Model 6700 downflow, Service instructions (cont’d.), Page 28 – Peerless Water 6700 - Service Manual User Manual

Page 28

Printed in U.S.A.

Page 28

MODEL 6700 Downflow

Service Instructions (Cont’d.)

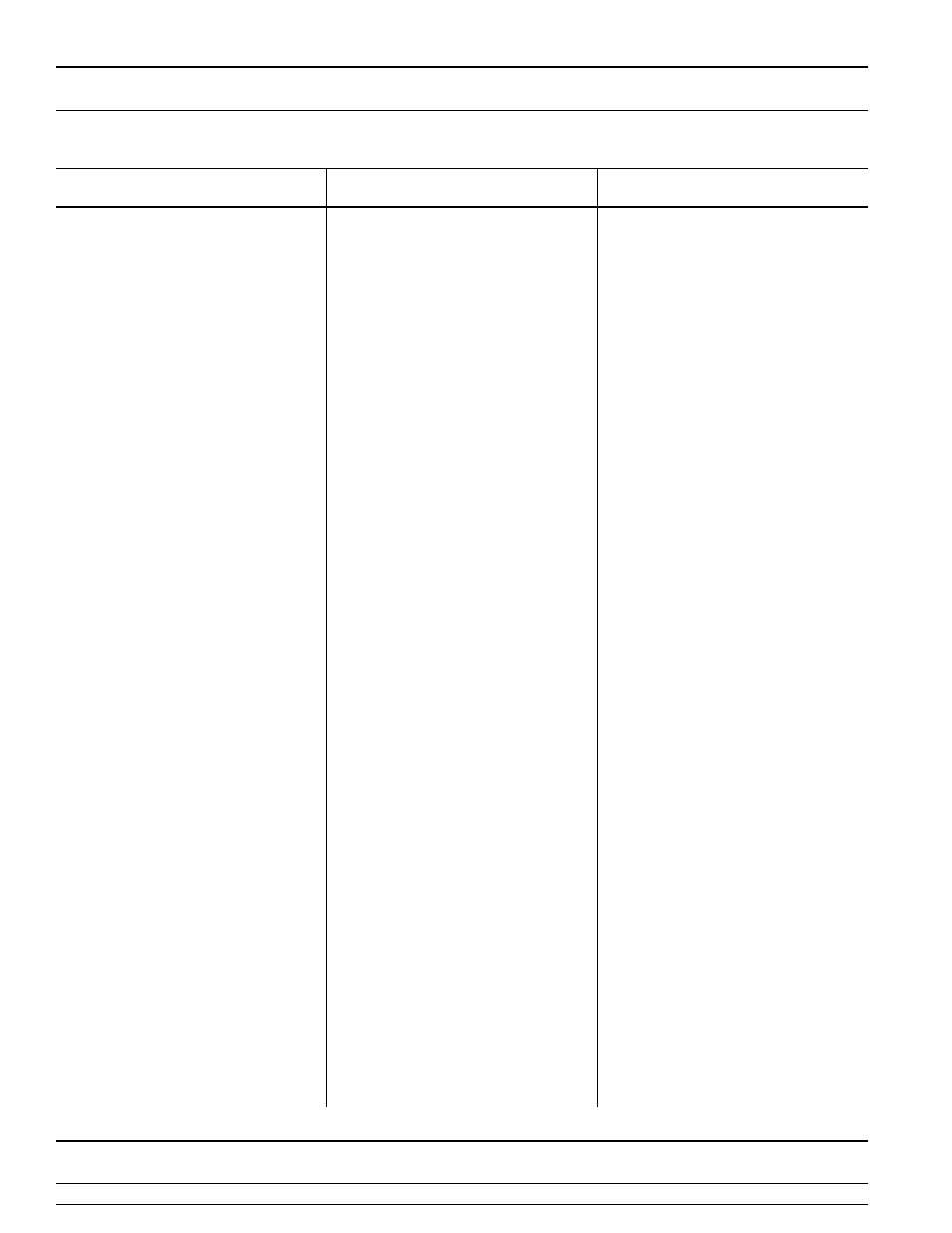

6.

Iron in conditioned water.

A.

Fouled resin bed.

B.

Iron content exceeds

recommended parameters.

A.

Check backwash, brine draw and

brine tank fill. Increase frequency

of regeneration. Increase back-

wash time.

B.

Add iron removal from filter or

system.

7.

Excessive water in brine tank.

A.

Plugged drain line flow control.

B.

Brine valve failure.

C.

Improper programming.

A.

Clean flow control.

B.

Replace brine valve.

C.

Check programming and reset as

needed.

8.

Salt water in service line.

A.

Plugged injector system.

B.

Timer not operating properly.

C.

Foreign material in brine valve.

D.

Foreign material in brine line flow

control.

E.

Low water pressure.

F.

Improper programming.

A.

Clean injector and replace

screen.

B.

Replace timer.

C.

Clean or replace brine valve.

D.

Clean brine line flow control.

E.

Raise water pressure.

F.

Check programming and reset as

needed.

9.

Softener fails to draw brine.

A.

Drain line flow control is plugged.

B.

Injector is plugged.

C.

Injector screen plugged.

D.

Line pressure is too low.

E.

Internal control leak.

F.

Improper programming.

G. Timer not operating properly.

A.

Clean drain line flow control.

B.

Clean or replace injectors.

C.

Replace screen.

D.

Increase line pressure. (Line

pressure must be at least 25 psi

at all times.)

E.

Change seals and spacers and/or

piston assembly.

F.

Check programming and reset as

needed.

G. Replace timer.

10. Control cycles continuously.

A.

Timer not operating properly.

B.

Faulty microswitches and or

harness.

C.

Faulty cycle cam operation.

A.

Replace timer.

B.

Replace faulty microswitch or

harness.

C.

Replace cycle cam or reinstall.

11. Drain flows continuously.

A.

Foreign material in control.

B.

Internal control leak.

C.

Control valve jammed in brine or

backwash position.

D.

Timer motor stopped or jammed.

E.

Timer not operating properly.

F.

Faulty cycle cam operation.

G. Faulty microswitches and/or

harness.

A.

Remove Piston assembly and

inspect bore, remove foreign

material & check control in various

regeneration positions.

B.

Replace seals and/or piston

assembly.

C.

Replace piston and seals and

spacers.

D.

Replace timer, motor and check

all gears for missing teeth.

E.

Replace timer.

F.

Replace cycle cam or reinstall.

G. Replace faulty microswitches and/

or harness.

PROBLEM

CAUSE

CORRECTION