Factory Direct Hardware Von Duprin 98EO User Manual

Page 4

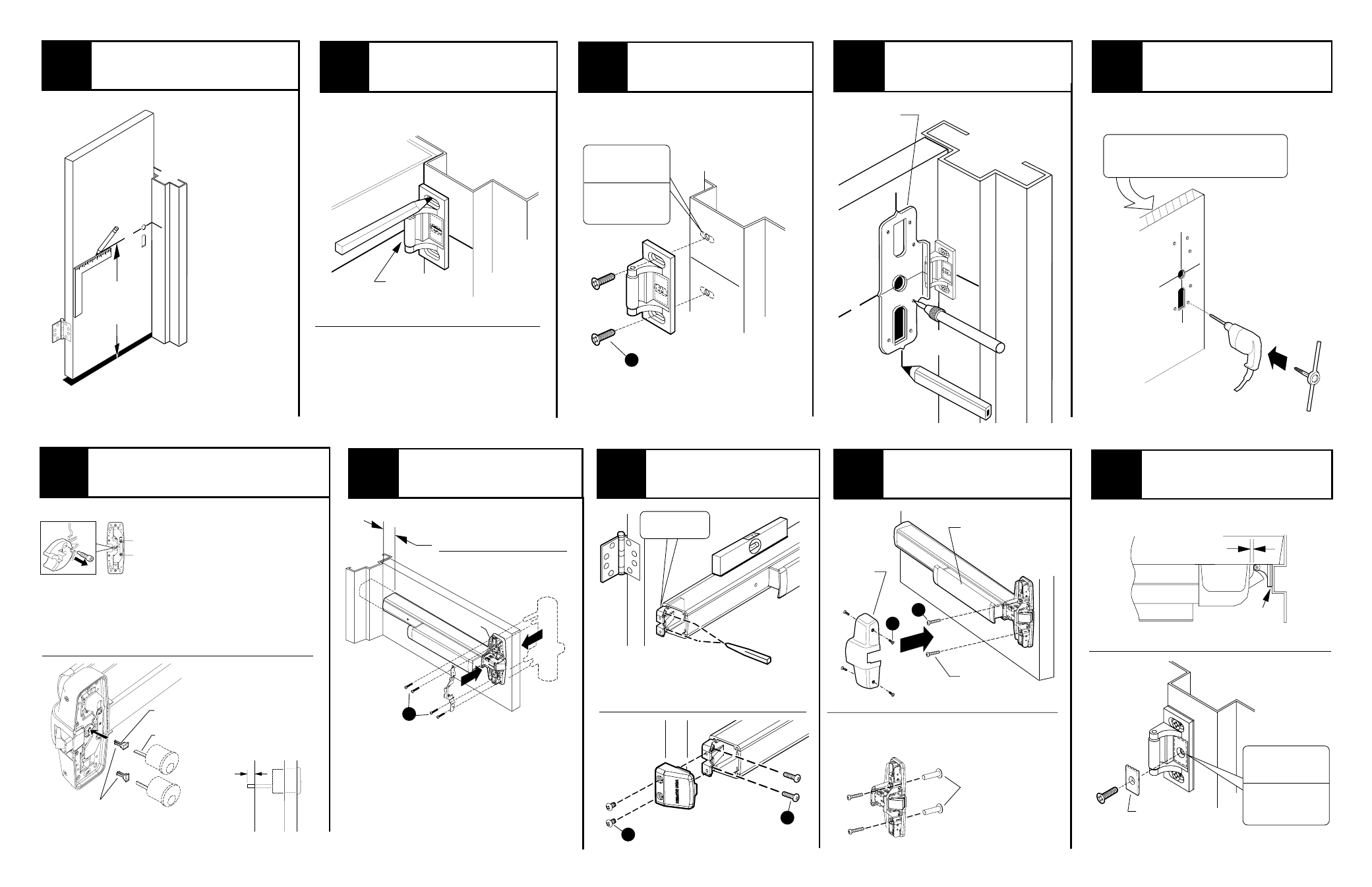

5

1

*39-13/16”

To finished

floor

RHR Shown

(LHR opposite)

2

3

4

9

7

9

10

Position template against strike

and on C and mark door.

Prepare lock side of door

for device and trim.

See “Preparation Chart” on page 3 for

drill, tap, and cut-out information

Install trim (if using) and secure

device center case to door.

Install 2 support screws,

and center case cover.

Adjust and secure strike.

Shim for 3/16”

if shimming is

necessary

299/299F Strike

Prepare 2 holes and install

a screw thru each slot.

299/299F Strike

299/299F Strike

CL

CL

Align strike on C and mark

the two slotted holes.

L

Draw horizontal device and

strike center line (C ).

L

Center

case

cover

Support

screws (2)

For 499F strike, see back

cover of this instruction.

L

3/16”

Strike plate

(299 only)

Roller

(against door)

4

5

Template

(align on C and

against strike)

L

CL

center

case

Trim

(optional)

1-1/2” Minimum clearance

(with end cap removed)

if device is too long for

door, see “Cut Device”

on back cover

A

B

E

F

See “Screw Chart” on page

2 for screw types and sizes

Remove protective

film from pushbar

For 98F/99F (fire rated) devices on

wood or composite door:

#825 sex bolts

required for 2

support screws

CL

X

X

Mark 6

holes

Mark

vertical CL

*For double doors with a

mullion and strike already

installed, use existing

strike center line.

#25 Drill

#10-24 tap

1/8” Drill

pilot 1” deep

Metal

W

ood

#25 Drill

#10-24 tap

1/8” Drill

pilot 1” deep

Metal

W

ood

8

Install mounting bracket

and end cap.

Secure

mounting bracket

and end cap

Mounting

bracket flush

Level device

Mark and prepare 2

mounting holes

See “Preparation Chart” on

page 3 for preparation

C

D

5

Cut tailpiece

if needed

1/2”

Door

surface

6

Tailpiece

Tailpiece guide

Rotate tailpiece

guide to match

tailpiece

If using an outside cylinder, check NL

drive screw and install tailpiece guide.

When installing trim that has a

functional lever, knob, or thumb piece

AND an outside cylinder to lock and

unlock the trim, remove NL drive screw

from back of device.

DO NOT remove NL drive screw for

the following application:

NL, EO, DT, TP-2, L-2, and K-2 trims or

with 98/99-2 (double cylinder).

With “BE” trim, device may need

rehanded. Look for instructions on

back of trim.

Note: When the NL

drive screw is left in

back of device, the

outside cylinder

will function only

as a Night Latch.

NL drive screw

See trim instructions for pull side door

preparation. Line X-X in trim instructions

is same as vertical device C .

L