Wilwood Tandem Master Cylinder User Manual

Page 2

Wilwood • Phone 805 / 388-1188

Fax 805 / 388-4938 • www.wilwood.com

E-mail Technical Assistance: [email protected]

Tandem Master Cylinders, Components and Accessories

Part No.

Description

260-4893

1-1/16" Bore Tandem Outlet Master Cylinder only

260-4894

1-1/16" Bore Tandem Outlet Master Cylinder with push rod, retainer, and boot

260-4896

1-1/16" Bore Master Cylinder Rebuild Kit

260-1874

2 Pound Residual Pressure Valve

260-1875

10 Pound Residual Pressure Valve

260-8419

Knob Adjustable Proportioning Valve

260-8420

Lever Adjustable Proportioning Valve

250-2406

Firewall Mount Reinforcement Plate

250-3677

Wilwood Pedal Adapter Plate Kit

340-1289

Floor Mount Pedal, 6:1 ratio

340-1290

Forward Swing Mount Pedal, 7:1 ratio

290-0632

Wilwood Hi-Temp 570 DOT 3 Fluid

290-6209

Wilwood EXP 600 Plus Super Hi-Temp Fluid

CALCULATING EFFECTIVE PISTON BORE AREA TO DETERMINE PLUMBING

To determine the effective piston bore area of any caliper, you must first calculate the area for each piston bore found on one side

of the caliper. Use the formula " Area = ( bore x bore) x .785" for each piston bore size. Then, add the areas of all pistons on that

one side of the caliper to determine the total effective piston bore area. Compare the difference between the front and rear calipers

and attach the line from the primary outlet "A" to the calipers at the end of the vehicle with the greater total effective piston bore area.

•

Connect the primary outlet port "A" to the brakes at the end of the vehicle with the greatest total effective piston bore area. On most vehicles,

this will be the front brake line (see note below).

•

Connect the secondary outlet port "B" to the brakes at the end of the vehicle with the lesser total effective piston bore area. On most vehicles, this

will be the rear brake line (see note below).

•

On disc brake applications, where the fluid

reservoir is mounted higher than the

caliper bleeds, a residual pressure valve is

usually not required.

•

On disc brake applications, where the fluid

reservoir is mounted lower than the caliper

bleeds, may require a 2 pound residual

pressure valve to prevent fluid drain back

and excessive pedal travel.

•

All drum brake applications require an

inline 10 pound residual pressure valve.

•

Use an adjustable proportioning valve to

set the front to rear brake bias.

