Wilwood D8-4 Caliper Rear User Manual

Caliper highlights

4700 Calle Bolero

•

Camarillo, CA 93012

•

www.wilwood.com

•

Sales: (805) 388-1188

•

E-mail Tech Assistance:

213 REV DATE: 06-14-12

FORGED BILLET ALUMINUM D8

CORVETTE REPLACEMENT CALIPERS*

*Wheel clearance issues exist with the OE 1965-66 steel 15 x 5.50” wheels and some alloy replicas including K-H style knock-off wheels. Due to variations in

the production tolerance on all wheels, calipers, and caliper mounting brackets, always check for wheel clearance during installation. Should interference exist,

use a minimum thickness wheel spacer to provide adequate clearance.

Caliper Highlights:

D8 calipers are a direct bolt-on replacement for the factory original

calipers on all 1965-82 Chevrolet Corvettes. Forged billet aluminum

bodies, stainless steel pistons, and competition style high-temperature

seals put an end to the rust, bore pitting, and seal failures that plague

the OE cast iron caliper design. D8 calipers provide low-maintenance

performance and reliability for the Sunday afternoon driver, with a huge

weight savings and high temperature durability for the tracks.

D8 calipers mount in the stock location over stock rotors, and use the

original type D8 brake pads. They fit snugly inside any 1967 and later year

production steel rally wheel, as well as most of the later year optional alloy wheels.

Other wheels, including the 1965-66 production steel 5.50” wide “JK” production code

wheels and some aftermarket alloy replica wheels, will require a 3/16” or thicker wheel spacer for

clearance. The piston volumes of the

and

have both been matched to the original caliper piston

volumes to maintain the original front to rear brake bias and full compatibility with the output of the OE master cylinder.

Only the flex lines that connect the caliper to the hard line fittings on the chassis need to be replaced to install the D8-4 on

any car.

D8 forged billet aluminum caliper bodies are the product of Wilwood’s in-house FEA design and 3-D modeling technology. With its unyielding

strength and superior piston design, the D8-4 and D8-6 calipers generate positive pedal response and high clamping efficiency with a

substantial weight savings over the OE calipers. As compared to the individual weight of 13.2 pounds each for the OE calipers, a full set of

D8-4 calipers reduces unsprung suspension weight by 29 pounds.

Every D8 caliper is assembled with stainless steel pistons for corrosion resistance and to delay the heat transfer from the pad into the caliper

body, fluid and seals. The aluminum body itself provides cooler running temperatures through faster heat dissipation. Cooler operating

temperatures translate into longer service life for road or track. For extreme and sustained high temperature competition, D8 calipers can also

be custom built with Wilwood’s exclusive Thermlock pistons for the ultimate in thermal protection and reliability. To round out the package, the

calipers are fitted with our stainless steel SRS bridge wear plates to dampen noise and prevent excessive wear from pad gouging at the

caliper bridge.

D8 calipers can be run with any OE replacement pad, or optimized for street or track with one of

Three caliper finishes, including clear anodized on the base model, and optional gloss red or black powder coat are available to match the

personal preference and style for all types of applications.

D8-4 FRONT CALIPER ORDERING INFORMATION:

D8-4 REAR CALIPER ORDERING INFORMATION:

CLEAR ANODIZED BLACK RED

BORE SIZE

DISC WIDTH

PART NUMBER

PART NUMBER

PART NUMBER

1.88” 47,8 mm

1.25”

31,8 mm

D8-6 FRONT CALIPER ORDERING INFORMATION:

CLEAR ANODIZED BLACK RED

BORE SIZE

DISC WIDTH

P/N (R/L)

P/N (R/L)

P/N (R/L)

1.88/1.38/1.25”

1.25”

31,8 mm

CLEAR ANODIZED BLACK RED

BORE SIZE

DISC WIDTH

PART NUMBER

PART NUMBER

PART NUMBER

1.38” 35,1 mm

1.25”

