Setting the reset timeout period, Tracker input/feedback adjustment, Electrical characteristics – Rainbow Electronics MAX15010 User Manual

Page 16

MAX15008/MAX15010

Setting the

RESET Timeout Period

The reset timeout period is adjustable to accommodate

a variety of applications. Set the reset timeout period by

connecting a capacitor, C

RESET

, between CT and

SGND. Use the following formula to select the reset

timeout period, t

RESET

:

t

RESET

= C

RESET

x V

CT_TH

/ I

CT

where t

RESET

is in seconds and C

RESET

is in µF.

V

CT_TH

is the CT ramp threshold in volts and I

CT

is the

CT ramp current in µA, as described in the

Electrical

Characteristics

table.

Leave CT open to select an internally fixed timeout peri-

od of 10µs. To maintain reset timeout accuracy, use a

low-leakage (< 10nA) type capacitor.

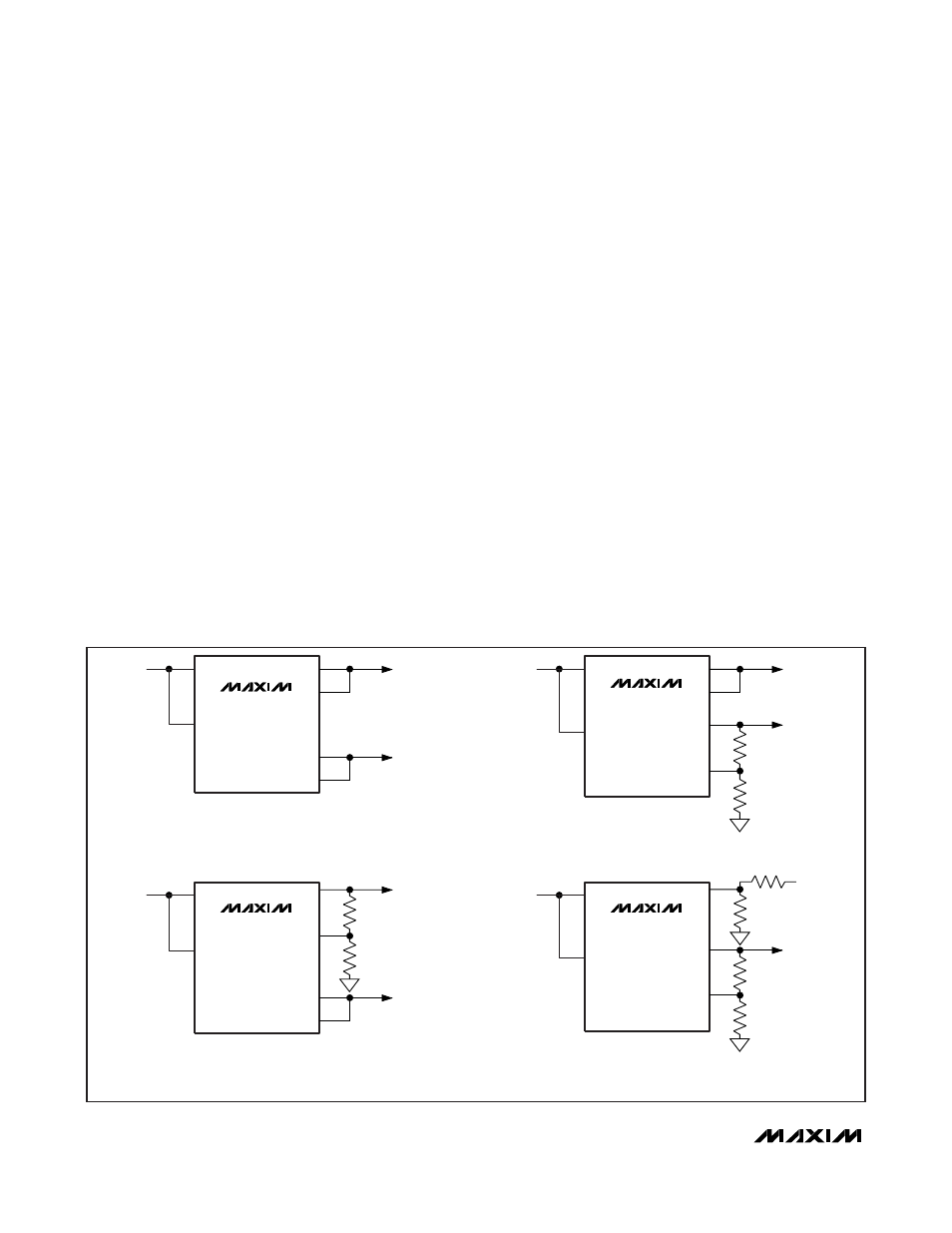

Tracker Input/Feedback Adjustment

The tracker can be powered from the LDO input supply

voltage or an independent voltage source. It is

designed to supply power to a remote sensor and its

supply input, TRACK, is able to handle the severe con-

ditions in automotive applications such as battery

reversal and load-dump transients up to 45V.

The tracker feedback, FB_TRK, and a separate tracker

reference voltage input, ADJ, offer the flexibility of set-

ting the tracker output to be lower, equal to, or higher

than the main (LDO) output. Other external voltages

can also be tracked.

Connect ADJ to OUT_LDO and FB_TRK to OUT_TRK to

track the LDO output voltage directly (Figure 4a). To

track a voltage higher than V

OUT_LDO

, directly connect

ADJ to OUT_LDO and connect FB_TRK to OUT_TRK

through a resistive voltage-divider (Figure 4b). To track

a voltage lower than the LDO regulator output,

V

OUT_LDO

, directly connect FB_TRK to OUT_TRK and

connect ADJ to OUT_LDO through a resistive voltage-