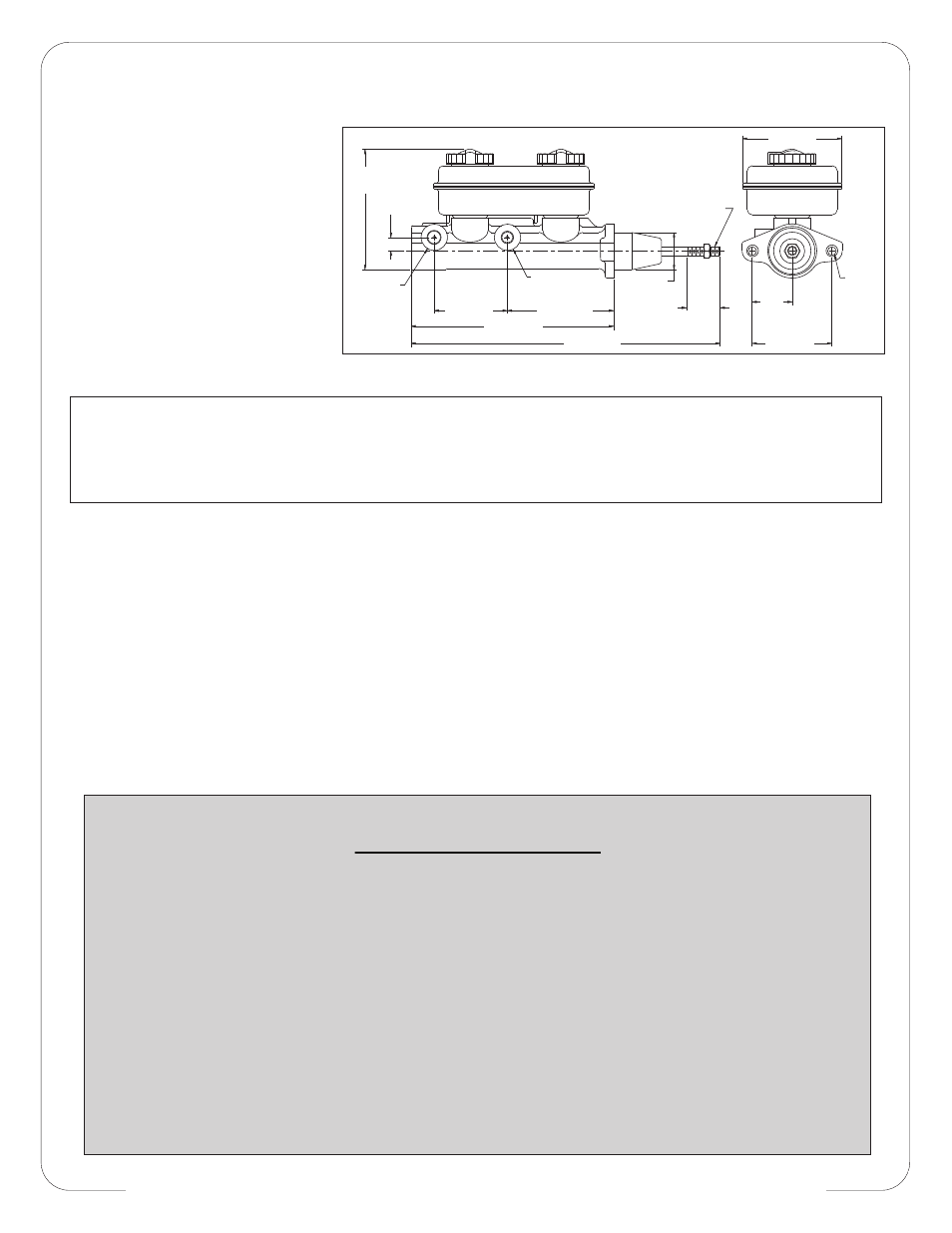

.34 (8,6)

DIA

MOUNT

HOLE

3/8-24 THREAD

1.50 (38,1)

DIA

1/2-20 THREAD

INVERTED FLARE

OUTLET "A"

9/16-20 THD

INVERTED

FLARE

OUTLET "B"

3.61 (91,7)

4.27 (108,5)

2.94 (74,7)

8.14 (206,8)

12.42 (315,5)

4.83

(122,7)

.55

(14,0)

1.35

(34,3)

STROKE

1.60

(40,6)

3.20 (81,3)

Tandem Master Cylinder, Mounting Dimensions

• Make sure pedal is firm: Hold firm pressure on pedal for several minutes, it should remain in position without

sinking. If pedal sinks toward floor, check system for fluid leaks. DO NOT drive vehicle if pedal does not stay firm

or can be pushed to the floor with normal pressure.

• At very low speed (2-5 mph) apply brakes hard several times while turning steering from full left to full right, repeat

several times. Remove the wheels and check that components are not touching, rubbing, or leaking.

• Carefully examine all brake components, brake lines, and fittings for leaks and interference.

• Make sure there is no interference with wheels or suspension components.

• Drive vehicle at low speed (15-20 mph) making moderate and hard stops. Brakes should feel normal and

positive. Again check for leaks and interference.

• Always test vehicle in a safe place where there is no danger to (or from) other people or vehicles.

• Always wear seat belts and make use of all safety equipment.

WARNING • DO NOT DRIVE ON UNTESTED BRAKES

BRAKES MUST BE TESTED AFTER INSTALLATION OR MAINTENANCE

MINIMUM TEST PROCEDURE