Billet Specialties Power Steering Hose Kit for Pump Mount Reservoir User Manual

Page 2

500 Shawmut Avenue • La Grange, Illinois 60526 • Tech Line 708/588-0505 • Fax 708/588-7181

Step 2: Measure For Hose

Double check your measurements.

Measure twice, cut once.

Measure the length needed from the pressure side of the pump to the rack/box.

Keep in mind tight bends in the hose are not recommended and may pinch off supply

select the appropriate fitting to route the hose as straight as possible.

Pressure line length

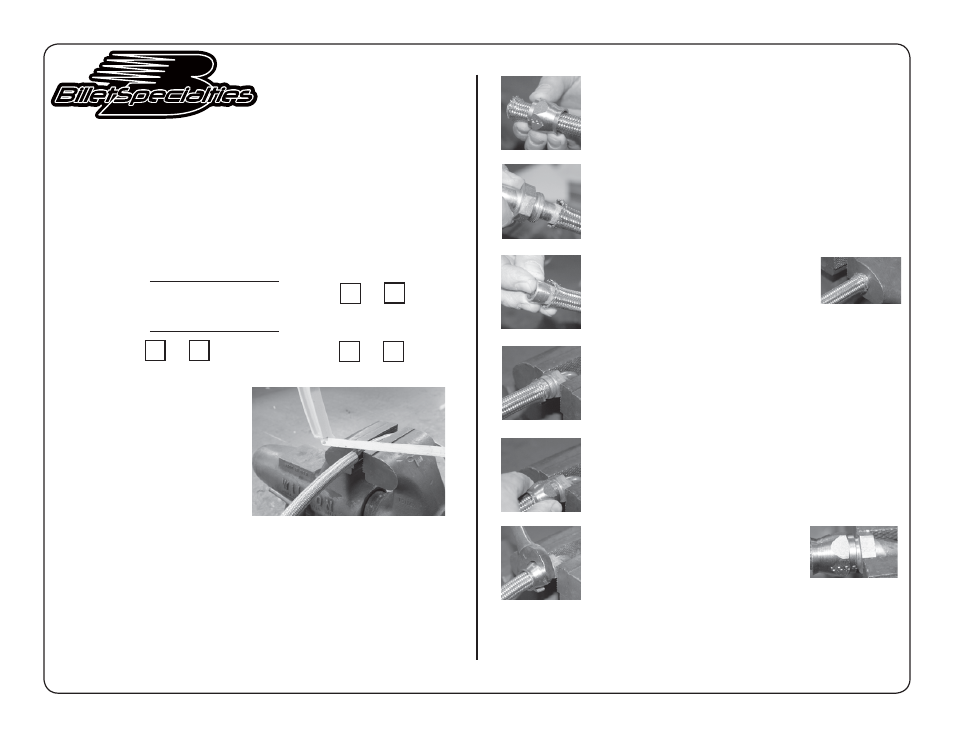

Step 3: Cutting The Hose

Start by tightly wrapping electrical tape around the hose in the area to be cut.

Place hose in a vise without crushing it. Cut hose square to length with a Fine tooth hack

saw or cut off wheel (

Important! Make sure that your cut is square!).

Remove hose from vise and remove tape slowly. Deburr the inner Teflon hose and trim

away any stray stainless braid.

Blow out the inside of the hose to clear any debris. Debris that is left in the line may

cause substantial damage.

Mark your measurements below.

Fitting to pump (must use a 90° fitting) Fitting to rack/box

90°

Straight

Return line length

Fitting to rack/box 90° Straight Fitting to reservoir

90°

Straight

Step 4: Assemble Hose Ends to Hose

Install the threaded socket end on the hose and slide it back

out of the way.

Insert the nipple portion of the hose end into the Teflon part

of the hose to size it back up to shape then remove it.

Push the brass ferrule around the Teflon and

in between the braided hose. Seat the Teflon

hose squarely against the bottom of the ferrule;

this can be done by pushing the hose and sleeve

against a workbench or vise.

Example

Follow by placing the hose end in a vise, sparingly lubricate

the threads with 30wt oil or similar lubricant.

Insert the hose over the nipple making sure the ferrule does

not pop off the Teflon tube.

Finish by threading the socket end onto the nipple by hand.

Clean the hose and blow out with compressed air to clear any debris.

Now tighten with a wrench until the gap

between the nipple and the socket is no more

than 1/16”.

Step 5: Install Hoses

Install hose assembly to each component. Check and make sure the lines are

free and clear of any moving parts.

Example