6 three-body wear resistance, Gc kalore technical manual, Kalore grandio† tetric evoceram† tph3 – GC EUROPE Kalore User Manual

Page 20

20

3 Body Wear (µm)

0

50

100

150

200

250

Filtek Supreme DL

†

Filtek Z250

†

Filtek Silorane

†

Prisma TPH3

†

EsthetX

†

Premise

†

4 Seasons

†

Grandio

†

Tetric Evoceram

†

Venus

†

CeramX Mono

†

KALORE

KALORE

Grandio†

Tetric Evoceram†

TPH3†

1mm

2mm

2mm

2mm

7mm

GC Kalore technical manual

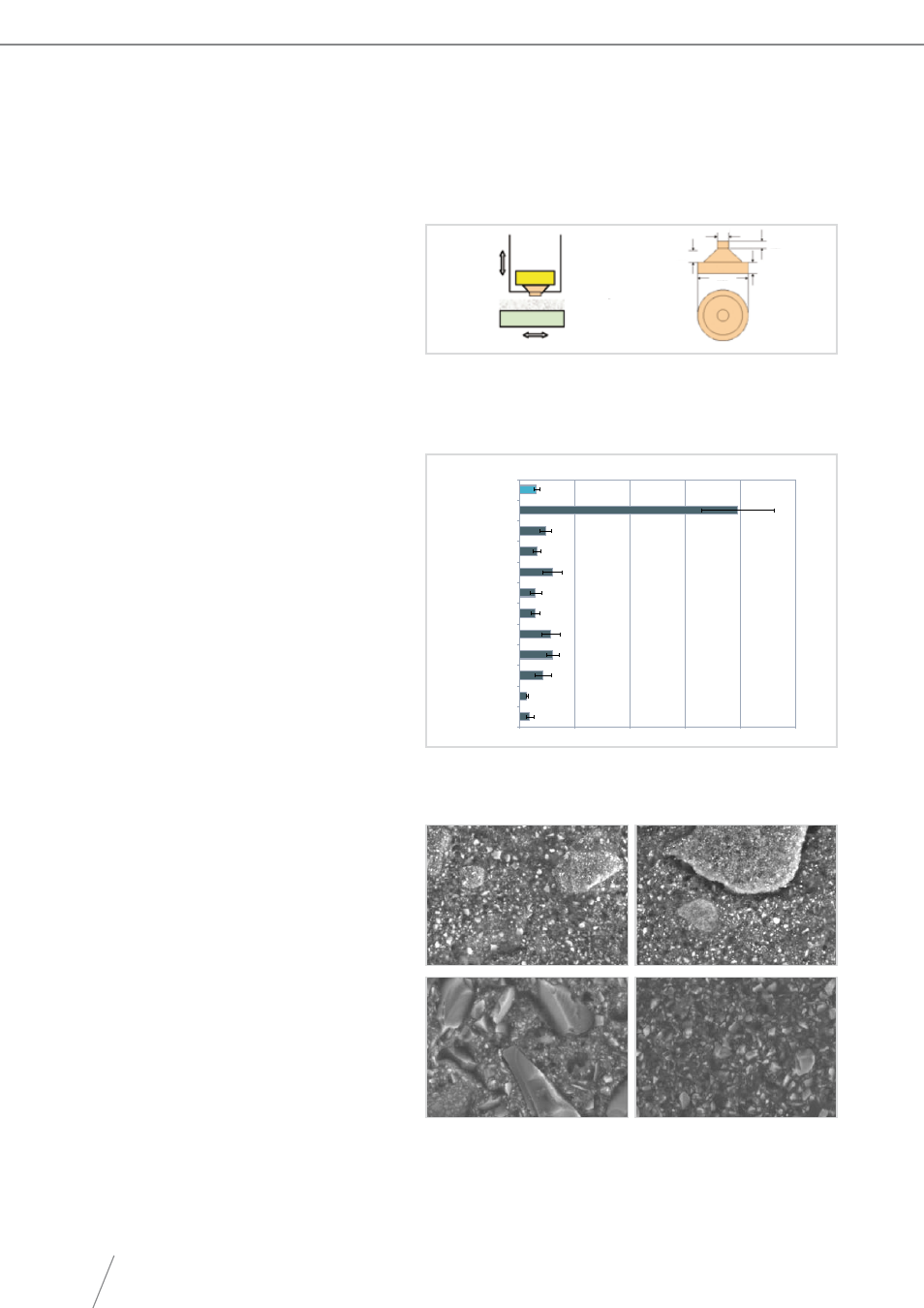

6.6 Three-Body Wear Resistance

to measure three-body wear resistance

in-house, composite specimens were

prepared and moved up and down

along a 5 cm path at a rate of 30 strokes

per minute. they were held in indirect

contact with an acrylic plate under a

load of 350 gf and, simultaneously, the

sample holder slid horizontally along a

2 cm path at a rate of 30 strokes per

minute. A mixture of PMMA and glycerol

(1:1 volume) was used as an intermediate

abrasive (Fig. 20). after 100,000 cycles

(with one complete lateral and vertical

movement being defined as one cycle),

material wear was evaluated by

measuring height loss. KALORE was

found to have high resistance to

three-body wear (Fig. 21).

Following this test, samples of

composites were processed for SEM

imaging. KALORE was found to have

durable and tight bonding between

the fillers and the resin matrix. In the

same

test,

other

products

demonstrated defects at the pre-

polymerized

filler

interface

(EvoCeram†) or at the interface with

the glass particle (Grandio† and

TPH3†). In addition, filler dropouts

were observed (Fig. 22).

Figure 21. three-body wear of various composite materials.

Source: GC Corporation.

Figure 20. three-body wear resistance test set-up.

Figure 22. SEM images of samples tested for three-body wear resistance (x5000).

Sample holder

Composite slurry

Acrylic plate