Assembly instructions – Wilwood Forged Dynalite Front Drag Brake Kit User Manual

Page 5

Assembly Instructions

Assembly Instructions (numbers in parenthesis refer to the part list/diagram on page 4): CAUTION: All mounting bolts must fully engage

insert nuts. Be sure to check that all bolts are either flush or protruding through flanged side of insert nut after shimming.

•As mentioned before, this kit uses the same mounting bracket (1) for both the drum and

disc brake spindle. The drum version utilizes four mounting bolts (designated with a “A”),

while the disc only requires three (designated with a “B”). Refer to figure 1 and figure 2

as required for the basic installation position of the bracket and the “A” and “B” reference

designations (these designations are not physically marked on the bracket, they are

referenced on the drawings for your convenience) and align using the three or four holes

(as applicable) to the face plate of the steering arm. Install bolts (2A or 2B) through

caliper mounting bracket (1) into steering arm, finger tighten only. After you are positive

of the bracket (1) alignment, remove the mounting bolts (2A or 2B) one at a time and

Apply red Loctite® 271 to bolt threads (2A or 2B), then reinstall. Torque bolts (2A or 2B)

to 30 ft-lb. NOTE: Be sure the heads of the bracket (1) insert nuts are facing outward

toward the wheel.

•Install wheel studs (3) into the hub (4). Torque to 77 ft-lb. NOTE: There are two (2) five

lug patterns in the hub (5 x 4.50 and 5 x 4.75). Make sure of the correct hole pattern for

the correct wheel application before installing studs into hub.

•Pack the large inner bearing cone (5) with high temperature disc brake bearing grease

(available from your local auto parts store) and install into the backside of the hub (4).

•Install the grease seal (6) by pressing into the backside of the hub (4).

•Attach rotor adapter plate (7) to rotor (8) using bolts (9). Using an alternating sequence,

apply red Loctite® 271 to the threads and torque bolts to 25 ft-lb. For an added measure

of security, the bolts may be safety wired using standard 0.032 inch diameter stainless

steel safety wire as shown in Figure 4. Please refer to Wilwood’s data sheet DS-386

(available at

www.wilwood.com/Pdf/DataSheets/ds386.pdf

) for complete safety wire

installation instructions. NOTE: Dished side of adapter plate (7) should face hub (4).

The machined tab side of the iron rotor (8) should face the adapter plate (7).

•Mount the adapter/rotor assembly (7/8) to the hub (4) using bolts (10) (finger tight), as shown

in Figure 1. Using an alternating sequence, remove bolts one at a time, apply red Loctite® 271

to the threads, and torque to 55 ft-lb.

•Pack the small outer bearing cone (11) with high temperature disc brake bearing grease and

install into front of hub (4). Slide the hub/rotor assembly (4 and 8) with outer bearing cone (11)

onto the spindle. Secure using spindle washer (12), stock adjusting nut and nut locking device.

Adjust bearings per Original Equipment Manufacturer (OEM) specifications.

•Install the o-ring (13) and then the dust cap (14) onto the hub (4). Friction created by the

o-ring (13) on the dust cap (14) keeps it from unscrewing.

•NOTE: Please reference the caution statement at the beginning of the assembly instructions.

Mount the caliper (15) onto the caliper bracket (1) using washers (16) and bolts (17). Place two

spacer washers (19) between the caliper (15) and the caliper mounting bracket (1) before

sliding the mounting bolts (17) all the way into the caliper mounting bracket (1), finger tighten

only. View the rotor (8) through the top opening of the caliper (15). The rotor (8) should be aligned in the center of the caliper (15). If

not, adjust the caliper (15) by using 0.032 inch thick shims (18) placed between the caliper (15) and the caliper spacer washer (19).

Finger tighten and recheck alignment. Use as many shim washers (18) as necessary to achieve the correct alignment. Add as many

shim washers (18) as necessary to achieve the correct alignment. NOTE: The end of the bolt must be flush with or slightly protuding

from the head of the clinch nut. See Figure 5. Place spare shims (18) between washer and caliper mounting ear to achieve the

proper mounting fastener configuration. Always use the same amount of shims on both the top and bottom caliper mounting bolts

(17). Apply red Loctite® 271 to bolt threads (17) and torque to 40 ft-lb. Caliper mount bolts may be safety wired for additional security.

