Assembly instructions (continued) – Wilwood Dynapro Lug Mount Rear Parking Brake Kit User Manual

Page 6

Assembly Instructions (Continued)

Page 6

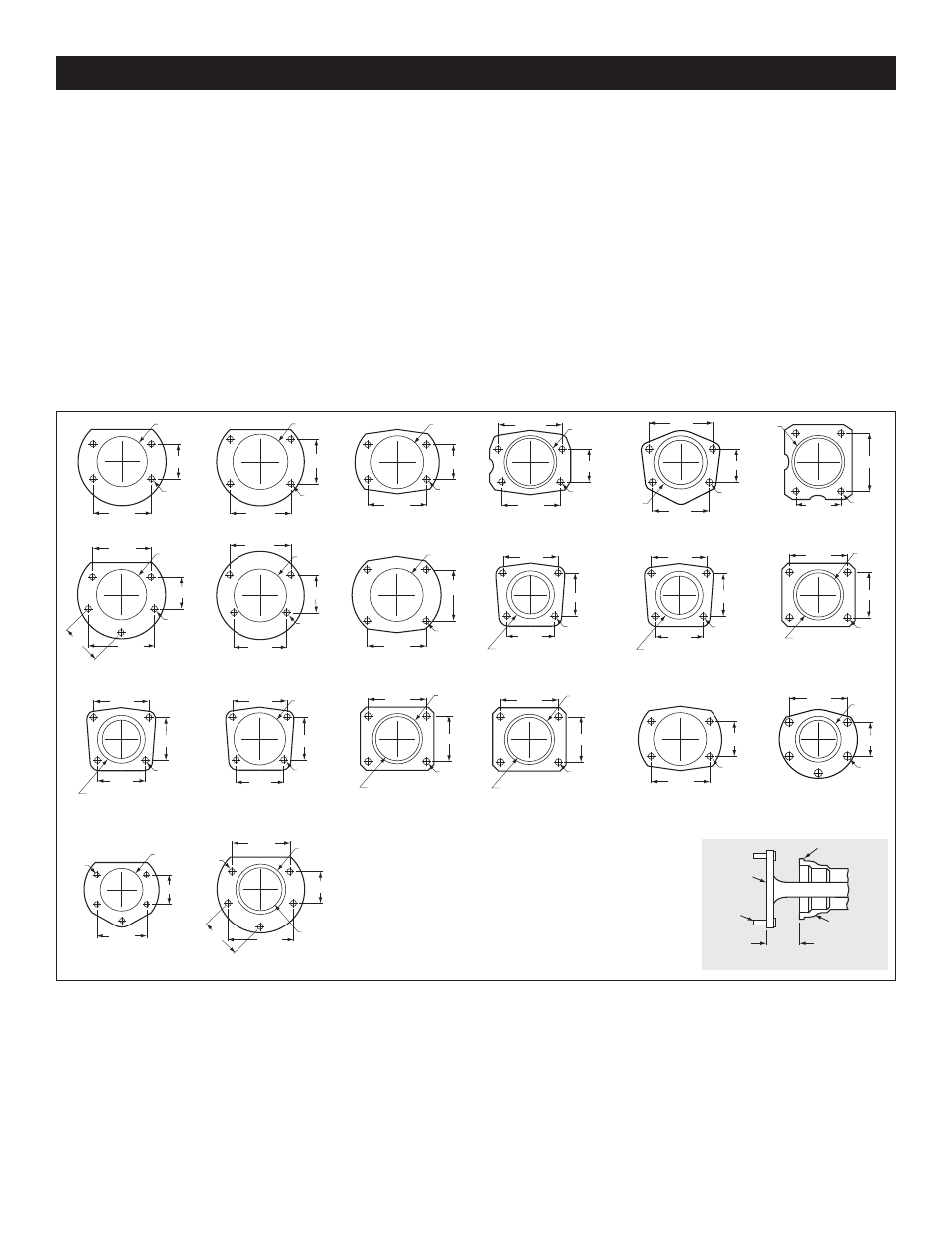

Figure 6. Rear Housing Flange Chart and Axle Flange / Offset Cross-Section

2.000

2.835 DIA

3/8”

BOLT

3.336

SMALL FORD

2.375

3.150 DIA

1/2”

BOLT

3.500

BIG FORD

2.000

3.150 DIA

3/8”

BOLT

3.562

BIG FORD (NEW STYLE)

3/8”

BOLT

2.000

3.562

SPEEDWAY

ENGINEERING

MODLITE

3/8”

BOLT

1.680

TUBING O.D.

2.840

3.076

3.410

8.8" FORD

8-3/4 AND 9-3/4

MOPAR / DANA 60

3/8”

BOLT

1.594

2.875 DIA

3.562

2.203

3.188

2.000

2.560

DIA

3.336

AMC

3/8”

BOLT

3/8”

BOLT

DANA 35

1.594

2.875

DIA

TUBING O.D.

2.600 - 2.875

3.562

2.203

3.188

OLDS

PONTIAC

3/8”

BOLT

2.375

3.150 DIA

2.875

3.500

CHEVY

(SPECIAL)

3/8”

BOLT

3.150

DIA

2.404

2.652

3.072

3/8”

BOLT

10 / 12 BOLT

CHEVY

2.404

2.652

3.072

TUBING O.D. 2.725

3/8”

BOLT

12 BOLT CHEVY

C-CLIP ELIMINATOR

2.404

2.652

3.072

TUBING O.D. 2.725

3/8”

BOLT

MARK

WILLIAMS

3.000

3.150 DIA

3.000

3/8”

BOLT

MUSTANG (05-UP)

3.746

TUBING O.D.

3.190

2.304

AXLE FLANGE CROSS-SECTION

AXLE OFFSET

AXLE

AXLE HOUSING

FLANGE

AXLE TUBE

AXLE

FLANGE

WHEEL

STUD

TUBING

O.D. 3.420

1955-1957 CHEVY

1956 CORVETTE

2.656

3.396

2.835 DIA (1955/56)

3.000 DIA (1957)

3/8” BOLT

3/8”

BOLT

2.404

2.652

3.072

TUBING O.D. 2.840

12 BOLT-LATE

CHEVY

TUBING

O.D. 3.420

1957-1962 CORVETTE

1959-1964 IMPALA

2.656

3.396

3.000 DIA

3/8”

BOLT

3/8”

BOLT

2.531

DIA

CHEVY

C10

2.656

3.396

TUBING O.D.

3.420

3/8”

BOLT

STRANGE

ENGINEERING

FLOATER AXLE

1.750

2.373

DIA

3.030

3/8”

BOLT

TUBING

O.D. 2.685

2.87

7-1/4” FORD

3.23

1.680