3 fault codes, troubleshooting – R&M Materials Handling VARIABLE SPEED CONTROLS CMXC 007 Service Manual User Manual

Page 7

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

7/9

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

3 FAULT CODES, TROUBLESHOOTING

There are high voltages inside the inverter (including the programming switches).

Wait for at least three minutes after the supply voltage has been switched off before

any service actions.

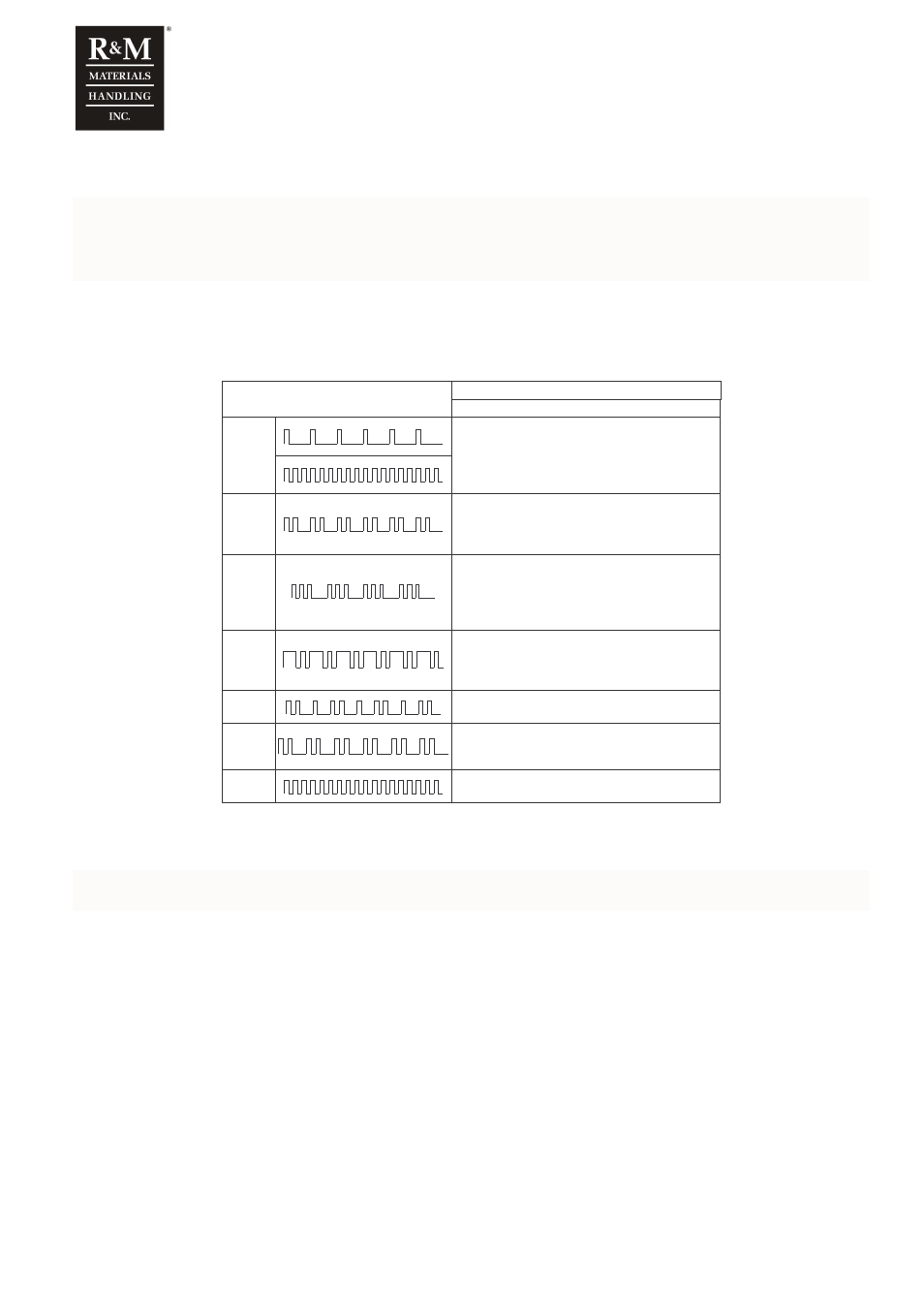

When the inverter detects a fault situation it stops running and starts signalling the fault code by blinking the

indication leds (green and red). The blinking of the code is carried on until a new fault occurs or until power is

switched off. The fault codes are explained in the table below.

Fault code, color

Fault. Possible cause. Checkings.

DMCS007

GREEN

Overvoltage. Mains voltage is too high or ramp

time is too short. Check the voltage of all supply

phases at the terminal X1. If they are ok then

set a longer ramp by switch S3.

GREEN

Stall supervision / overcurrent. Brake does

not open properly or there is an obstackle on

the track. Check also that the setting of switch

S4 is made according to the supplied motor(s).

GREEN

Deceleration ramp supervision. Deceleration

ramp has not been followed. If the fault occurs

again set longer ramp time by switch S3. Check

also the voltage of all supply phases at the

terminal X1.

GREEN

Inverter overtemperature. Motor current is too

high (bearing problem, obstacle on the track,

brake does not open properly,…) or the

ambient temperature is too high.

GREEN

Undervoltage. Check the voltage of all supply

phases at the terminal X1.

RED

Short circuit. Switch the power off. Check the

insulation of the motor cables and the motor

windings.

RED

Microprocessor fault. Switch the power off for

10 seconds. Then power-up the inverter.

The latest active fault is removed from the memory always when power is switched off.

If inverter is not in a fault state, but driving is not possible:

Motor will not start if dc-bus voltage too high (above 745V), this occurs if any of line-to-line voltages exceeds

480V+5% = 508V

o

If line voltage cannot be reduced, install drop-down transformer

Check the supply voltage phases at terminal X1.

Check the control signals at terminal X1.

Check that the control voltage level is correct. Rating plate is located on the left side of the inverter.

Check all parameters, especially the motor parameters (switch S4).

Check that the motor(s) corresponds the selected motor parameters.

Check that the microprocessor starts running. Both indication leds (green and red) blink once as the inverter is

powered up. After the one second initialising-time only the green led should be light.

Check that the brake opens and closes properly. Check the brake airgap if necessary.