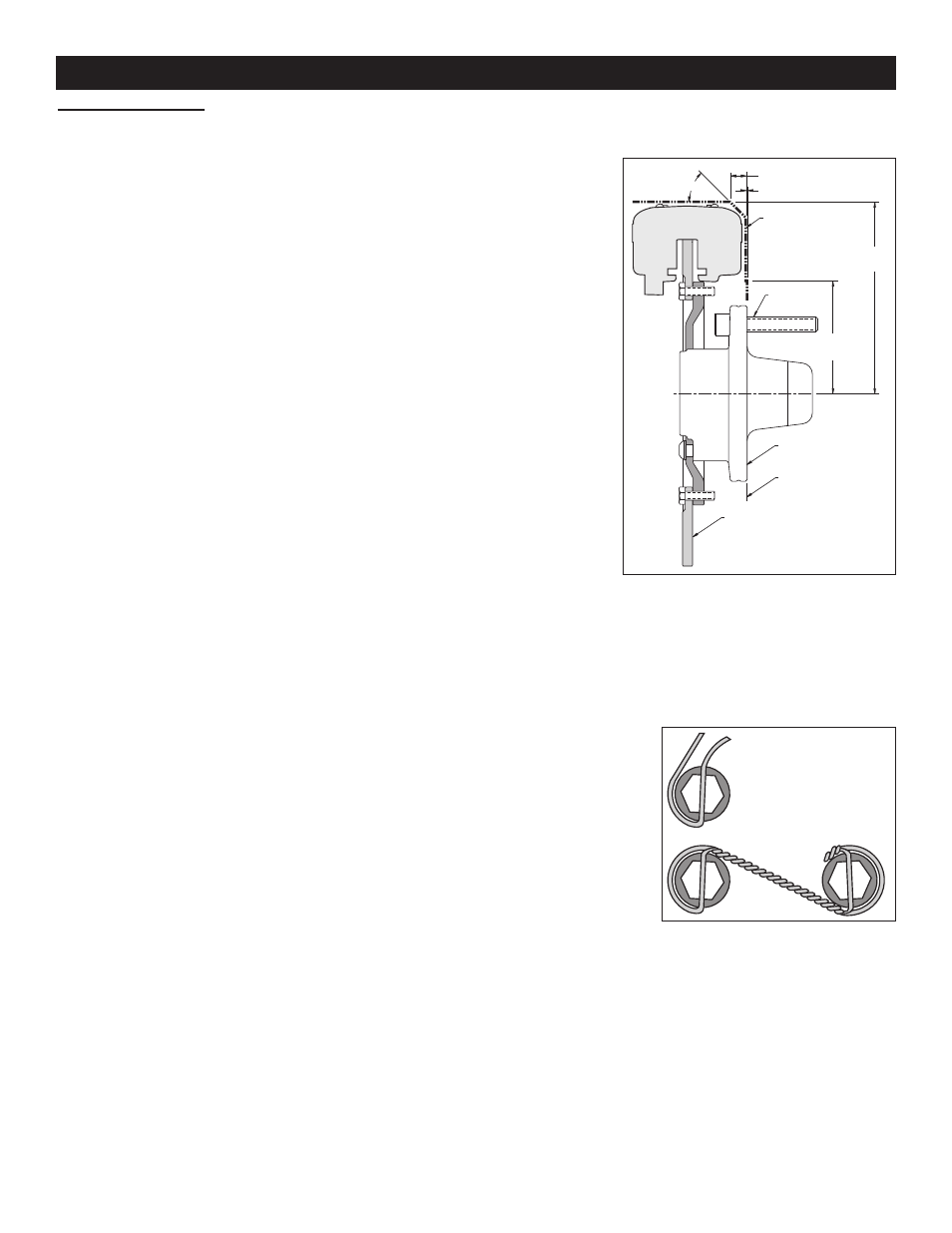

Figure 3. Wheel Clearance Diagram

BEGIN BY SLIDING THE 0.032"

DIAMETER WIRE THROUGH TWO OF

THE HOLES (LEFT) THAT ARE 180°

APART. TWIST THE WIRE AS

SHOWN (BELOW) USING SAFETY

WIRE PLIERS. NOW SLIDE ONE

WIRE THROUGH TWO OF THE

HOLES (180° APART) AND WRAP THE

OTHER WIRE AROUND THE BOLT.

TWIST THE WIRES TOGETHER TO

FORM A PIGTAIL. SEE DS-386 FOR

COMPLETE DETAILS.

Figure 4. Safety Wire Diagram

Page 5