C and preferably <10 – Ironwood Electronics SG-BGA User Manual User Manual

Page 11

P a g e | 1 1

S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Tel: (800) 404-0204

www.ironwoodelectronics.com

recommends contacting your solder paste / flux manufacturer for proper reflow profiles for your particular set-

up and equipment.

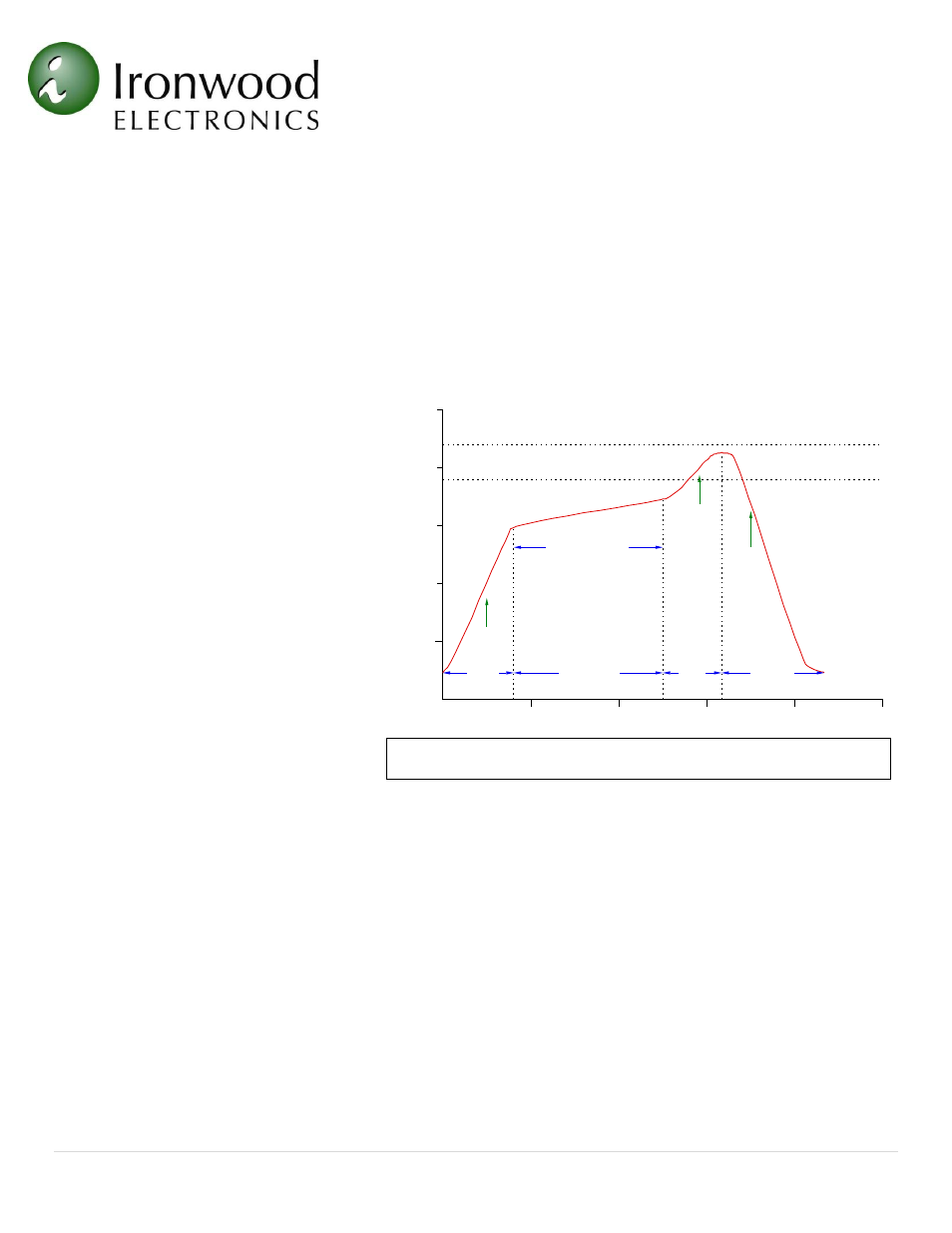

Recommended Reflow Profile – Low Temperature (Non-RoHS)

Ironwood's SMT adaptor closely emulates a BGA package and therefore can employ similar processes to attach

it to a target board. The steps involved in the soldering process are as follows:

(1) Using a flux dispenser, place a small amount of flux (water soluble or no clean) on the middle of the target

PCB lands. Spread the flux evenly over the PCB lands.

(2) Apply a small amount of TAC flux on opposite corners of the PCB lands.

(3) Note the target board land pattern orientation and the SM adaptor Pin 1 location. Place the adaptor (solder

ball side down) onto the flux and land pattern (align as closely as possible to the land pattern of the target PCB).

The SM adaptors are durable enough to

be handled by hand, however vacuum pen

or pick & place equipment can be used

for handling the part.

(4) Surface tension between the adaptor's

solder spheres and the target PCB's pads

will self-align the part during the reflow

process.

(5) Reflow as per (Figure 11):

Use caution when profiling to insure

minimal

temperature

difference

(<15

0

C and preferably <10

0

C)

between components

Forced

convection

reflow

with

nitrogen preferred (50 - 75 PPM)

Preheat stage temperature ramp rate:

<2

0

C per second

Time required in Flux Activation

stage: 150 to 180 seconds

Flux Activation stage temperature range: 150 to 183

0

C

Time required in Solder stage: 60 seconds

Maximum temperature 210 - 220

0

C (Do not exceed 10 seconds at maximum temperature)

Cool-Down stage temperature reduction rate: <20 C/sec

NOTE: It may be necessary to adjust the amount of heat when attaching the part, due to the fact that the adaptor

mass is different from the actual IC package. Solder sphere spec = 63Sn, 37Pb and its melting point = 183 C

(6) Clean PCB with the flux manufacturers recommended process after reflow. Install the GHz socket on the

SM adaptor as per assembly instruction provided in the GHz socket assembly section.

250

200

150

100

50

0

100

200

300

400

500

Preheat

Flux Activation

Reflow

Cool-Down

<2°C

per Second

150 - 180 Seconds

<2°C

per Second

1° to 3°C

per Second

Time (seconds)

T

em

p

er

at

u

re

(°

C

)

Maximum Package Body Temperature

Solder Temperature Melting Point

Figure 11: Recommended Reflow Profile – non RoHS

Figure 4: Example Insulation Plate