Heat sink specifications, Th ermal resis tan ce (d eg c/w ) – Ironwood Electronics SG-BGA User Manual User Manual

Page 15

P a g e | 1 5

S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Tel: (800) 404-0204

www.ironwoodelectronics.com

Vibration

Standard:

MIL-STD202, METHOD 204, CONDITION A

No change in resistance and thickness

Humidity

Standard:

MIL-STD202, METHOD 106

Resistance change: 26 m

Thickness change: -1%

Standard:

MIL-STD202, METHOD 103, CONDITION A

Resistance change: 15 m

Thickness change: -6%

Thermal Shock

Standard:

MIL-STD202, METHOD 107, CONDITION A

Resistance change: -19 m

Thickness change: -1%

Heat Sink Specifications

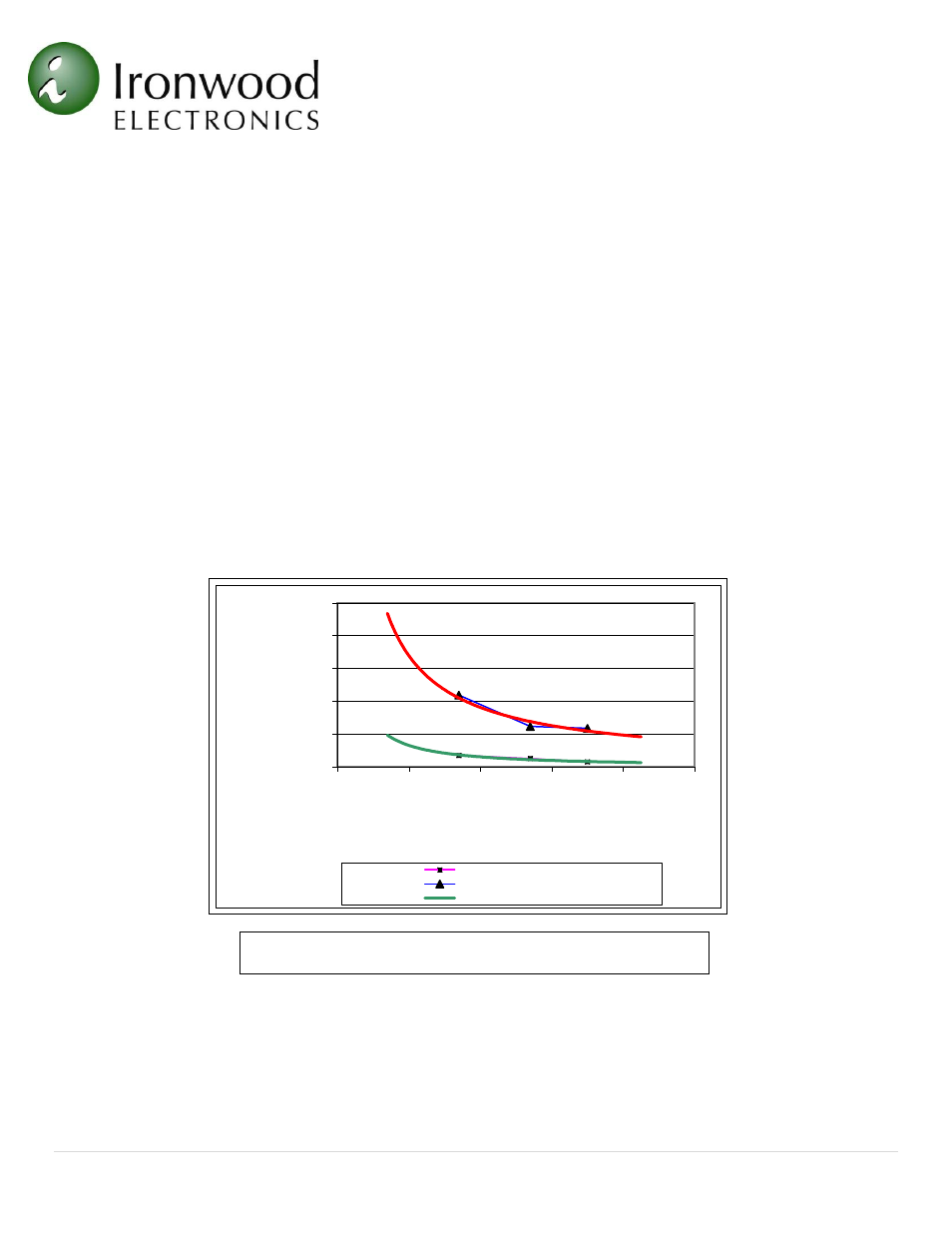

The graph (Figure 15) shows thermal resistance of the socket as well as socket with a fan (Papst 3412/9 GL,

35.9 CFM, 6” muffin) blowing directly on it. For high power dissipation, a specific heat sink lid can be

designed using QFIN software. Please call Ironwood Tech Support @1-800-404-0204.

0

10

20

30

40

50

0

10

20

30

40

50

Th

ermal

resis

tan

ce

(d

eg

C/W

)

IC Size (mm)

Socket+Fan

Socket Only

Trend (Socket+Fan)

Figure 15: Heat Sink Characteristics