Applications information – Rainbow Electronics ADC10064 User Manual

Page 11

Applications Information

1 0 MODES OF OPERATION

The ADC10061 ADC10062 and ADC10064 have two basic

digital interface modes

Figure 1

and

Figure 2

are timing

diagrams

for

the

two

modes

The

ADC10062

and

ADC10064 have input multiplexers that are controlled by

the logic levels on pins S

0

and S

1

when S H goes low

Table I is a truth table showing how the input channnels are

assigned

Mode 1

In this mode the S H pin controls the start of conversion

S H is pulled low for a minimum of 250 ns This causes the

comparators in the ‘‘coarse’’ flash converter to become ac-

tive When S H goes high the result of the coarse conver-

sion is latched and the ‘‘fine’’ conversion begins After

600 ns (typical) INT goes low indicating that the conversion

results are latched and can be read by pulling RD low Note

that CS must be low to enable S H or RD CS is internally

‘‘ANDed’’ with S H and RD the input voltage is sampled

when CS and S H are low and data is read when CS and

RD are low INT is reset high on the rising edge of RD

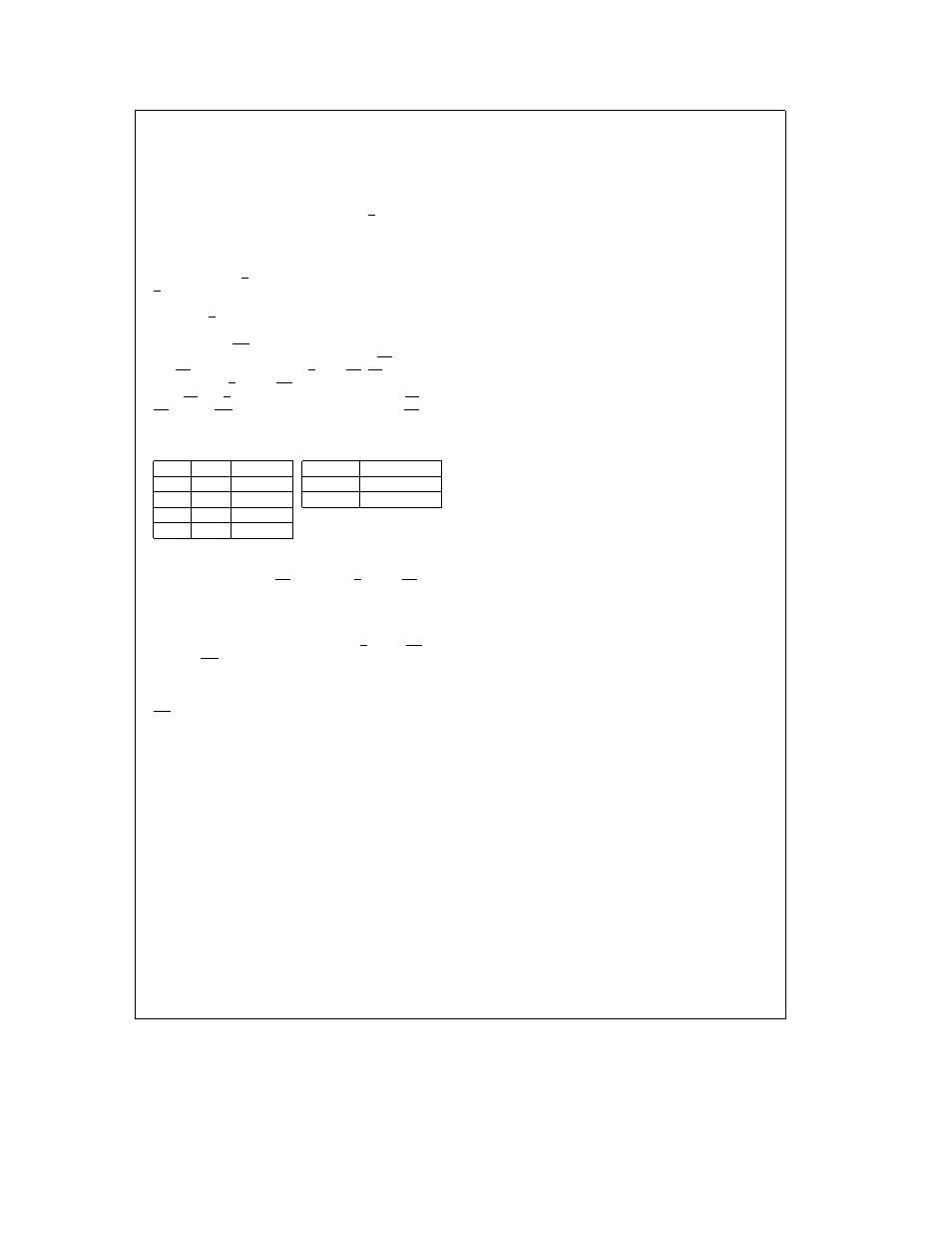

TABLE I Input Multiplexer Programming

ADC10064

ADC10062

S

1

S

0

Channel

S

0

Channel

0

0

V

IN0

0

V

IN0

0

1

V

IN1

1

V

IN1

1

0

V

IN2

(b)

1

1

V

IN3

(a)

Mode 2

In Mode 2 also called ‘‘RD mode’’ the S H and RD pins

are tied together A conversion is initiated by pulling both

pins low The A D converter samples the input voltage and

causes the coarse comparators to become active An inter-

nal timer then terminates the coarse conversion and begins

the fine conversion 850 ns (typical) after S H and RD are

pull low INT goes low indicating that the conversion is

completed Approximately 20 ns later the data appearing on

the TRI-STATE output pins will be valid Note that data will

appear on these pins throughout the conversion but until

INT goes low the data at the output pins will be the result of

the previous conversion

2 0 REFERENCE CONSIDERATIONS

The ADC10061 ADC10062 and ADC10064 each have two

reference inputs These inputs V

REF

a

and V

REF

b

are fully

differential and define the zero to full-scale range of the

input signal The reference inputs can be connected to span

the entire supply voltage range (V

REF

b

e

0V V

REF

a

e

V

CC

) for ratiometric applications or they can be connected

to different voltages (as long as they are between ground

and V

CC

) when other input spans are required Reducing

the overall V

REF

span to less than 5V increases the sensi-

tivity of the converter (e g if V

REF

e

2V then 1 LSB e

1 953 mV) Note however that linearity and offset errors

become larger when lower reference voltages are used

See the Typical Performance Curves for more information

