Installation – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1187 User Manual

Page 17

12

Series 2 Incline Chain Conveyors

Installation

PNEG-1187

Before assembling conveyor trough sections together

remove covers. It is recommended that you store your

covers in a protected area in order to minimize any pos-

sible damage. Remember to retain factory shipped hard-

ware for conveyor cover installation.

Intermediate trough sections are supplied in standard

ten foot (10') lengths. Depending on your application

and individual specifications however, shorter sections

may be required to accommodate a given overall length.

During assembly of each trough section to the next sec-

tion, carefully inspect each flange joint to ensure that the

inside bottom and center pan/slide rail side surfaces of

the trough are flush. A chalk line is helpful during this

phase of the assembly to ensure the proper alignment of

the trough surfaces. The maximum run-out in any direc-

tion should be +/- 1/4". This proper alignment will mini-

mize wear on flights and other potential damage to the

conveyor. Make sure that the conveyor is level in hori-

zontal applications.

Proceed by attaching the head and tail assemblies using

the same alignment procedures and precautions noted in

the preceding paragraph.

Intermediate sections are supplied with slide rails or a

center pan. The sections with slide rails are generally

used on the horizontal portion of the conveyor. The

sections with the center pans are generally used on the

inclined portion of conveyor.

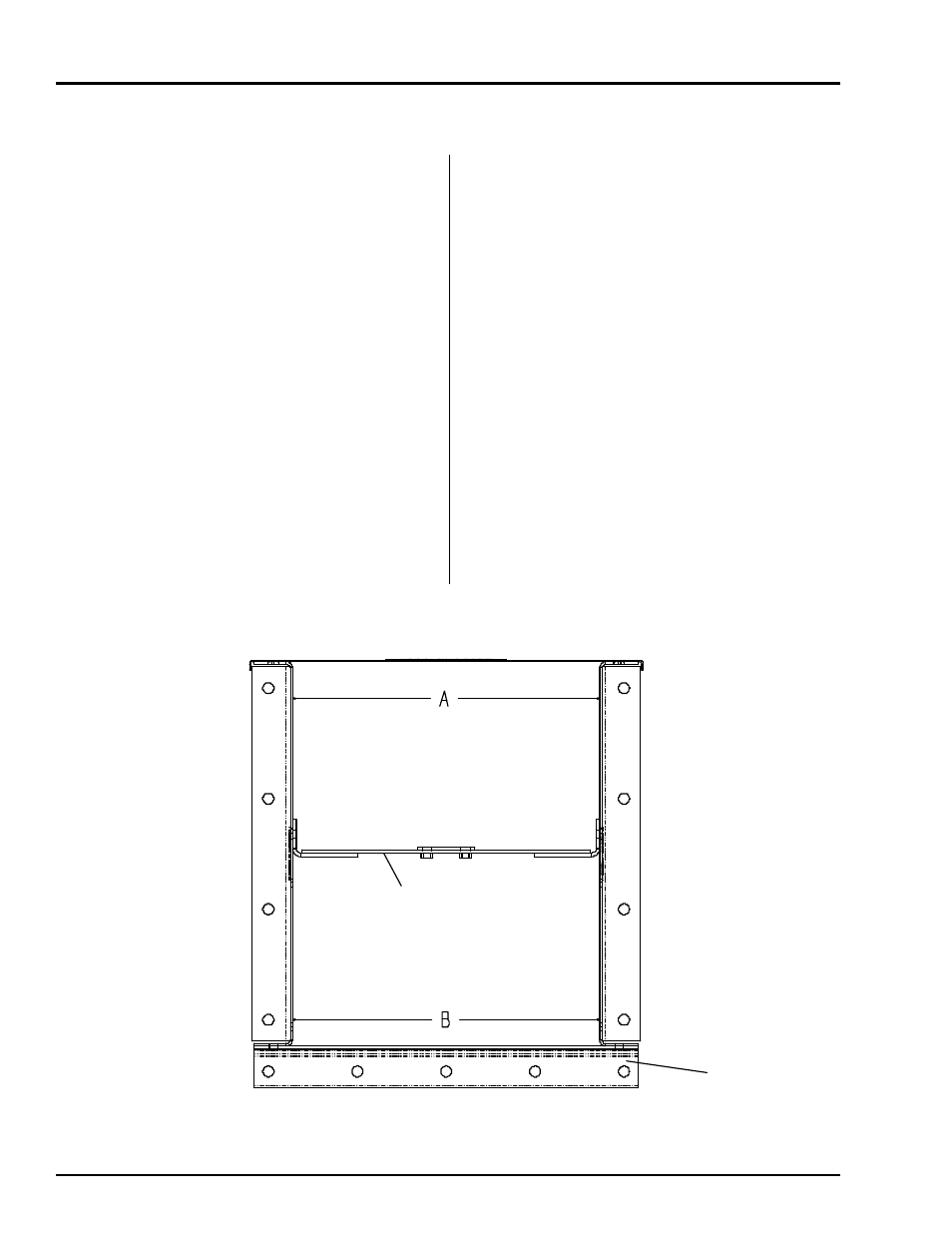

Note: It is critical for straitness of the conveyor

that the sides and bottom flanges are aligned flush.

Also, it is important that the inside dimensions of

the box measure equidistant from side-to-side both

top and bottom of the trough box (Dimension A =

Dimension B). See Fig. 5.

Intermediate Trough Section Assembly

FIG. 5

Center Pan Trough Section Shown

Bottom Plate

Center Pan