Information and monitoring systems – Milton CAT 772 User Manual

Page 18

New Features.

•

Standard Messenger Display replaces

Caterpillar Electronic Monitoring

System (CEMS) unit.

•

Enhanced TPMS (Optional

Attachment) incorporates second

gear weighing capability and

increases to 2,400 cycles of

data storage for analysis.

Cat Messenger. Standard on the 772, Cat

Messenger provides real-time machine

performance and operating data, and

basic trip, maintenance and diagnostic

data using an LCD display. The viewable

LCD screen area of the Messenger

display is 22.5 mm

ן 84.6 mm

(0.89 in

ן 3.33 in).

Service Mode. This allows a technician to

change machine settings that are typically

changed via Cat ET through the display.

Service Mode can be a password-

protected feature to inhibit the operator

from changing these settings. Settings that

can be changed via Service Mode are:

•

Top Gear Limit

•

Body Up Gear Limit

•

Machine Overloaded Speed Limit

(if TPMS is installed)

•

Machine Speed Limit

•

Economy Shift Mode

•

Desired Engine Retard Speed

•

Target Payload (if TPMS is installed)

•

Payload Overload Limit

(if TPMS is installed)

Real Time System Parameter Display.

This will show a real-time display of

various machine parameters related to

the engine, transmission, hoist, brake

and TPMS (if installed) systems.

• System Tests. The technician can

perform a transmission stall test and

a monitoring system self test.

• Machine Functionality. Records and

displays worst-case values for brake,

hoist and hydraulic fan oil temperature,

engine coolant temperature, tachometer,

transmission/torque converter temperature,

and fuel level since the last reset.

• System Information. Displays electronic

system information such as the ECM part

number, the software part number and

the software release date.

• Supports Multiple Languages.

Available in 47 languages. Please consult

with your salesman as to specific

language availability.

• Payload Calibration.

(if TPMS is installed)

18

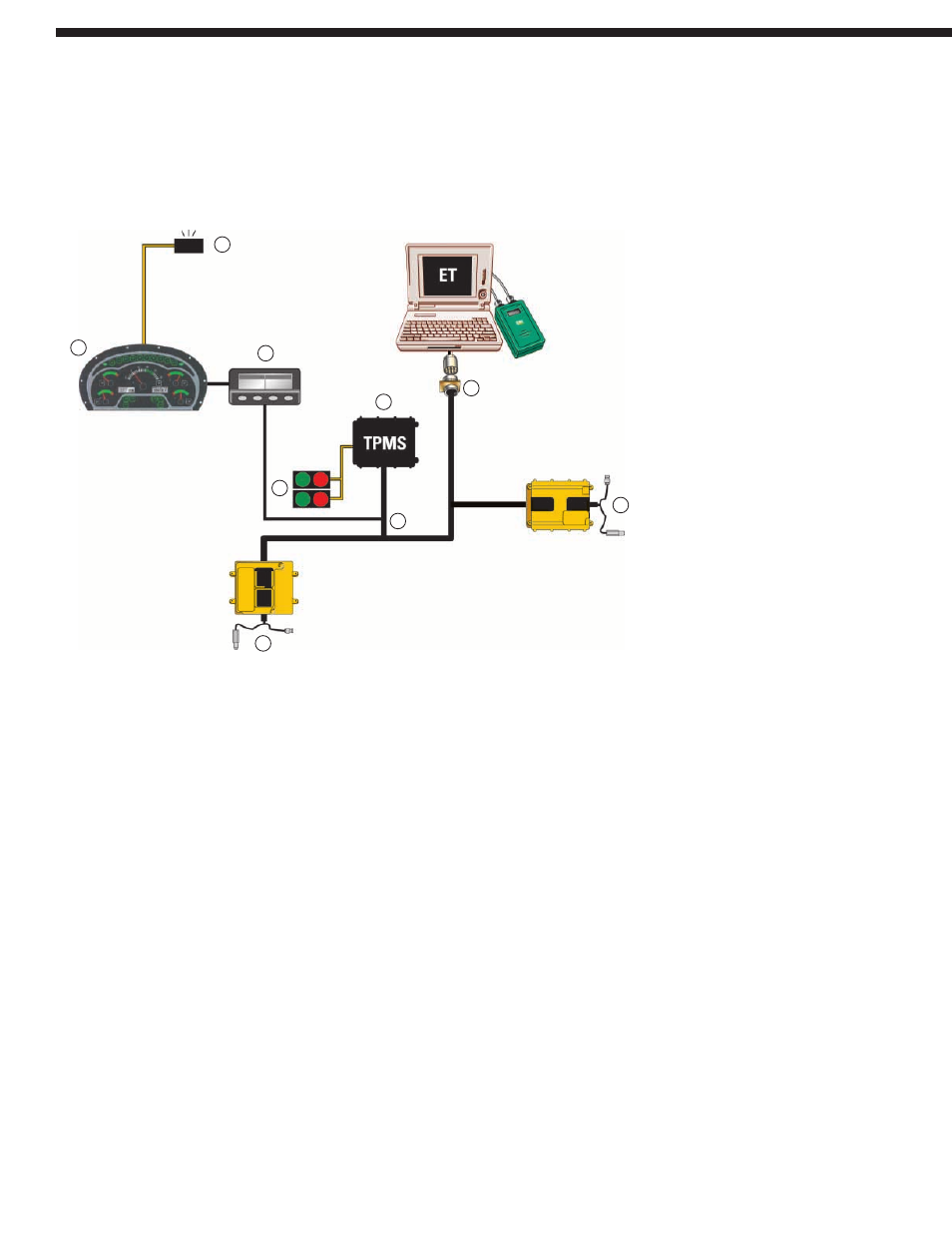

Vital machine health and payload data keeps the 772 performing at peak production levels.

Information and Monitoring Systems

5

4

2

1 Gauge Cluster

2 Messenger Display

3 Action Alarm

4 ADEM A4 Engine Control Module

5 CAT Data Link

6 Payload Lamps

7 Truck Production Management System

8 Diagnostic Connector (ET)

9 Automatic Retarder Control (ARC)

Traction Control System (TCS)

Transmission/Chassis Control (TCC) Module

9

8

6

1

3

7