0 summary, 0 addendum – GC EUROPE Kalore User Manual

Page 34

34

GC Kalore technical manual

13.0 Summary

KalORe is a state-of-the-art, direct composite resin designed for anterior and posterior direct

restorations. The incorporation of the proprietary monomer DX-511 has enabled optimization of

the physical properties of the composite material.

KalORe offers reduced polymerization shrinkage and polymerization stress. in laboratory testing,

KalORe demonstrated the lowest shrinkage stress of all composites tested. Furthermore, this

innovative direct composite resin possesses excellent handling properties, working time and curing

depth. it also offers high durability, wear resistance and polishability.

KalORe gives the clinician the ability to optimize esthetics for direct composite restorations. the

availability of universal, opaque and translucent shades makes it possible to restore cavities using

either a single- or multi-shade layering technique, while specialized shades are available to

optimize esthetics in cases with increased translucency, shading or bleached enamel.

Direct composite restorations with unrivaled esthetics as well as excellent mechanical and physical

properties are now possible with KalORe.

14.0 Addendum

Influence of the new DuPont monomer (DX-511) on the longevity of GC KALORE.

GC Corporation R&D. May 2009

Introduction

During polymerization of

composite resin, the resin matrix

reduces in volume while the

particles retain their pre-

polymerization volume. this results

in stress at the filler and resin

matrix interface. This stress remains

within the cured composite resin

and can lead to early replacement

of restorations, as particles will be

lost from the matrix. To reduce

polymerization stress at the filler/

matrix interface, lower levels of

polymerization shrinkage are

required.

Recently, a new low shrinkage monomer (DX-511) was licensed from DuPont by GC Corporation.

DX-511 reduces volumetric shrinkage of the resin matrix and, consequently, should minimize both

the generation of stress at the filler/matrix interface and the loss of particles from the resin matrix.

to confirm this hypothesis, composite samples were prepared with (KalORe) and without (KalORe

without DuPont) the low shrinkage monomer. Both materials were formulated with identical fillers,

using the same filler sizes, distribution and treatment (table 1).

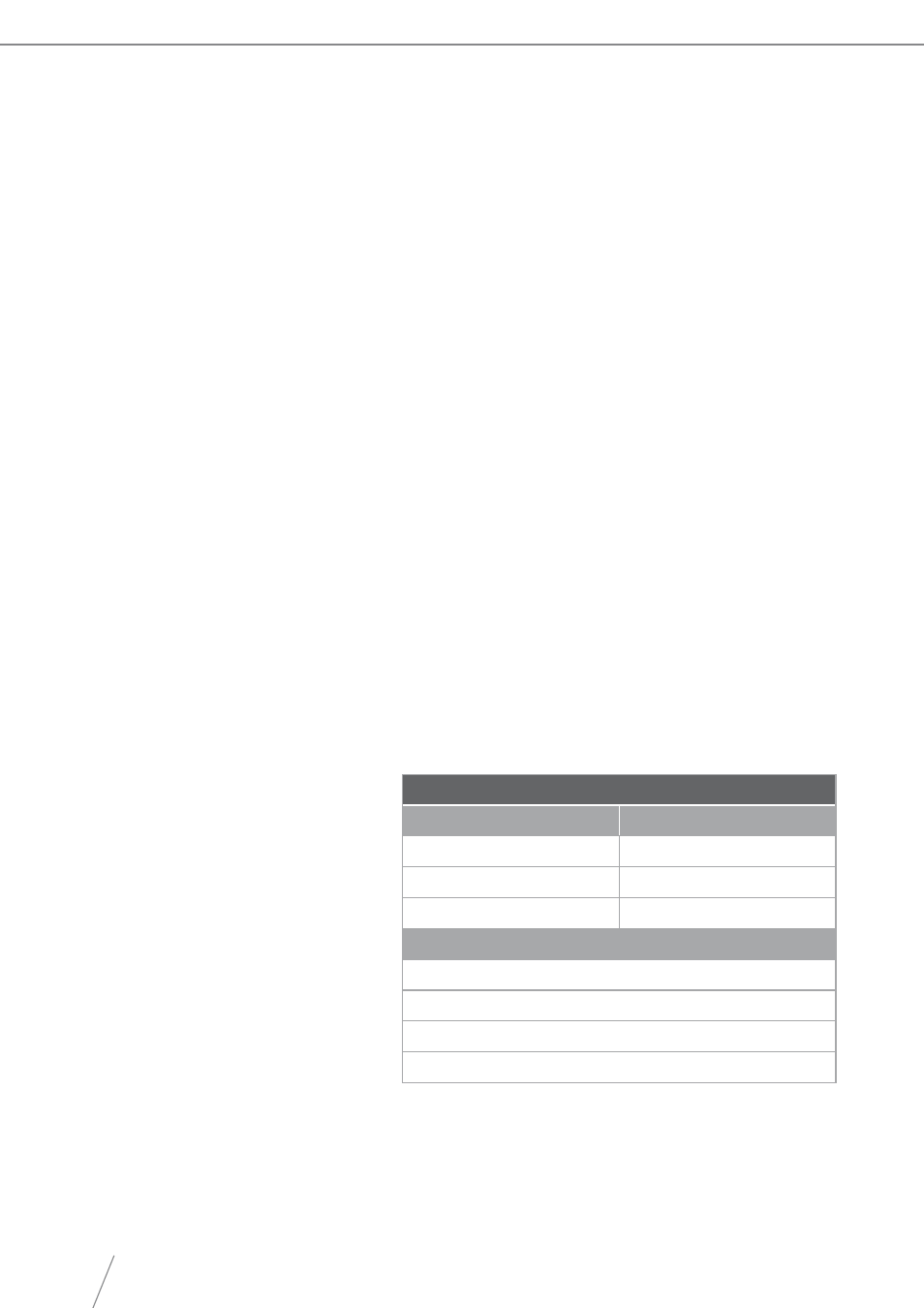

table 1. Formulation of KalORe and KalORe without DuPont

monomer Formulation

KalORe

KalORe without DuPont

uDma

uDma

Dimethacrylate

Dimethacrylate

DX-511 (low shrinkage monomer)

70.4 (4.1)

Fillers and Particle Sizes (identical for KALORE & KALORE without

Fluoroaluminosilicate glass (silanated) 700 nm

Strontium glass (silanated) 700 nm

Pre-polymerized filler (surface treated) 17 μm

Silicon dioxide (silanated) 16 nm