Wilwood W6A Front Caliper and Bracket Upgrade Kit User Manual

Page 3

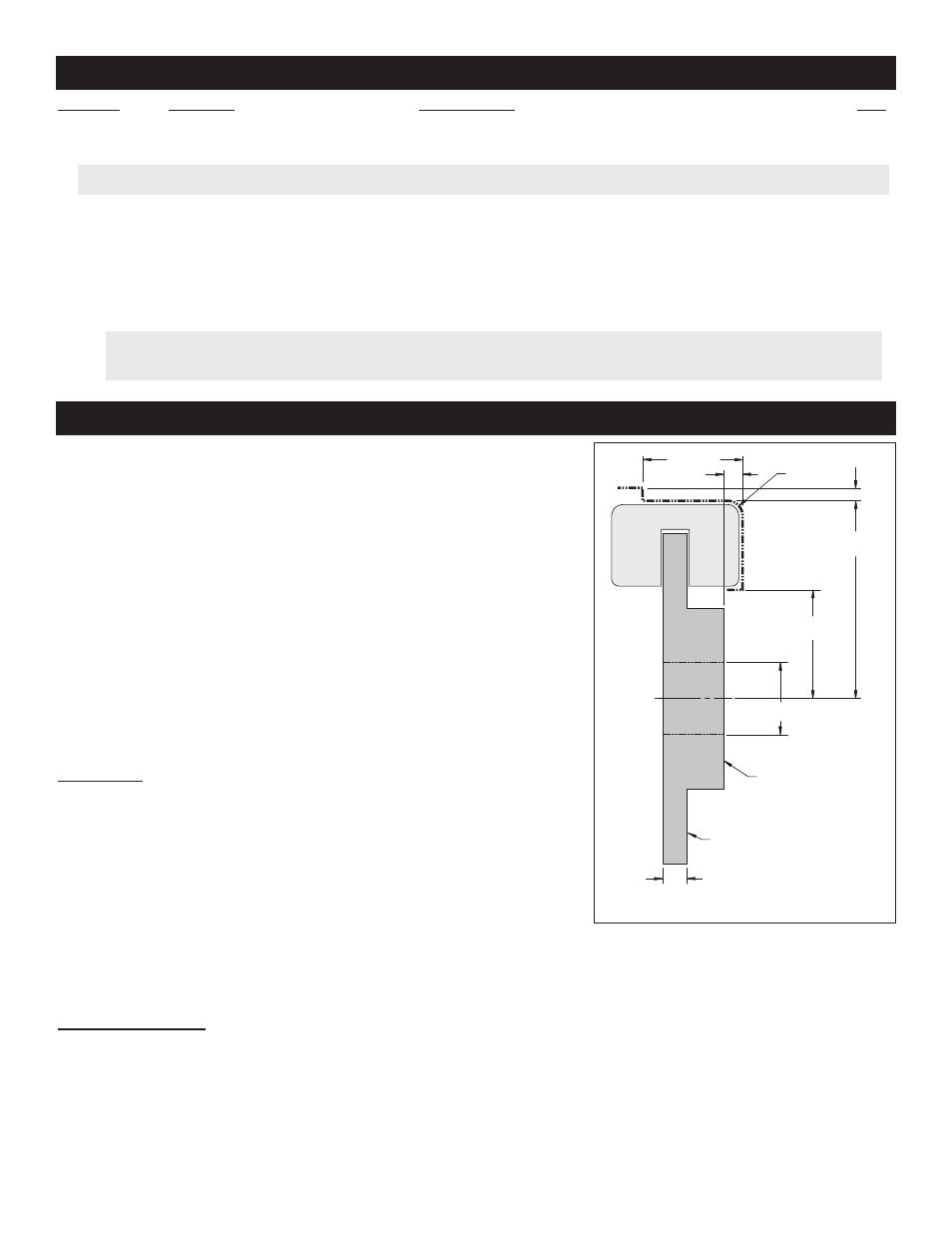

General Information, Disassembly and Assembly Instructions

Parts List

1

2

3

3A

3B

4

5

6

7

8

2

12

2

2

2

4

4

4

16

1

250-11721

240-8969

120-11663/64-RS

120-11663/64-RSN

120-11663/64-RSR

230-9182

240-11101

230-9080

240-3902

150-9489K

ITEM NO.

PART NO.

DESCRIPTION

QTY

NOTES: Part Number 250-11720 Caliper Mounting Bracket Kit, includes part numbers 250-11721, 230-9080, 230-9182, 240-3902, 240-11101,

240-8969 and 300-10827 (not used)

Wilwood offers an optional Braided Stainless Steel Hose Kit. Order part number 220-8176 (C-5) or 220-9100 (C-6) (not included in kit)

Item 3A is an optional item available in the “-N” nickel caliper kit. Add “-N” to end of part number when ordering.

Item 3B is an optional item available in the “-R” red caliper kit. Add “-R” to end of part number when ordering.

Page 3

- Aluminum Tandem M_C Kit with Bracket and Valve (1 page)

- Forged Dynalite Pro Series Front Brake Kit (9 pages)

- W4A Big Brake Rear Parking Brake Kit (9 pages)

- Brake & Clutch Pedal Description (3 pages)

- Brake & Clutch Pedal Description (4 pages)

- Brake & Clutch Pedal Description (5 pages)

- W6A Big Brake Front Brake Kit (Race) (7 pages)

- GP320 Sprint Left Front Brake Kit (6 pages)

- MasterCylinder No: 260-3501 (2 pages)

- Stealth Motorcycle Front Brake Kit (4 pages)

- Billet Superlite 6 Lug Mount Caliper (4 pages)

- MasterCylinder No: 260-9921 (1 page)

- Dynapro Dust-Boot Rear Parking Brake Kit (10 pages)

- W4A Big Brake Rear Brake Kit For OE Parking Brake (8 pages)

- SC1 Single Piston (1 page)

- Forged Narrow Superlite 4R Big Brake Rear Brake Kit For OE Parking Brake (8 pages)

- Dynapro Radial Front Drag Brake Kit (7 pages)

- Dynapro 6 Big Brake Front Brake Kit (Hub) (8 pages)

- Promatrix Front Replacement Rotor Kit (6 pages)

- D8-6 Front Replacement Caliper Kit (6 pages)

- Compact Remote Flange Mount Master Cylinder (6 pages)

- W4A Big Brake Front Brake Kit (Race) (7 pages)

- Forged Dynalite Front Drag Brake Kit (Hat) (8 pages)

- W4A Big Brake Truck Rear Brake Kit (7 pages)

- Dynapro Radial Big Brake Front Brake Kit (Hat) (7 pages)

- Narrow Dynapro Radial Mount (2 pages)

- Dynapro Dust-Boot Pro Series Front Brake Kit (9 pages)

- GM III Single Piston Floater (2 pages)

- Billet Superlite 4R Radial Mount (2 pages)

- Dynapro Dust-Boot Big Brake Front Brake Kit (Hub) (9 pages)

- High Volume Master Cylinder (2 pages)

- D52 Rear Caliper Kits (5 pages)

- Forged Narrow Superlite 6R Big Brake Front Brake Kit (Hat) (7 pages)

- Promatrix Front and Rear Replacement Rotor Kit (5 pages)

- Dynapro Single Front Drag Brake Kit (8 pages)

- Powerlite Radial Mount (2 pages)

- HI-TEMP Brake Fluid (1 page)

- Dynapro SA Lug Drive Dynamic Rear Drag Brake Kit (9 pages)

- MC4 Mechanical (1 page)

- W4A (2 pages)

- EXP600 PLUS Brake Fluid (1 page)

- D154 Front Caliper Kits (6 pages)

- 60 Degree Pedal Description (6 pages)

- Forged Dynalite Pro Series Rear Brake Kit (8 pages)

- Dynapro Dust-Boot (2 pages)