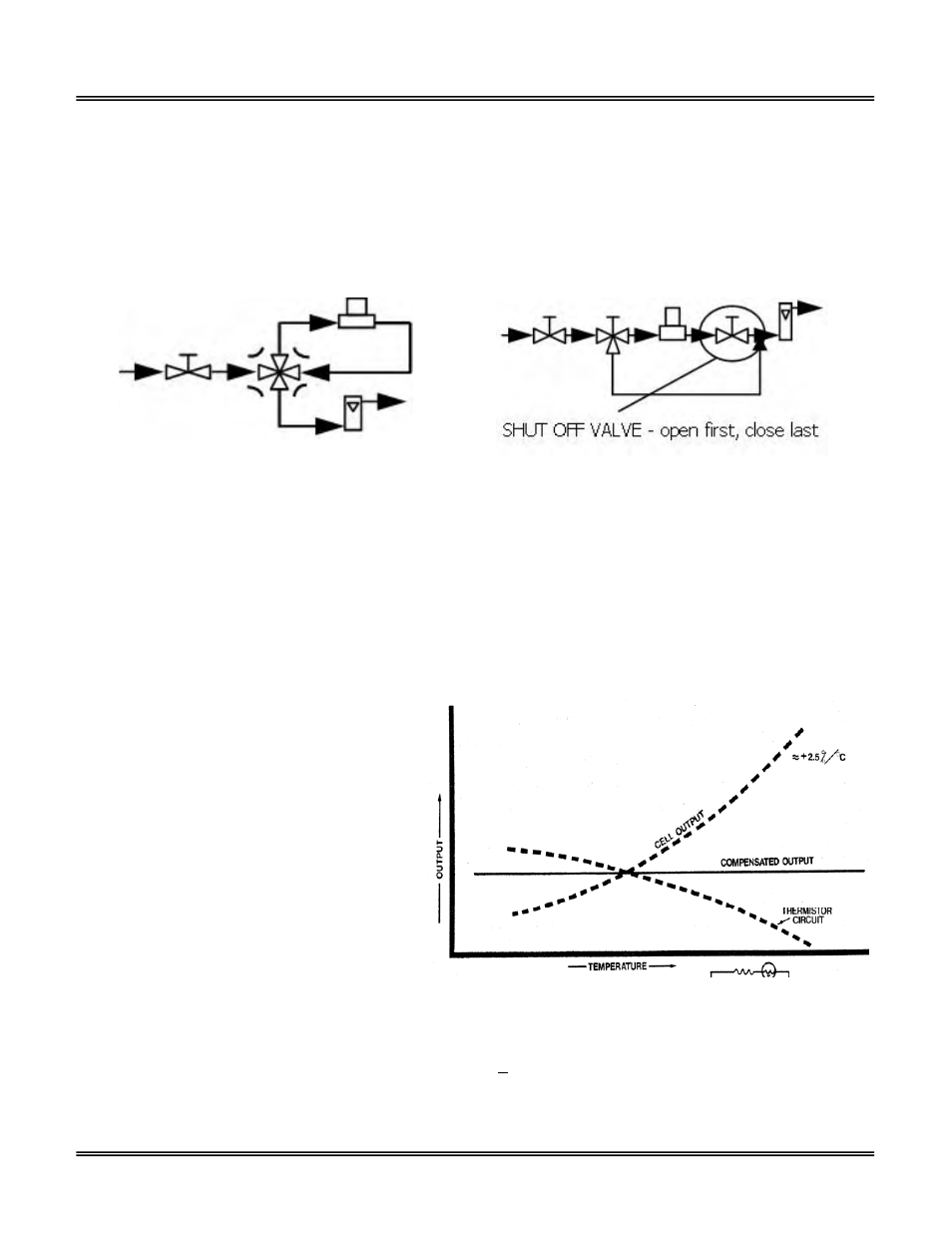

Advanced Instruments recommends the user employ one of the following ‘bypass sample system’ designs illustrated below.

Preference is given to the illustration on the left because it is the surest and simplest approach.

The ‘bypass sample system’ is optimal, however, it is not required. For example, deleting the 3-way valve from the illustration

on the right enables the user to isolate the sensor but lengthens the time required to bring the analyzer online. The bypass

feature diverts the flow of sample gas containing high concentrations of oxygen around the sensor – which when the valves are

operated properly remains in an atmosphere containing a low concentration of oxygen, less than 100-200 ppm. The source of

the atmosphere with the low concentration of oxygen can be either be a zero gas or sample gas is not important - only the

oxygen concentration is important. Without the bypass feature, the sensor still can be isolated but not as easily and the best the

user can do when connecting a new gas line is start the flow of sample gas (to purge the air trapped inside the line) several

minutes before connecting to the analyzer.

Calibration & Accuracy Overview

Single Point Calibration: As previously described

the galvanic oxygen sensor generates an electrical

current proportional to the oxygen concentration in

the sample gas. In the absence of oxygen the sensor

exhibits an absolute zero, e.g. the sensor does not

generate a current output in the absence of oxygen.

Given these linearity and absolute zero properties,

single point calibration is possible.

Pressure: Because sensors are sensitive to the

partial pressure of oxygen in the sample gas their

output is a function of the number of molecules of

oxygen 'per unit volume'. Readouts in percent are

permissible only when the total pressure of the

sample gas being analyzed remains constant. The

pressure of the sample gas and that of the calibration

gas(es) must be the same (reality < 1-2 psi).

Temperature: The rate oxygen molecules diffuse into the sensor is controlled by a Teflon membrane otherwise known as an

'oxygen diffusion limiting barrier' and all diffusion processes are temperature sensitive, the fact the sensor's electrical output

will vary with temperature is normal. This variation is relatively constant 2.5% per ºC. A temperature compensation circuit

employing a thermistor offsets this effect with an accuracy of +5% or better and generates an output function that is

independent of temperature. There is no error if the calibration and sampling are performed at the same temperature or if the

measurement is made immediately after calibration. Lastly, small temperature variations of 10-15º produce < 1% error.