For this reason reference voltages less than 2V are not

recommended

In most applications V

REF

b

will simply be connected to

ground but it is often useful to have an input span that is

offset from ground This situation is easily accommodated

by the reference configuration used in the ADC10061

ADC10062 and ADC10064 V

REF

b

can be connected to a

voltage other than ground as long as the voltage source

connected to this pin is capable of sinking the converter’s

reference current (12 5 mA Max

V

REF

e

5V) If V

REF

b

is

connected to a voltage other than ground bypass it with

multiple capacitors

Since the resistance between the two reference inputs can

be as low as 400X the voltage source driving the reference

inputs should have low output impedance Any noise on ei-

ther reference input is a potential cause of conversion er-

rors so each of these pins must be supplied with a clean

low noise voltage source Each reference pin should be by-

passed with a 10 mF tantalum and a 0 1 mF ceramic

3 0 THE ANALOG INPUT

The ADC10061 ADC10062 and ADC10064 sample the an-

alog input voltage once every conversion cycle When this

happens the input is briefly connected to an impedance

approximately equal to 600X in series with 35 pF Short-du-

ration current spikes can therefore be observed at the ana-

log input during normal operation These spikes are normal

and do not degrade the converter’s performance

Large source impedances can slow the charging of the

sampling capacitors and degrade conversion accuracy

Therefore only signal sources with output impedances less

than 500X should be used if rated accuracy is to be

achieved at the minimum sample time (250 ns maximum) If

the sampling time is increased the source impedance can

be larger If a signal source has a high output impedance its

output should be buffered with an operational amplifier The

operational amplifier’s output should be well-behaved when

driving a switched 35 pF 600X load Any ringing or voltage

shifts at the op amp’s output during the sampling period can

result in conversion errors

Correct conversion results will be obtained for input volt-

ages greater than GND b 50 mV and less than V

a

a

50 mV Do not allow the signal source to drive the analog

input pin more than 300 mV higher than AV

CC

and DV

CC

or

more than 300 mV lower than GND If an analog input pin is

forced beyond these voltages the current flowing through

the pin should be limited to 5 mA or less to avoid permanent

damage to the IC The sum of all the overdrive currents into

all pins must be less than 20 mA When the input signal is

expected to extend more than 300 mV beyond the power

supply limits some sourt of protection scheme should be

used A simple network using diodes and resistors is shown

in

Figure 4

11