GC EUROPE Kalore User Manual

Page 36

36

7mm

2mm

GC Kalore technical manual

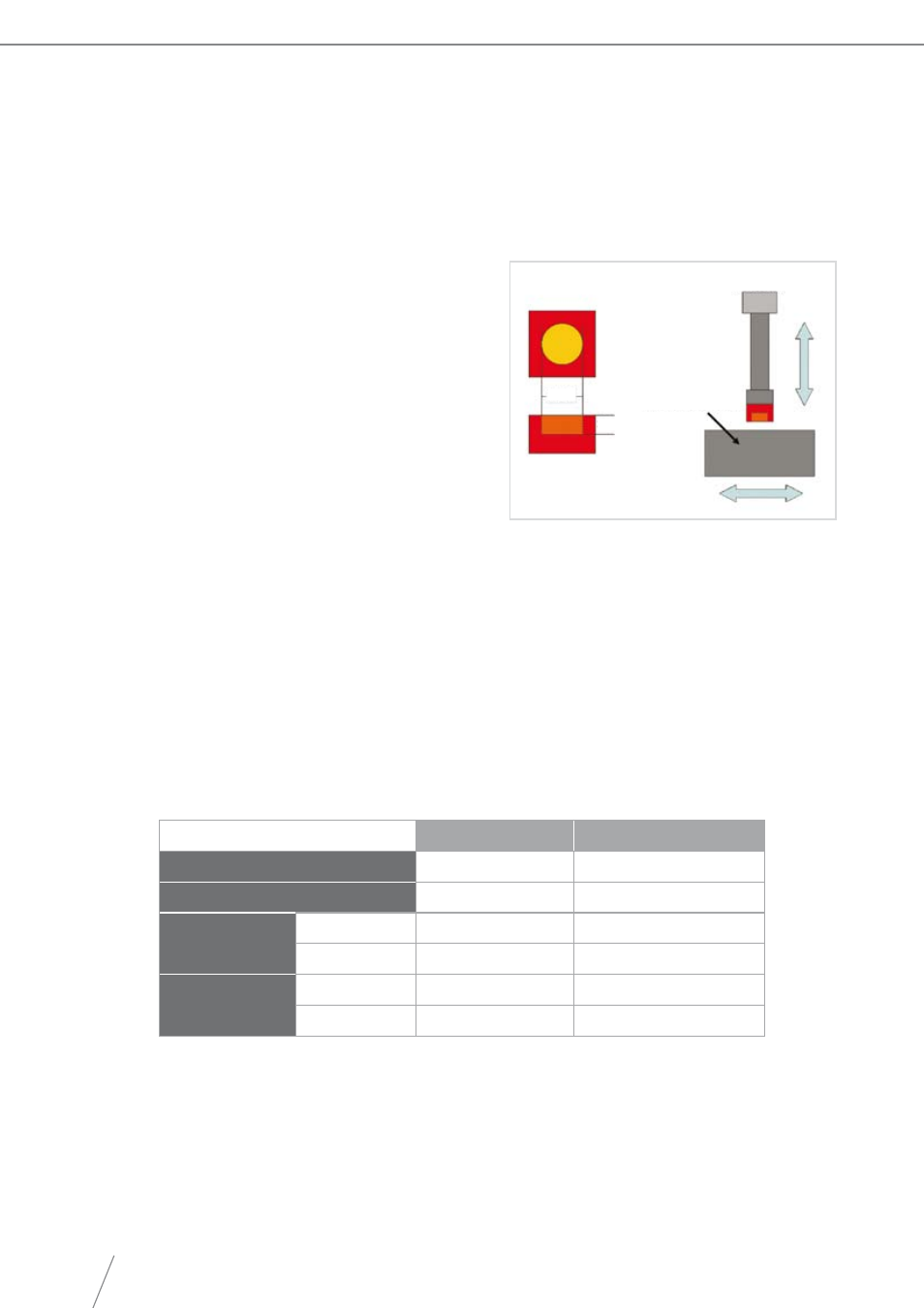

3. combined polish retention/surface roughness test

composite samples were prepared in an acrylic mold

and their surfaces polished using sandpaper with #80,

#180, #320, #600, #1000, #1500 and #2000 grits,

followed by final polishing with a buff and 1µm

alumina. after measuring the surface gloss rates, the

samples were moved up and down along a 4 cm path

at a rate of 30 strokes per minute and held in indirect

contact with an acrylic plate under a load of 350 gf

load. Simultaneously, the sample holder was moved

horizontally along a 2 cm path at a rate of 30 strokes

per minute. A mixture of PMMA and glycerol (1:1

volume) was used as an intermediate abrasive. after

100,000 cycles (one complete lateral and vertical

movement counts as one cycle, and 100,000 cycles is

equivalent to between two and ten years of wear), the

surface gloss was measured. Subsequently, samples

of the composites were processed for SEM imaging.

in addition, composite samples were scanned using

confocal laser microscopy (CLSM) to assess surface

roughness (Ra) before and after the polish retention

test.

Results and Discussion

Results of the shrinkage stress, wear property, polish

retention and surface roughness measurements are

shown in table 2.

Table 2. Shrinkage stress, wear and surface gloss test results.

Shrinkage Stress Results

The shrinkage stress of KALORE measured 8.3N, which was 12% less than the shrinkage stress of

KALORE without DuPont which was 9.5N. This test confirmed that incorporation of the new low

shrinkage monomer (DX-511) reduces shrinkage stress.

Figure 3. combined polish retention/surface roughness test set-up.

KalORe

KalORe without DuPont

Shrinkage Stress (N)

8.3

9.5

Wear Test (μm)

15.9 (2.3)

16.3 (5.9)

Gloss Retention

(Gloss Rate) (%)

after Polish

80.1 (4.2)

76.0 (4.5)

after stress

78.2 (4.8)

70.4 (4.1)

Surface Roughness

(Ra) (μm)

after Polish

0.019 (0.001)

0.047 (0.008)

after stress

0.027 (0.004)

0.059 (0.011)

PMMA/glycerol slurry

350 gf load