Milton CAT 160M User Manual

Page 9

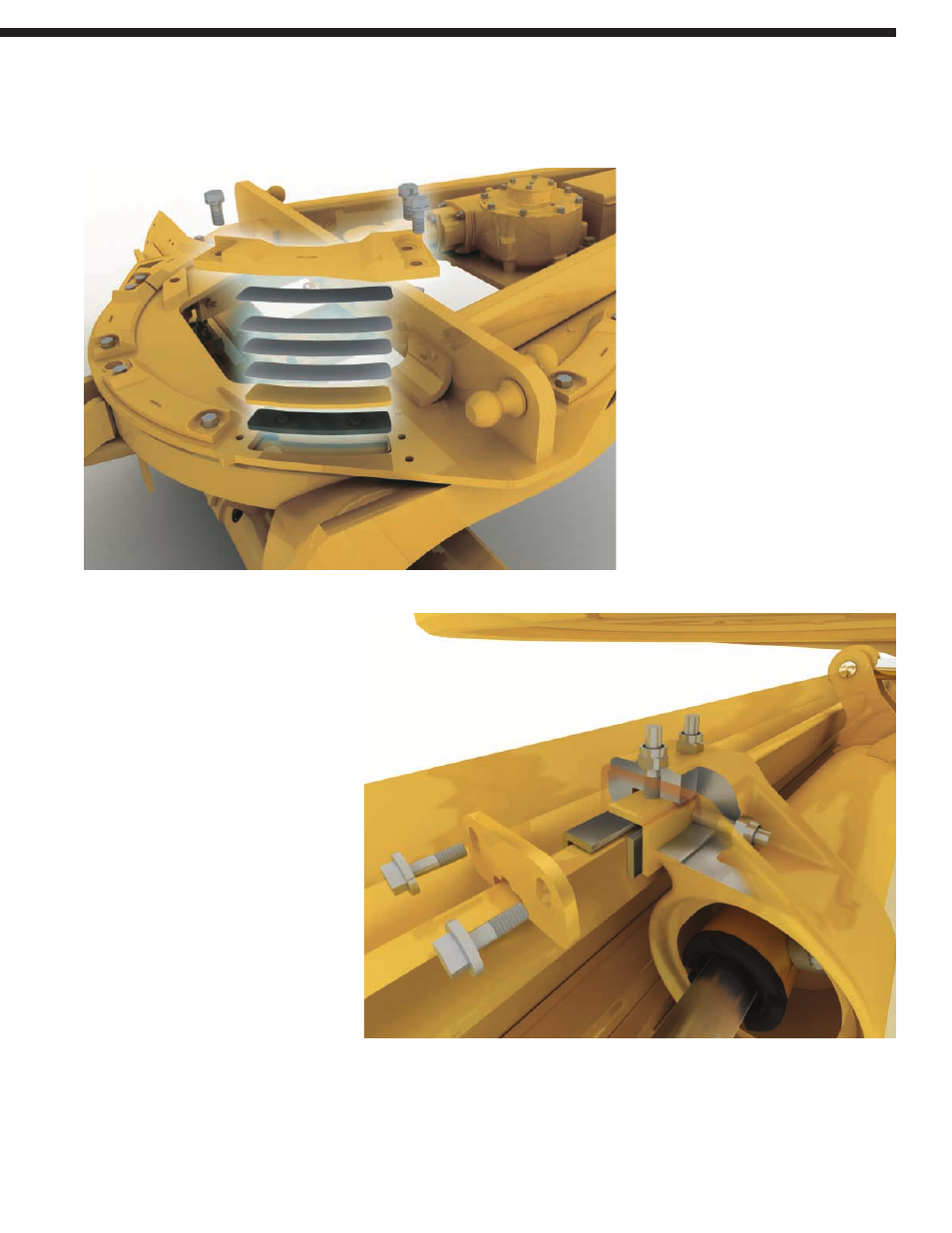

Top-Adjust Drawbar Wear Strips.

The patented top-adjust wear strips

dramatically reduce drawbar/circle

adjustment time. By removing the

access plates on top of the drawbar,

shims and wear strips can easily be

added or replaced. This feature reduces

service downtime and lowers overall

machine operating costs.

Replaceable Wear Inserts. Tough,

durable nylon composite wear inserts

reduce rotational friction for maximum

circle torque and longer component life.

They are located between the drawbar

and circle, and between the support

shoes and circle. High load-resistant

brass wearstrips are placed between the

blade mounting group and moldboard.

This sacrificial wear system can

be replaced easily and helps keep

components tight for fine grading.

Moldboard. The optimal curvature and

large throat clearance help move material

quickly and efficiently. Heat-treated

moldboard rails, hardened cutting edges

and end bits, and large diameter bolts

assure reliability and longer service life.

The moldboard side shift cylinder is

positioned on the left side to eliminate

snow wing interference.

Moldboard Positioning. The blade link

bar design extends the possibilities for

moldboard positioning, most beneficial

in mid-range bank sloping and in ditch

cutting and cleaning.

Shimless Moldboard Retention System.

The unique shimless moldboard retention

system reduces the potential for blade

chatter. Vertical and horizontal adjusting

screws keep the moldboard’s wear strips

aligned for precise blade control and

dramatic reductions in service time.

9

Shimless moldboard retention system with adjusting screws

Top-adjust drawbar wear strips