Rainbow Electronics MAX5090C User Manual

Page 12

MAX5090A/B/C

2A, 76V, High-Efficiency MAXPower Step-Down

DC-DC Converters

12

______________________________________________________________________________________

where:

I

OUT

is the maximum output current of the converter

and f

SW

is the oscillator switching frequency (127kHz).

For example, at V

IN

= 48V, V

OUT

= 3.3V, the ESR and

input capacitance are calculated for the input peak-to-

peak ripple of 100mV or less, yielding an ESR and

capacitance value of 40m

Ω and 100µF, respectively.

Low-ESR ceramic multilayer chip capacitors are recom-

mended for size-optimized application. For ceramic

capacitors assume the contribution from ESR and capaci-

tor discharge is equal to 10% and 90%, respectively.

The input capacitor must handle the RMS ripple current

without significant rise in the temperature. The maxi-

mum capacitor RMS current occurs at approximately

50% duty cycle. Ensure that the ripple specification of

the input capacitor exceeds the worst-case capacitor

RMS ripple current. Use the following equations to cal-

culate the input capacitor RMS current:

where:

I

PRMS

is the input switch RMS current, I

AVGin

is the

input average current, and

η is the converter efficiency.

The ESR of the aluminum electrolytic capacitor increas-

es significantly at cold temperatures. Use a 1µF or

greater value ceramic capacitor in parallel with the alu-

minum electrolytic input capacitor, especially for input

voltages below 8V.

Output Filter Capacitor

The output capacitor C

OUT

forms double pole with the

inductor and a zero with its ESR. The MAX5090’s inter-

nal fixed compensation is designed for a 100µF capaci-

tor, and the ESR must be from 20m

Ω to 100mΩ. The

use of an aluminum or tantalum electrolytic capacitor is

recommended. See Table 2 to choose an output

capacitor for stable operation.

The output ripple is comprised of

∆V

OQ

(caused by the

capacitor discharge), and

∆V

OESR

(caused by the ESR

of the capacitor). Use low-ESR tantalum or aluminum

electrolytic capacitors at the output. Use the following

equations to calculate the contribution of output capac-

itance and its ESR on the peak-to-peak output ripple

voltage:

The MAX5090 has a programmable soft-start time (t

SS

).

The output rise time is directly proportional to the out-

put capacitor, output voltage, and the load. The output

rise time also depends on the inductor value and the

current-limit threshold. It is important to keep the output

rise time at startup the same as the soft-start time (t

SS

)

to avoid output overshoot. Large output capacitors take

longer than the programmed soft-start time (t

SS

) and

cause error-amplifier saturation. This results in output

overshoot. Use greater than 2ms soft-start time for a

100µF output capacitor.

∆

∆

∆

∆

V

I x ESR

V

I

x C

x f

OESR

L

OQ

L

OUT

SW

=

≈

8

I

I

I

x

D

I

V

I

V

x

I

I

I

I

I

I

D

V

V

PRMS

PK

DC

IPK xIDC

AVGin

OUT x

OUT

IN

PK

OUT

L

DC

OUT

L

OUT

IN

=

+

=

=

+

=

−

=

+

(

)

2

2

3

2

2

η

∆

∆

I

I

I

CRMS

PRMS

AVGin

=

−

2

2

∆I

V

V

V

V

f

L

D

V

V

L

IN

OUT

OUT

IN

SW

OUT

IN

=

−

Ч

Ч

Ч

=

(

)

ESR

V

I

I

C

I

D

D

V

f

IN

ESR

OUT

L

IN

OUT

Q

SW

=

+

=

Ч

−

Ч

∆

∆

∆

2

1

(

)

0

100

200

300

400

500

600

700

800

-40

100

25

125

150

TEMPERATURE (

°C)

V

F_D1

(mV)

