Using the fiber optic termination kit, Crimping the fiber optic termination kit – Ocean Optics Fiber Optic Termination Kit User Manual

Page 2

Fiber Optic Termination Kit Instructions

2

637-03500-000-01-201105

DFPOLISH-003 – 12 µm lapping film 4.5 in. x 4 in. Al Oxide 4 sheets cut

DFEPOXY – Room temperature ½ hour cure adhesive

DFWIPES – Optic wipes

DFCRIMPTOOL – 5-cavity crimp tool (0.105 in., 0.137 in., 0.151 in., 0.178 in., 0.255 in.)

DFPLATE – 6 in. x 6 in. glass with four rubber feet

DFMICROSCOPE – Basic inspection scope

DFMS SMA – 9025 SMA scope adapter

DFSMACONN – Assortment of 50/100, 200, 400, 600, and 1000 µm SMA connectors (4

each)

DF-LUNCH CASE – Blue carrying case

Using the Fiber Optic Termination Kit

Polishing and finishing a fiber is a two-step process. You must first attach and crimp the SMA

connector onto the fiber (if working with a jacketed fiber). Once completed, you then polish the end of

the fiber to ensure that light can pass through the fiber unobstructed and enter or exit the fiber.

The following sections provide instructions on crimping fiber cables and polishing fiber ends.

Crimping the Fiber Optic Termination Kit

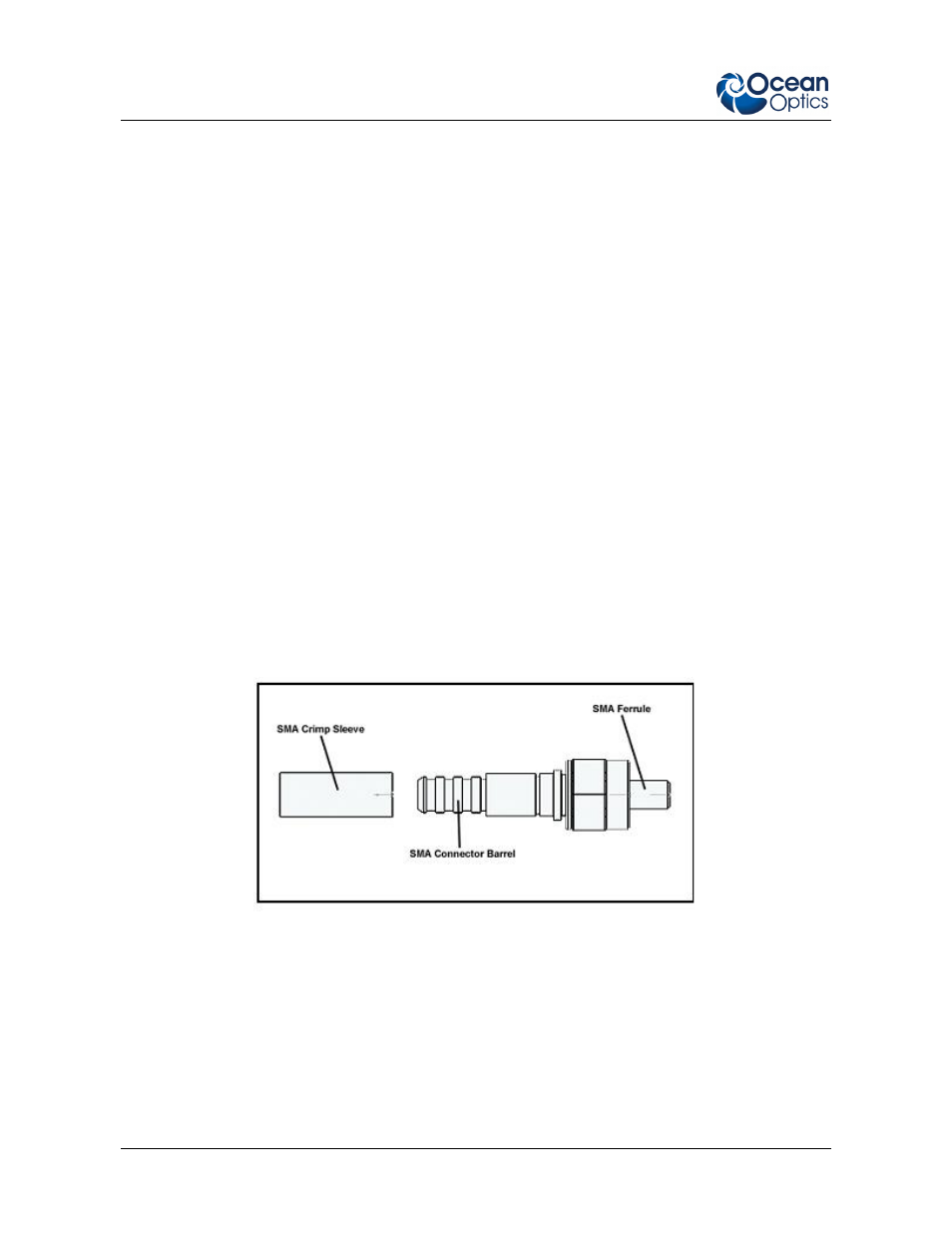

The figure below shows the various portions of the SMA connector that you will use when crimping a

fiber cable:

Parts of the SMA Connector

The Fiber Optic Termination Kit can be used to change or repair fibers and connectors on jacketed

fibers as well as bare fibers. The SMA crimp sleeve is only required when working with jacketed

fibers, which are composed of an outer jacketing (typically PVC or Tefzel), a strength layer composed

of durable Kevlar fibers, and a black inner tube coating that protects the fiber from damage and

insulates against stray light.

Figure 2 below illustrates the composition of a typical jacketed fiber: