Wilwood Tandem Master Cylinder User Manual

Aluminum tandem master cylinder

4700 Calle Bolero • Camarillo, CA 93012

Phone 805 / 388-1188 • Fax 805 / 388-4938

Installation Notes and Precautions

•

Always mount the master cylinder to a secure, reinforced element of the chassis. There should be no movement or deflection at the mount

point when brake pedal pressure is applied. When using fabricated mounts or pedal linkages, it is important that the alignment of the push

rod and piston are kept as straight as possible to prevent side loading the piston against the master cylinder bore

•

Be sure the pedal and push rod are adjusted to allow the master cylinder piston to fully retract against the snap ring at the back of the master

cylinder bore when the pedal is fully retracted. There should also be adequate pedal travel to fully compress the master cylinder. Pedal return

springs and stops are highly recommended.

•

Prior to attaching the fluid lines, fill the reservoirs with Wilwood fluid from a new, sealed container and purge any air from the master cylinder.

Be sure the cylinder is level during the bleeding operation. If the cylinder is not level when mounted in the vehicle, you can perform this

operation prior to attaching the master cylinder to its mount. The diagram illustrates one method of recycling the fluid into the reservoir until

all air has been eliminated. Exercise care to not spill or spray brake fluid. Take all proper safety precautions including eye and skin protection

and do not position your face directly above the

reservoir. This process will assure a quick and effective

full system bleed later.

•

Once all fluid connections have been made, the

complete system must be bled and checked for leaks

prior to any test of the vehicle.

Plumbing Notes and Precautions

•

Flare nuts to fabricate double flared 3/16" diameter

brake lines are included with each master cylinder. Use

only double flared lines. Do not attempt to use single

flared connections. Standard automotive double flared

lines with the correct size fittings can also be

purchased pre-made from an auto parts store.

•

Use of reinforced flexible lines should be limited to the

connection between the fixed chassis and the moving

suspension. All other lines along the fixed chassis

should be hard steel lines.

WARNING

THIS COMPONENT IS DESIGNED FOR USE IN CUSTOM BRAKE SYSTEMS ON PERFORMANCE, RACING, AND OTHER SPECIAL

PURPOSE BUILT OFF-ROAD VEHICLES. IT IS NOT INTENDED AS A DIRECT REPLACEMENT FOR ANY OEM APPLICATION.

DS-260E REV DATE; 06-29-09

ALUMINUM TANDEM MASTER CYLINDER

SPECIFICATION SHEET • INSTRUCTIONS

Master Cylinder Part Number: 260-4893

Master Cylinder Kit Part Number: 260-4894

Component

Specifications

Piston Bore Diameter

1-1/16 inches

Maximum Piston / Push Rod Travel

1.35 inches

Primary Piston Stroke: "A" Outlet

.90 inches

Secondary Piston Stroke: "B" Outlet

.45 inches

Primary Outlet Port "A"

1/2-20 inverted flare

Secondary Outlet Port "B"

9/16-20 inverted flare

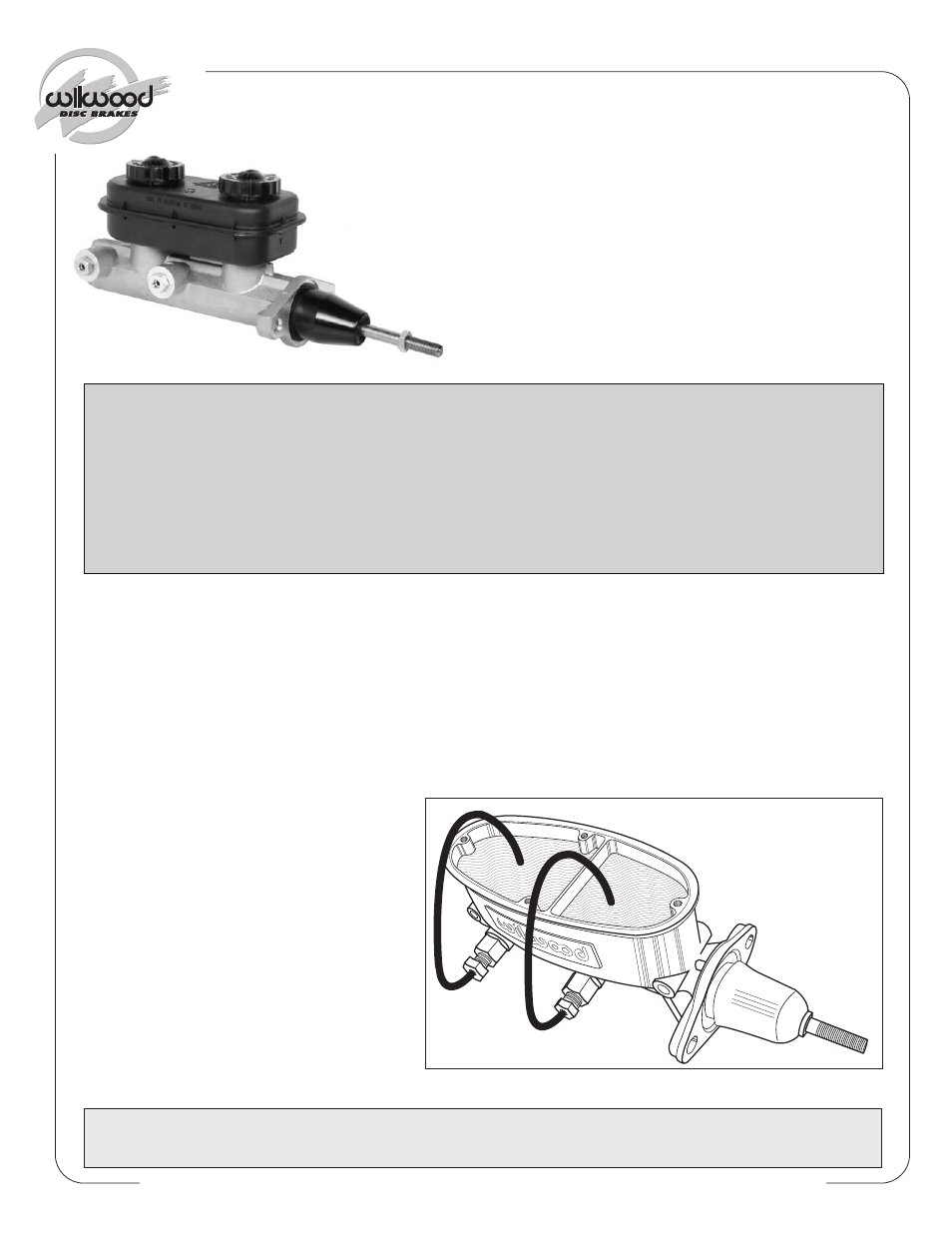

Typical Bleeder Tube Setup and Use

PRESS IN AND

RELEASE

SEVERAL TIMES

BLEEDER TUBES

WARNING

IT IS THE RESPONSIBILITY OF THE PERSON INSTALLING ANY BRAKE COMPONENT OR KIT TO DETERMINE THE SUITABILITY OF THE

COMPONENT OR KIT FOR THAT PARTICULAR APPLICATION. IF YOU ARE NOT SURE HOW TO SAFELY USE THIS BRAKE COMPONENT OR

KIT, YOU SHOULD NOT INSTALL OR USE IT. DO NOT ASSUME ANYTHING. IMPROPERLY INSTALLED OR MAINTAINED BRAKES ARE

DANGEROUS. IF YOU ARE NOT SURE, GET HELP OR RETURN THE PRODUCT. YOU MAY OBTAIN ADDITIONAL INFORMATION AND

TECHNICAL SUPPORT BY CALLING WILWOOD AT (805) 388-1188, OR VISIT OUR WEB SITE AT WWW.WILWOOD.COM. USE OF WILWOOD

TECHNICAL SUPPORT DOES NOT GUARANTEE PROPER INSTALLATION. YOU, OR THE PERSON WHO DOES THE INSTALLATION MUST

KNOW HOW TO PROPERLY USE THIS PRODUCT. IT IS NOT POSSIBLE OVER THE PHONE TO UNDERSTAND OR FORESEE ALL THE ISSUES

THAT MIGHT ARISE IN YOUR INSTALLATION.

RACING EQUIPMENT AND BRAKES MUST BE MAINTAINED AND SHOULD BE CHECKED REGULARLY FOR FATIGUE, DAMAGE, AND WEAR.