GC EUROPE G-aenial Bond User Manual

Page 26

26

0

5

10

15

20

25

30

35

40

24 h

20 000TC

24 h

20 000 TC

Etch (-)

Etch (+)

Shear bond strength (MPa)

G-ænial Bond Technical Manual

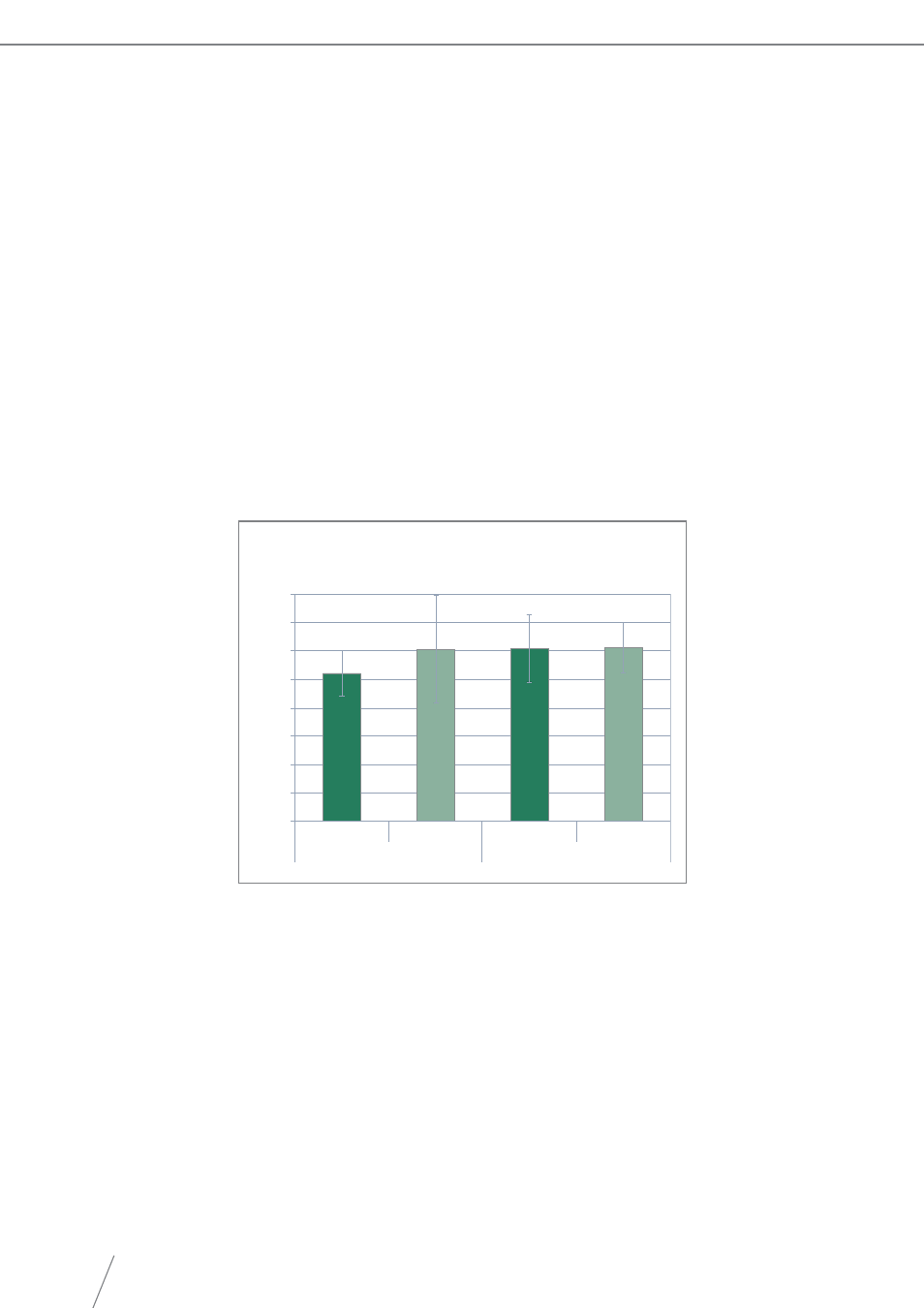

Shear bond strength to enamel

Tests performed by GC R&D, Japan

the purpose of the following study was to assess the adhesion properties of G-ænial Bond with

and without phosphoric acid etching (aet). the resulting shear bond strength (SBS) tests were

conducted at 24 hours and after 2000 cycles of thermocycling.

Test set-up: Bovine enamel specimens were polished with 320-grit Sic paper. For the etch(+) group, etching was conducted

for 10 seconds with a 37% phosphoric acid etching gel (link master etchant, Gc). no etching agent was apply to the etch (-)

surfaces. G-ænial Bond was then applied to the surfaces of the etch (+) and etch (-) groups according to the manufacturer’s

instructions. Clearfil AP-X (Kuraray) was placed on the surface using an Ultradent mould (D=2.38mm) and light-cured. The

specimens were stored in 37°C water for 24 hours. The thermocycling specimens were subjected to thermocycling (5°C-55°C

and 20,000 cycles) after water storage. Shear bond strength (SBS) was measured at a cross-head speed of 1 mm/min. the

statistical analysis was conducted using the tukey test (P<0.05).

Figure 22: influence of etching on shear bond strength to enamel. Source: Gc corporation, Japan, 2009

Shear bond strengths (SBSs) to enamel increased with phosphoric acid etching.

Phosphoric acid etching (AET) improved the bond strength of G-ænial Bond to enamel.

however, after thermocycling, there were no significant differences in the bonding values.

influence of etching on shear bond strength to enamel