Chip information, Package information, Table 1. recommended inductors – Rainbow Electronics MAX8815A User Manual

Page 12

MAX8815A

1A, 97% Efficiency, 30µA Quiescent Current

Step-Up Converter with True Shutdown

Inductor Selection

In most step-up converter designs, a reasonable induc-

tor value can be derived from the following equation.

This equation sets peak-to-peak inductor current at 1/2

the DC inductor current:

L = (2 x V

BATT

x D x (1 - D))/(I

OUT(MAX)

x f

SW

)

where f

SW

is the switching frequency (2MHz), and D is

the duty factor given by D = 1 - (V

BATT

/V

OUT

). Using L

from the equation above results in a peak-to-peak

inductor current ripple of 0.5 x I

OUT

/(1 - D), and a peak

inductor current of 1.25 x I

OUT

/(1 - D). Ensure that the

peak (saturation) current rating of the inductor meets or

exceeds this requirement. The recommended induc-

tance range for the MAX8815A is 1µH to 2.2µH. See

Table 1 for recommended inductors.

Capacitor Selection

Output Capacitor

Output capacitor C2 in Figures 1a and 1b is required to

keep the output voltage ripple small and to ensure reg-

ulation loop stability. The output capacitors must have

low impedance at the switching frequency. Make sure

the output capacitors maintain their capacitance over

DC bias and the desired operating temperature range.

One 22µF tantalum capacitor is recommended.

Input Capacitor

Input capacitor C1 reduces the current peaks drawn

from the battery or input power source and reduce

switching noise in the IC. The impedance of the input

capacitor at the switching frequency should be kept

very low. A ceramic capacitor is highly recommended

due to their small size and low ESR. Make sure the

input capacitors maintain their capacitance over DC

bias and the desired operating temperature range.

Ceramic capacitors with X5R or X7R dielectric temper-

ature characteristics generally perform well. Two 4.7µF

or one 10µF ceramic capacitors are recommended.

PCB Layout and Routing

Good printed-circuit board (PCB) layout is important to

achieve optimal performance for the MAX8815A. Poor

design can cause excessive conducted and radiated

noise. Conductors carrying discontinuous currents and

any high-current path should be made as short and

wide as possible. Keep the feedback network (R1 and

R2) very close to the IC, preferably within 0.2in of the

FB and GND pins. Nodes with high dV/dt (switching

nodes) should be kept as small as possible and routed

away from FB. Connect the input and output capacitors

as close as possible to the IC. Refer to the MAX8815A

EV kit data sheet for a PCB layout example.

Chip Information

PROCESS: BiCMOS

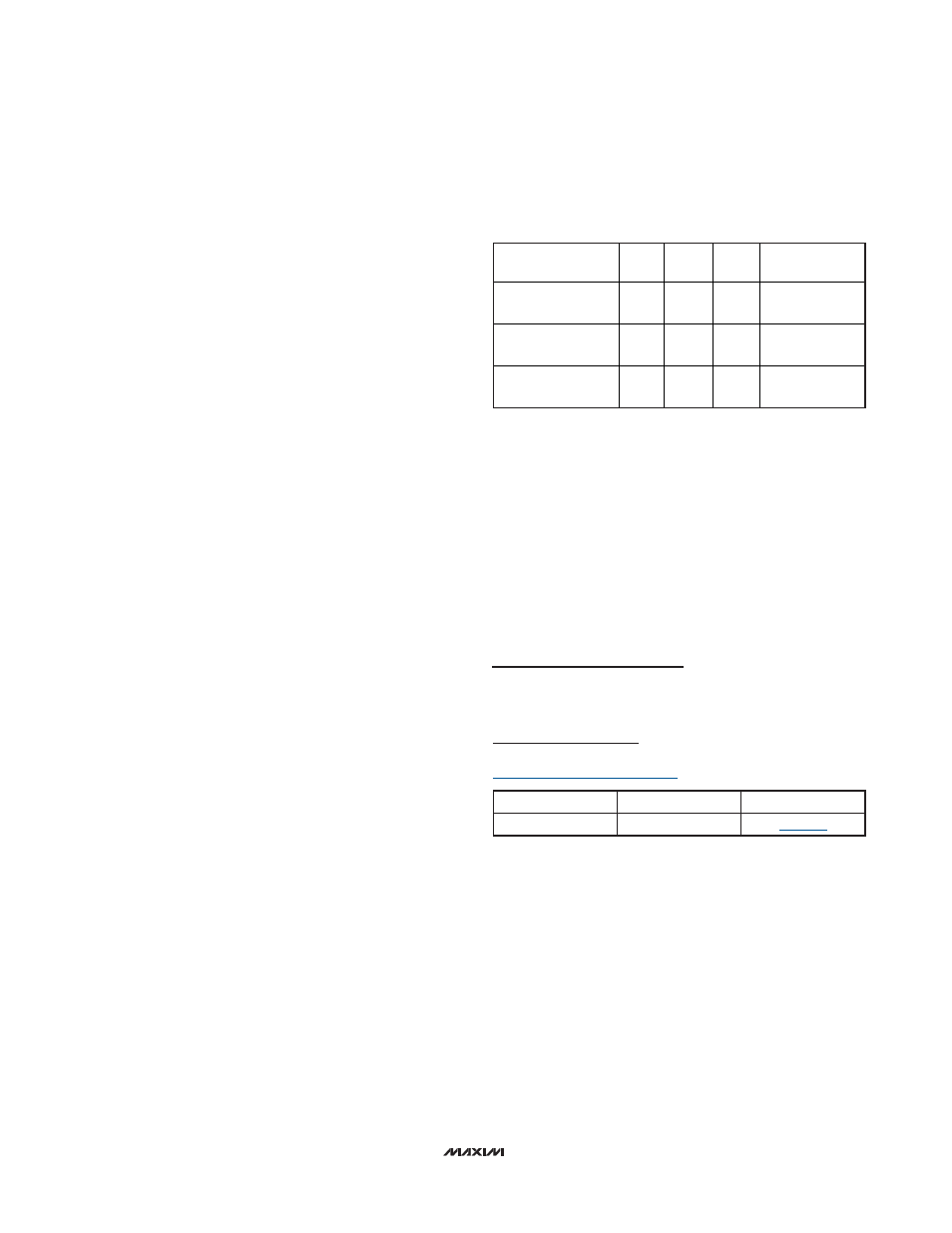

INDUCTOR

L

(µH)

DCR

(m

Ω)

I

SAT

(A)

SIZE (mm)

TOKO DE4012CK

A1101AS-1R0M

1

45

3.3

4 x 4 x 1.2

TOKO DE4012CK

A1101AS-2R2M

2.2

60

2.8

4 x 4 x 1.2

TOKO 2818C

1072AS-1R0M

1

40

2.8

2.8 x 2.8 x 1.8

Table 1. Recommended Inductors

PACKAGE TYPE

PACKAGE CODE

DOCUMENT NO.

10 TDFN-EP

T1033-2

Package Information

For the latest package outline information, go to

www.maxim-ic.com/packages

.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products

is a registered trademark of Maxim Integrated Products, Inc.