Optional equipment, Cd (cylinder dogging), Preparation chart – Factory Direct Hardware Von Duprin 9847EOF3 User Manual

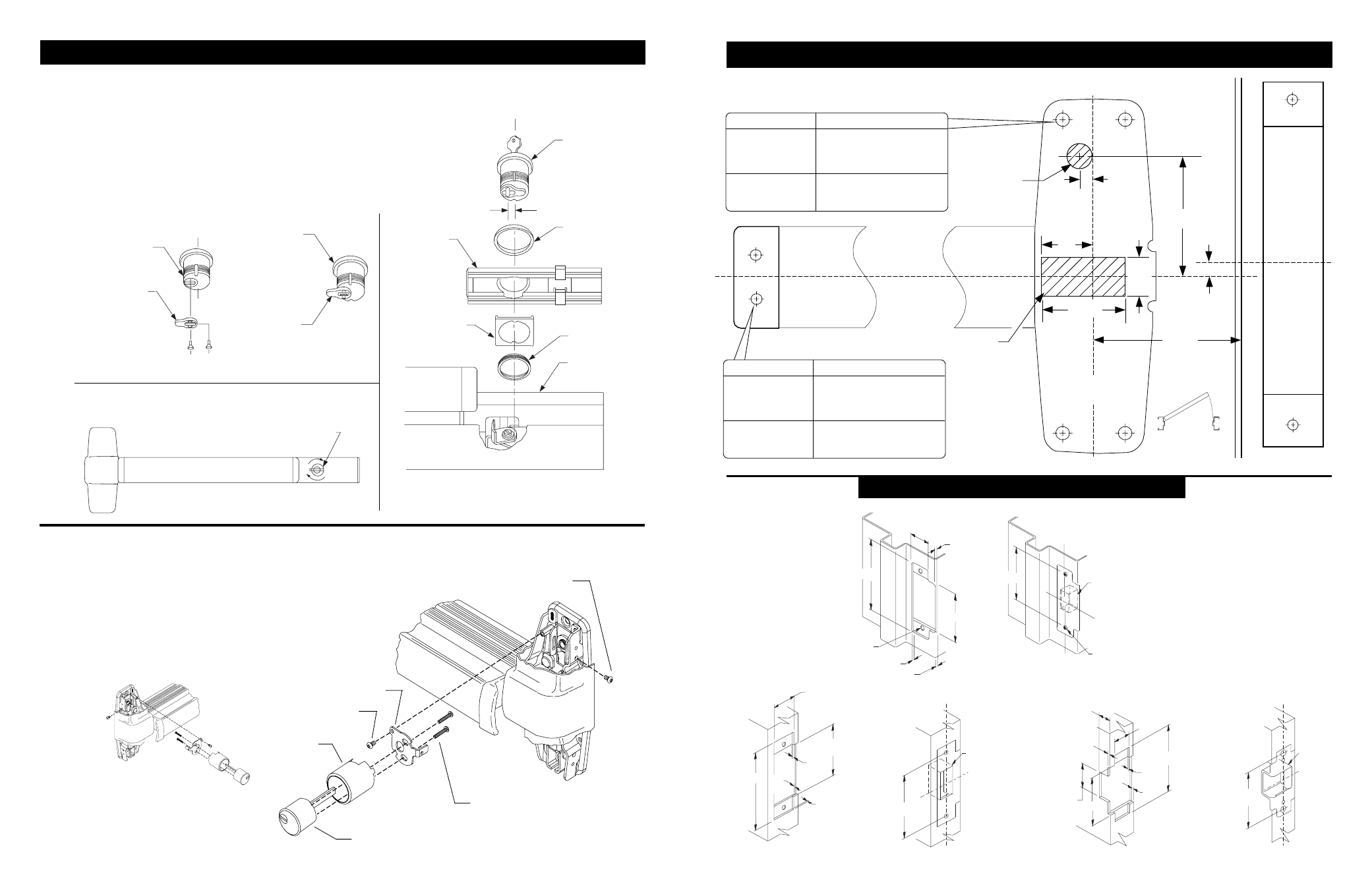

Page 3: Strike preparation, Figure 1 figure 2, Dogging procedure, Center case - 4 holes, End cap bracket - 2 holes

98/9975-2 (DOUBLE CYLINDER) - RHR SHOWN

1. Remove center case cover.

2. Mount rim cylinder to cylinder bracket as shown.

3. Mount cylinder and bracket assembly to center

case with two #8 screws as shown.

PREPARATION CHART

3

1"

4 7/8"

1 1/4"

1/8"

Deep

1/8"

Deep

2 1/16"

3 3/8"

3/16"

Deep

CL

4 1/8"

4 1/8"

CL

of Lock & Strike

CL

of

Latch Bolt

Cutout 1" Deep

on Wood Door

5/32" Dia. Drill Pilot

for Wood Frame

CL

of Lock

CL

of Latch

Bolt

Cutout 1"

Deep on

Wood Door

4 1/8"

1/8"

Deep

1/8"

Deep

1/8"

Deep

3 3/8"

4 1/4"

4 7/8"

1/8" Deep

1/8" Deep

3 3/8"

1 1/4"

4 7/8"

1/8" Deep

#16 Drill

#12-24 Tap

of Lock

575 Strike

575-2 Strike

576A/B Strike

1”

1-5/8”

1/4”

2-1/4”

2-3/4”

O

utermost door edge

B

eveled edge

Cut-out

For all 98/9975

devices

1/2” dia. hole

for 98/9975-2

double cylinder

devices only

3/4”

Device

Device

CL

CL

11/32”

Mortise

lock

CL

STRIKE PREPARATION

6

X

X

OPTIONAL EQUIPMENT

1. Remove mortise cylinder cam and

reinstall in reverse (Figure 1).

2. Insert key and rotate cam to install

the cylinder to the cover plate (Figure 2).

3. Remove key to slide cover plate in

position in the mechanism case.

Std. mortise

cylinder

Mortise

cylinder

cam

Std. mortise

cylinder

Mortise

cylinder

cam

CD function conversion

Figure 1

Figure 2

Std. mortise

cylinder

Cylinder

collar

Dogging

plate cover

Offset toward

pushbar

Cylinder

locating washer

Cylinder

lock nut

Mechanism

case

Turn cylinder key clockwise approx. 1/8

turn for standard dogging

Dogging procedure

Depress pushbar

CD (CYLINDER DOGGING)

Center case - 4 holes

Surface mount

Sex bolts or 990 trims

#25 Drill

#10-24 tap

1/8” Drill

pilot 1” deep

1/4” Drill (device side)

13/32” Drill (trim side)

13/32”

Drill thru

Metal

W

ood

Metal

W

ood

Surface mount

Sex bolts

#25 Drill

#10-24 tap

1/8” Drill

pilot 1” deep

1/4” Drill (device side)

13/32” Drill (trim side)

13/32”

Drill thru

Metal

W

ood

Metal

W

ood

*End cap bracket - 2 holes

RHR Shown

(LHR opposite)

Go to instructions on next page before using Preparation Chart

*Prepare end

cap holes after

lock side of

device is

mounted and

hinge side of

device is leveled

Cylinder

Spacer

Rim Cylinder

Cylinder Bracket

#8-32 X 5/16”

PPHMS

Cylinder Mounting Screws

(do not over-tighten)

#8-18 x 3/8” PPHSMS

LHR