Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1187 User Manual

Page 23

18

Series 2 Incline Chain Conveyors

Options

PNEG-1187

Drill the four holes in the conveyor’s bottom to accom-

modate the 5/8" hardware provided. Attach the torque

arm bracket to the conveyor using four 5/8” hardware.

Under any circumstances, do not use the 3/8" bolts

previously removed from the conveyor bottom to

attach the torque arm to the conveyor.

Install shaft mount reducer to head shaft per instruc-

tions on page 14.

Next, match the size of the hardware to the reducer

manufacturer’s torque arm. Use this hardware to at-

tach the torque arm to the bracket. Adequately tighten

all hardware.

When a drive package is ordered with the conveyor

system, a torque arm bracket is provided.

The torque arm bracket is pre-punched for ease of in-

stallation to the unit. Begin installation of this option by

first determining the location of the torque arm bracket

relative to the range of extension allowed by the shaft

mount reducer’s torque arm. The bracket will extend

on the same side of the conveyor as the head shaft.

Remove the four bolts necessary from the bottom of

the conveyor plate.

Torque Arm Bracket

Installation

Standard Bypass Inlets

The Bypass Inlets come pre-assembled from the

factory. The inlets are available in 3' and 10'

sections. The hogback is stationary in bypass

inlets. Bypass inlets must be mounted horizontally.

If not mounted horizontally, capacity will be re-

duced.

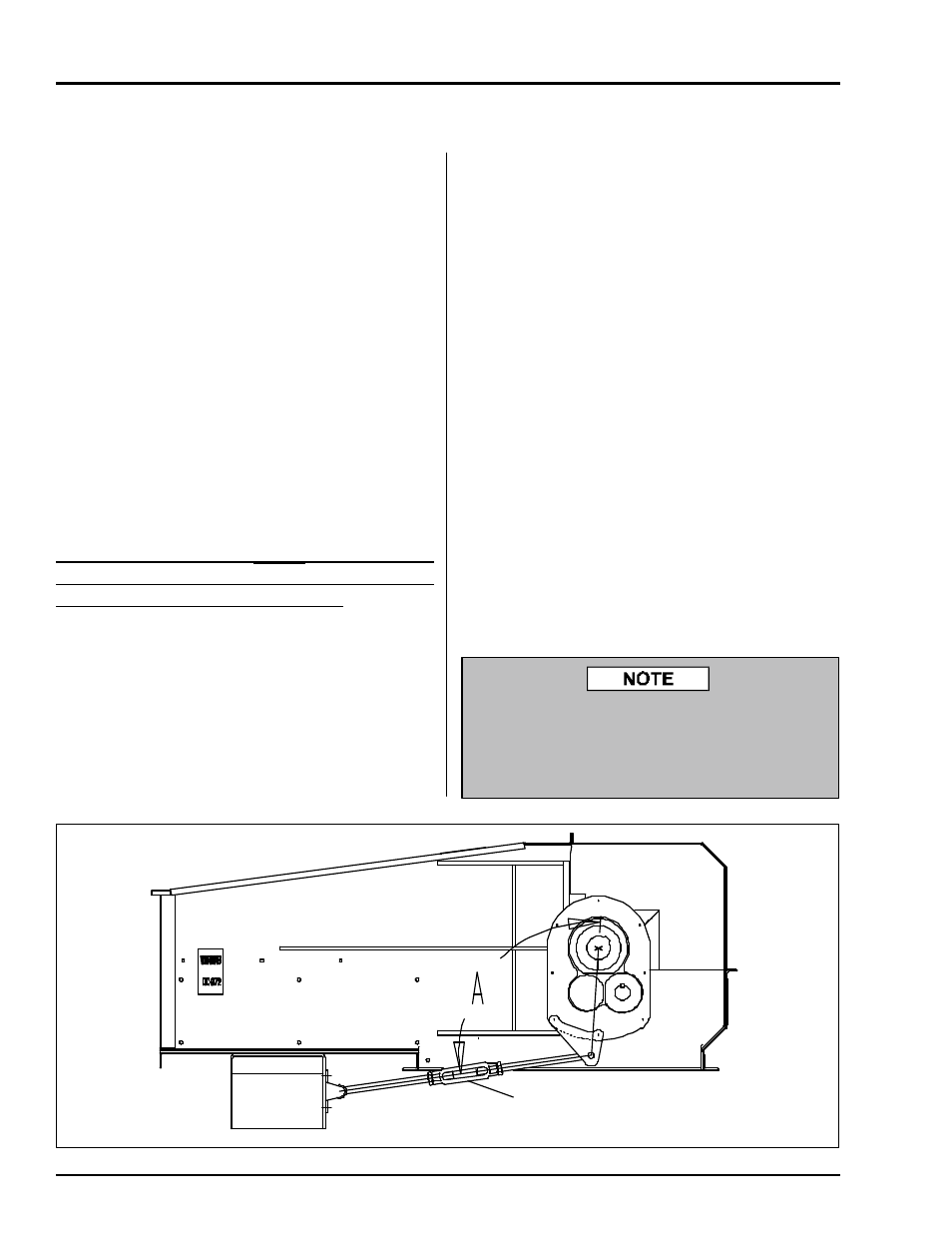

When installing torque arm bracket keep angle

(A) of torque arm and reducer between -15°

and +15° of 90° per manufacturer’s recommen-

dations. This angle is shown in Fig. 11.

Fig. 11

Torque Arm