Banks Power Cummins Motorhomes: (Diesel ’98 - 03 ISB 5.9L) PowerPack TLC & Stinger TLC systems w_OttoMind Module 5.9L, Class-A MHExcept Comon Rail User Manual

Page 4

Remove as many loose chips as possible

from the exhaust manifold. A shop vacuum,

small brush or fingers will help. Now remove the

rag using a welding rod or coat hanger bent into

a hook. Caution! Make sure rags are removed

from exhaust manifold prior to reinstalling

turbocharger!

Install the thermocouple in the manifold

using anti-seize on the threads.

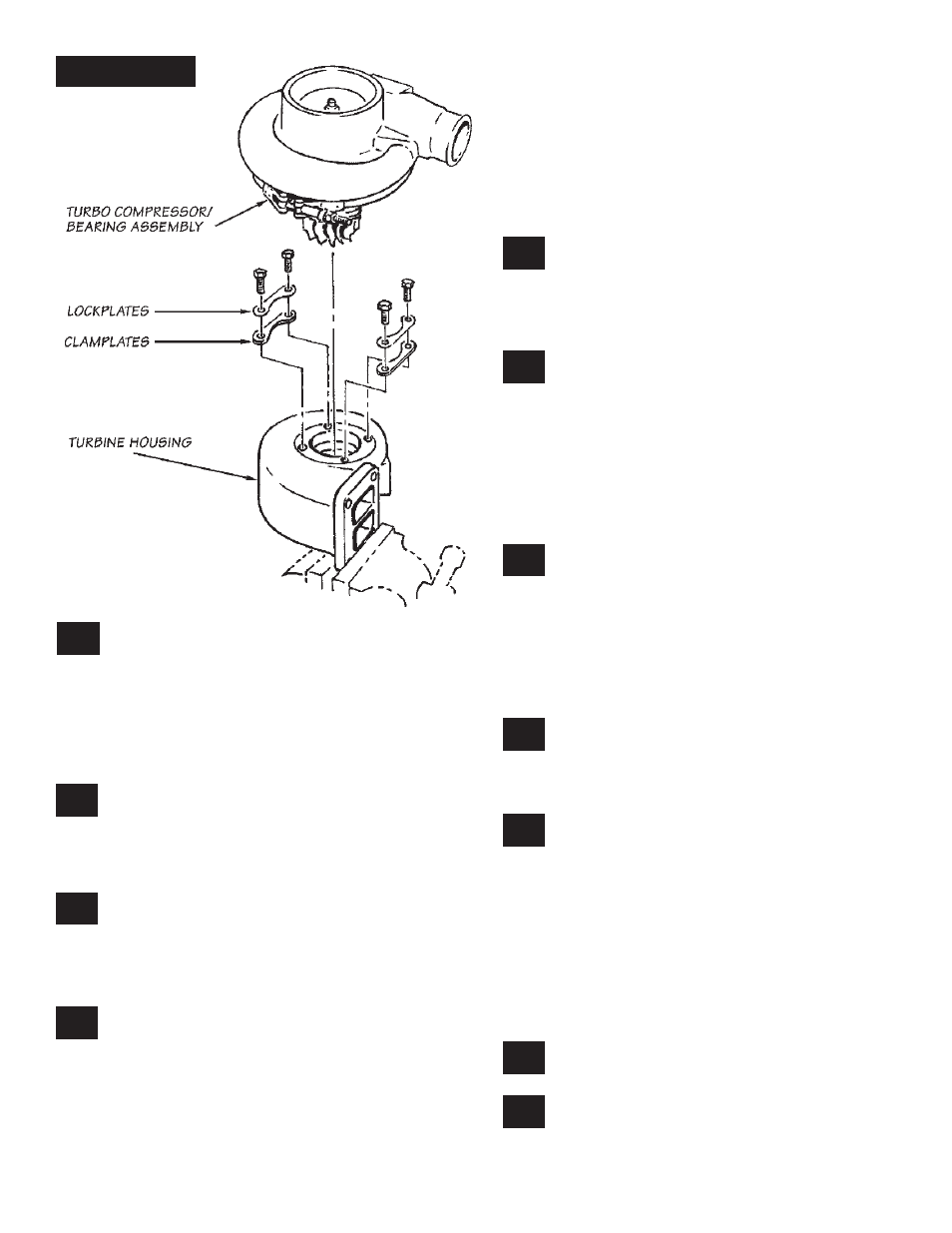

TURBOCHARGER DISASSEMBLY AND

RE-ASSEMBLY

Clamp the turbine inlet flange of the

turbocharger in a bench vise. Loosen the

four bolts attaching the turbine housing to the

center bearing section of the turbocharger. See

Figure 2

.

Remove the bolts, lock plates, and clamp

plates. Carefully remove the center bearing

and compressor assembly from the cast iron

turbine housing. If the turbocharger has been

in service for some time, rust and carbon may

prevent the center bearing and compressor

assembly from easily separating from the turbine

housing. If light hammer blows, penetrating oil or

heat will not free the compressor assembly from

the turbine housing, the clamp bolt adjacent to

the turbo oil inlet connection may be backed out

so as to push against the bearing casting and

separate the two components. Remove any loose

rust or carbon from the bearing housing that

might prevent proper engagement into the new

turbine housing.

Install the center bearing and compressor

assembly into the new turbine housing.

Apply a dab of anti-seize compound to the bolts,

and then install bolts, clamp plates, and lock

plates finger-tight to allow for final positioning.

Remove the exhaust outlet adapter from the

rear of the turbine housing. Using the new

gasket provided install the turbo exhaust outlet

adapter to the turbine housing with five 8mm x

20mm metric hex bolts. Apply a dab of anti-seize

compound to the bolts, then torque the bolts to

11.3 N-m (100 in/lbs.).

TURBOCHARGER INSTALLATION

Install the new turbine inlet gasket provided

and apply a dab of anti-seize compound

to the four turbo mounting studs. Install the

turbocharger on the exhaust manifold. As the

turbocharger is reinstalled, slip the oil drain tube

into the drain hose. Tighten the turbocharger

mounting nuts to 24 ft-lbs. Tighten the oil drain

hose clamp

.

Align the compressor outlet with the

intercooler hose adapter and tighten the

clamp. Tighten the turbine housing clamp plate

bolts to 11.3N-m (100 in-lb.) torque.

Spin the turbocharger shaft to make sure

it turns freely. If not, loosen the turbine

clamp plate bolts and check for misalignment

between the turbine housing and turbocharger

center section. Retighten bolts and check again.

NOTE: If alignment cannot be achieved by

loosening and retightening the bolts, it may be

necessary to clean rust or deposits from the

engaging portion of the center bearing housing.

Refer back to step 13.

Reconnect and tighten the turbo oil .

Install the air inlet tube (from the aircleaner

housing) and the turbo exhaust pipe

onto the turbocharger. Reattach the wastegate

actuator boost line using a crimp lock clamp

10.

11.

12.

13.

15.

16.

17.

18.

19.

20.

14.

Figure 2

P.N. 96398

4