divider (Figure 4c). To track an external voltage V

X

with

a generic attenuation/amplification ratio, connect resis-

tive voltage-dividers between ADJ and the voltage input

or output to be tracked (V

X

), and between OUT_TRK

and FB_TRK (Figure 4d). Pay attention to the resistive

loading of the voltage V

X

due to the divider R5, R6.

To track the internal REF voltage (1.235V), directly connect

ADJ to REF. The voltage at FB_TRK or ADJ should be

greater than or equal to 1.1V and less than V

TRACK

- 0.5V.

Resistors should have a tolerance of 1% or better. Their

values should be low enough to ensure that the divider

current is at least 100x the maximum input bias current

at pins FB_TRK and ADJ (I

FB_TRK_ADJ

, max = 0.2µA).

Automotive 300mA LDO Voltage Regulators

with Tracker Output and Overvoltage Protector

16

______________________________________________________________________________________

IN

LDO

OUTPUT

V

IN

OUT_TRK

OUT_LDO

TRACKER

OUTPUT

FB_TRK

ADJ

MAX15008

MAX15010

TRACK

IN

LDO

OUTPUT

R3

V

IN

OUT_TRK

OUT_LDO

TRACKER

OUTPUT

ADJ

MAX15008

MAX15010

R4

FB_TRK

R5

R6

R6

TRACK

TO TRACK V

OUT_LDO

:

V

OUT_TRK

= V

OUT_LDO

TO TRACK A VOLTAGE HIGHER THAN

V

OUT_LDO

:

V

OUT_TRK

= V

OUT_LDO

x (R3 + R4) / R4,

R3 + R4 < V

OUT_TRK

/ 20

μA

(a)

(b)

IN

LDO

OUTPUT

V

IN

OUT_TRK

OUT_LDO

TRACKER

OUTPUT

FB_TRK

ADJ

MAX15008

MAX15010

TRACK

IN

R3

V

IN

OUT_TRK

ADJ

TRACKER

OUTPUT

MAX15008

MAX15010

R4

FB_TRK

TRACK

TO TRACK A VOLTAGE LOWER THAN V

OUT_LDO

:

V

OUT_TRK

= V

OUT_LDO

x R6 / (R5 + R6),

R5 + R6 < V

OUT_LDO

/ 20

μA

TO TRACK A GENERIC VOLTAGE V

X

:

V

OUT_TRK

= V

X

x (R6 / (R5 + R6)) x ((R3 + R4) / R4),

R5 + R6 < V

X

/ 20

μA, R3 + R4 < V

OUT_TRK

/ 20

μA

R5

(c)

(d)

V

X

Figure 4. Tracker Input and Feedback Adjustment