R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist TDU Motorized Trolley User Manual

Page 10

R&M Materials Handling, Inc

LoadMate Chain Hoist

Springfield, Ohio USA

TDU Instruction Manual

(: 800 955-9967

Revision 2

web:

www.rmhoist.com

08/13/02

RM-LM-TDU-MAN-1999-2-ENG.doc

10

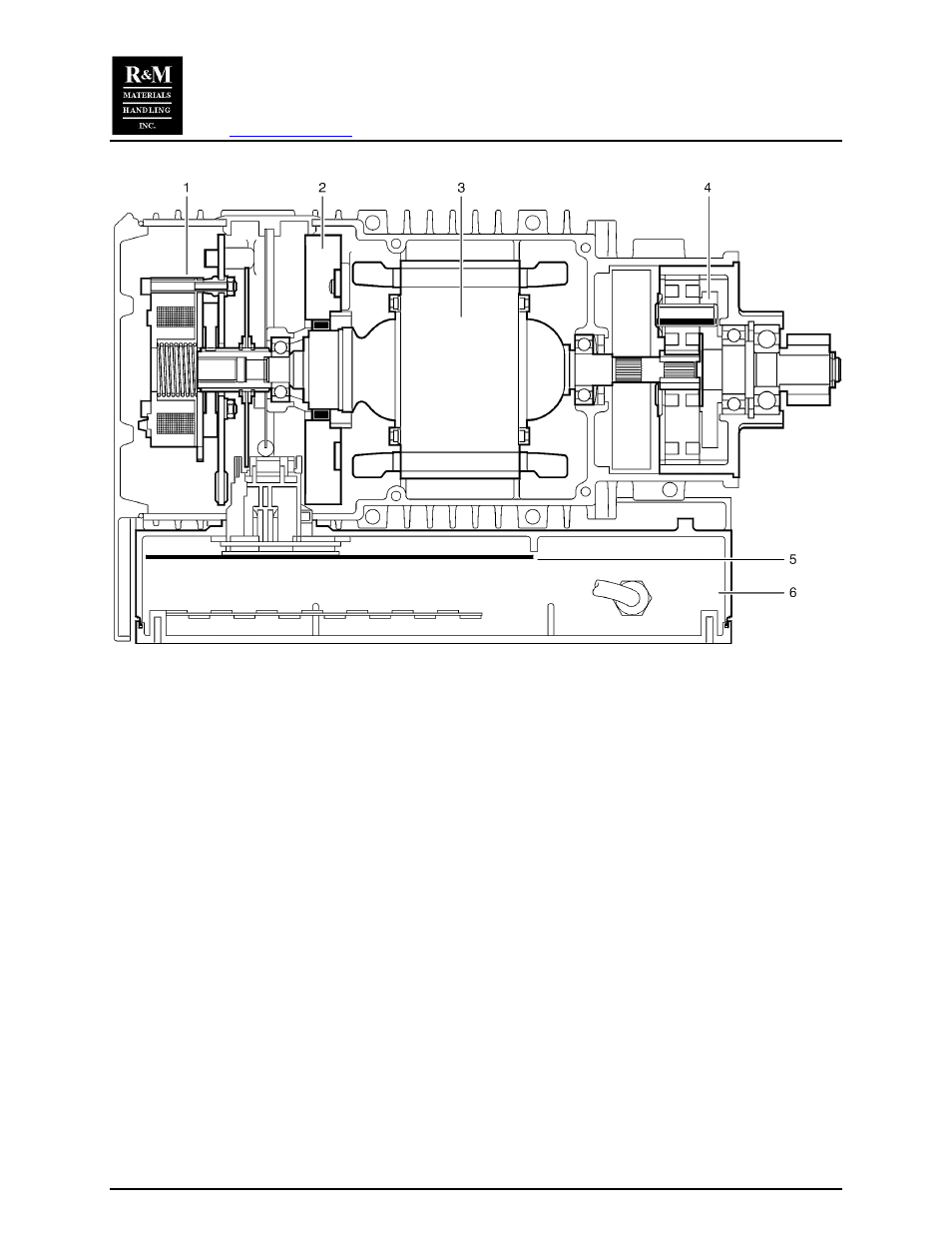

Motor and Brake

1. Brake

Assembly

2. Brushes

3. Rotor

Stator

4. Gear Reducer

5. Printed Circuit Board

6. Control Enclosure

Motor

Two phases of the power supply are used where one phase is always energized.

Reminder:

With reference to the standards, the user must provide an emergency shutdown or mainline

disconnect switch at a maximum of 24 feet from the trolley. On the electric chain hoist, a mainline contactor

is provided in hoist control enclosure as standard.

Note:

If the motor has been in a humid atmosphere, it is advisable to check the insulation resistance. This

should not be less than 5000 ohms per volt of rated voltage.

Brake

Braking occurs when the D.C. coil is de-energized. The asbestos free friction material is on each side of the

disk. The energized coil pulls the disc against the spring and releases the brake. Once the coil is de-

energized the spring applies a clamping force, setting the brake.