Dexter Laundry T-120 (On-Premise) User Manual

Page 7

- 7 -

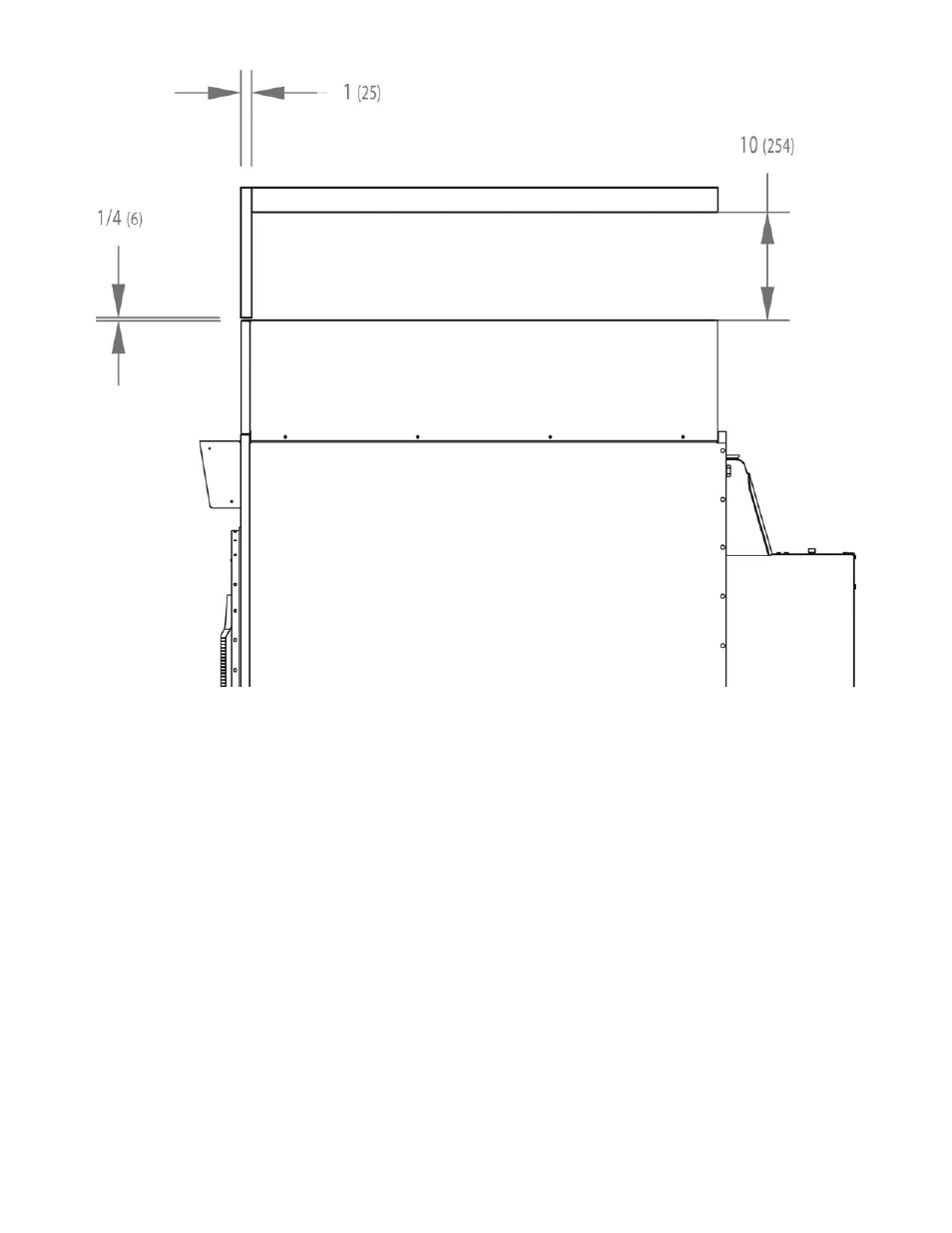

VERTICAL CLEARANCE DIMENSIONS

3. MAKE-UP AIR. Adequate make-up air (

1250

CFM (35.4 m³/minute) for 60 Hz machines with 10” exhaust,

1450 CFM (41 m³/minute) for 60 Hz machines with 12” exhaust,

1000

CFM (28.3 m³/minute) for 50 Hz machines

with 10”/12” exhaust) must be supplied to replace air exhausted by dryers on all types of installations. Provide a

minimum of 2.25 ft² (0.2 m²) make-up air opening to the outside for each dryer. This is a net requirement of

effective area. Screens, grills or louvers, which will restrict the flow of air, must be considered. Consult the supplier

to determine the free area equivalent for the grill being used.

The source of make-up air should be located sufficiently away from the dryers to allow an even airflow to the air

intakes of all dryers. Multiple openings should be provided.

NOTE: The following considerations must be observed for gas dryer installations where dry cleaners are

installed. The sources of all make-up air and room ventilation air movement to all dryers must be located

away from any dry cleaners. This is necessary so that solvent vapors will not be drawn into the dryer

inlet ducts. Dry cleaner solvent vapors will decompose in contact with an open flame such as the gas

flame present in clothes dryers. The decomposition products are highly corrosive and will cause damage

to the dryer(s), ducts and clothes loads.

4.

ELECTRICAL REQUIREMENTS. The electrical power requirements necessary to operate the unit satisfactorily

are listed on the serial plate located on the back panel of each dryer. The electrical connection should be made to

the

terminal block in the rear control box assembly

on the rear of the unit, using a wire size adequate to handle the

amperage and voltage listed on the serial plate, but never smaller than No.12 AWG wire. It is absolutely necessary

that the dryer be grounded to a known ground.

Individual circuit breakers for each unit are recommended. The wiring diagram is located on the belt guard on

the back of the machine.