31,8 mm

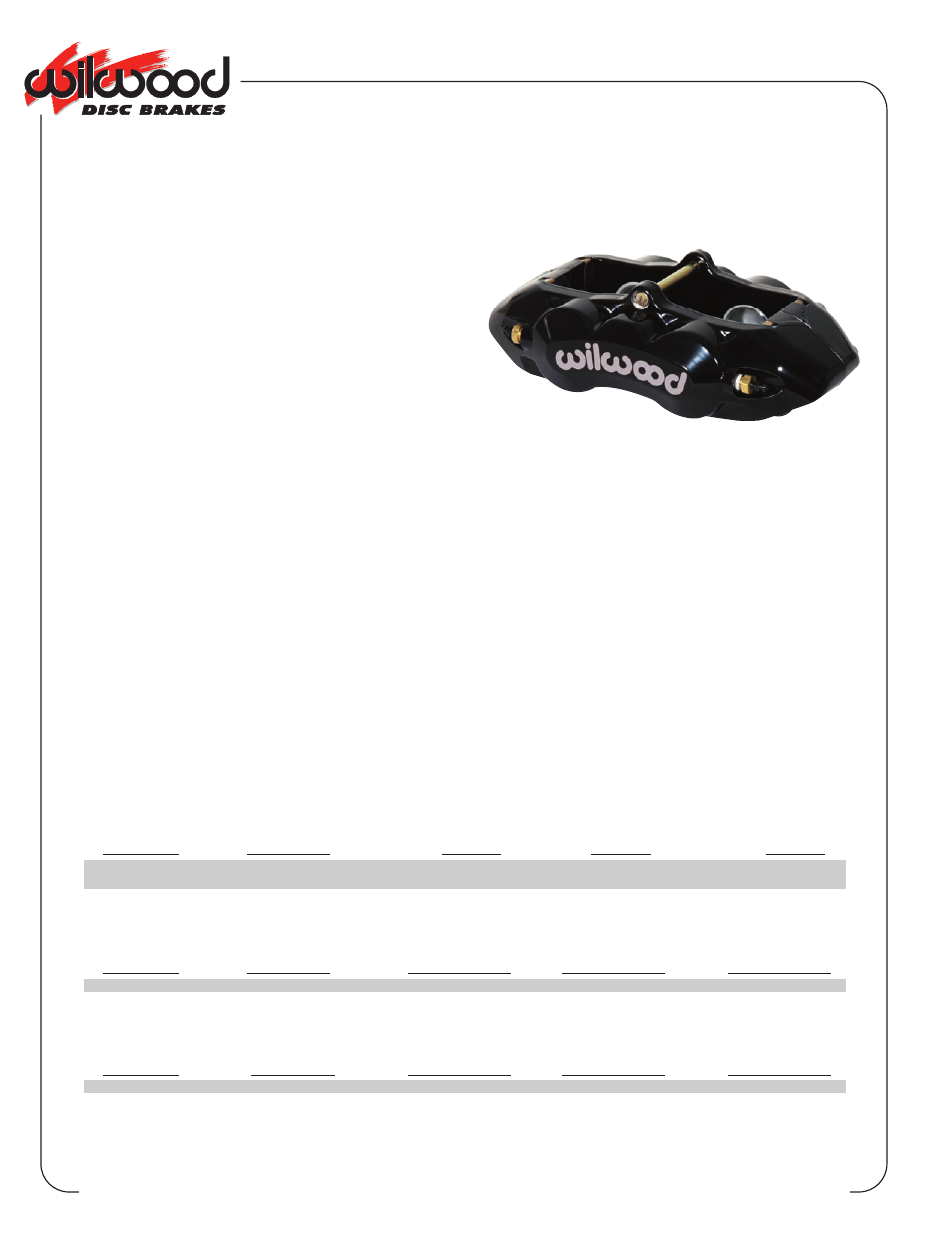

D8-4 Front Caliper Shown in

Black Powder Coat Finish