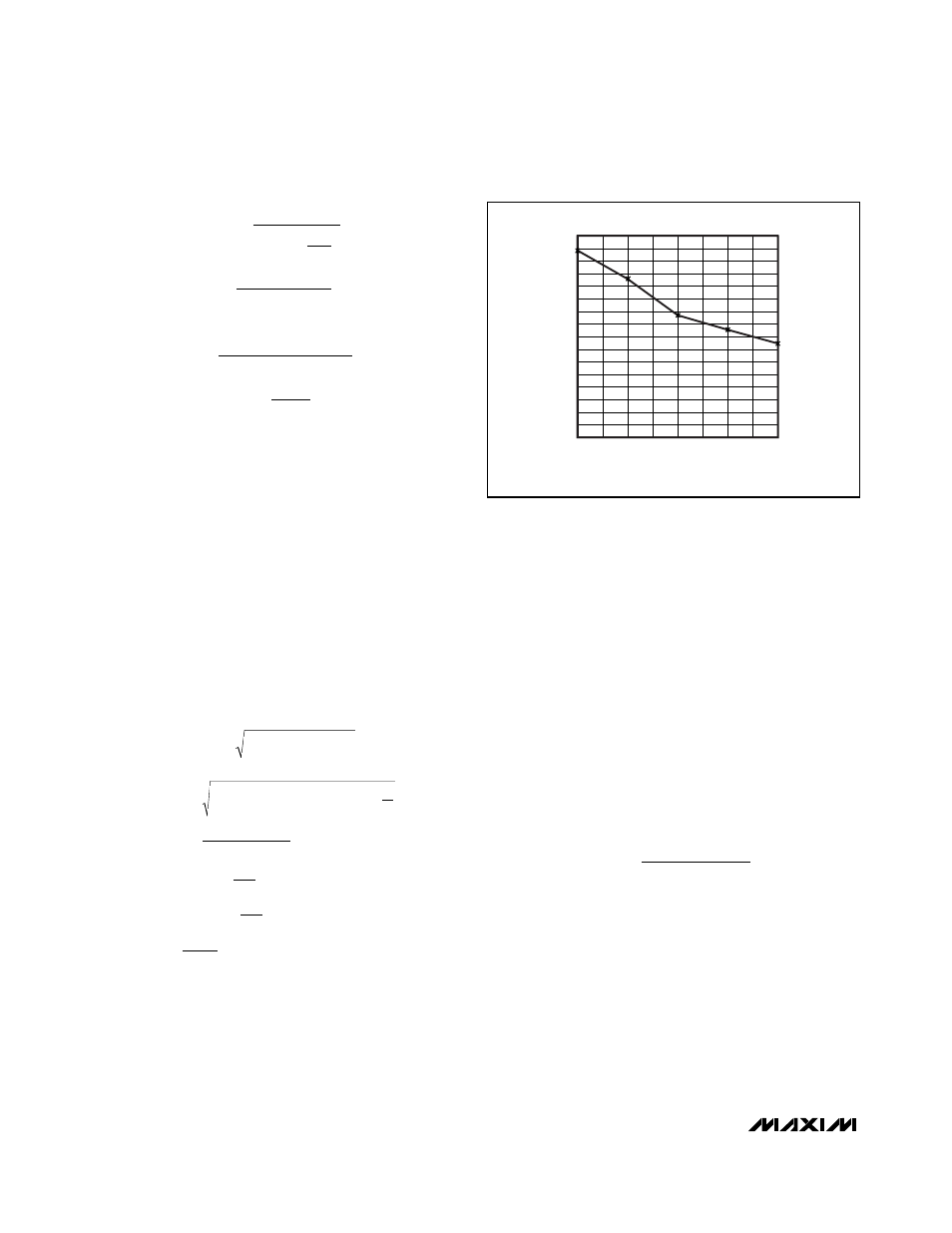

Figure 3. Forward-Voltage Drop vs. Temperature of the Internal

Body Diode of MAX5090