Information & monitoring systems – Milton CAT 773F User Manual

Page 13

13

Instrument Cluster. Critical operating

information on the 773F is relayed

via the Cat Data Link to five gauges,

18 LED indicator lights, and an LCD

digital display.

Cat Messenger. Standard on the 773F,

Cat Messenger provides real-time

machine performance and operating

data, and basic trip, maintenance, and

diagnostic data using an LCD display.

The viewable LCD screen area of the

Messenger display is 22.5 mm

ן

84.6 mm (0.89 in

ן 3.33 in).

Truck Production Management System

(TPMS) (optional). TPMS provides

valuable payload and cycle time data

to improve productivity.

•

Uses strut pressure sensors and on-

board microprocessor to determine

payload weight.

•

Delivers consistent, accurate

payloads and improves efficiency

by minimizing overloading and

underloading.

•

External lights signal loading tool

operator when payload is reached.

•

On-board computer stores up to

2,400 cycles for analysis of payload

weight, cycle times, distances, and

actual cycle dates and times.

•

A second gear reweigh takes an

additional measurement once the

truck has reached second gear for

improved accuracy.

•

System is accurate within

± 5 percent under normal loading

conditions over a normal shift.

•

Standard LED lamps replace

incandescent lamps on the TPMS,

extending lamp life by 25 times.

VIMS™ Monitoring System (optional).

Caterpillar designed machine monitoring

system provides more than 250 machine

parameters, critical machine health and

payload data in real-time to keep the

773F performing at top production levels.

Product Link (optional). Now available

out of the factory, this system streamlines

diagnostic efforts, downtime, and

maintenance scheduling and costs by

providing a two-way communication

flow of vital machine data and location

information between the dealer and

the customer. Product Link provides

updates on service meter hours, machine

condition, machine location as well as

integrated mapping/route planning.

MineStar™ Ready. MineStar information

management system helps meet the

challenges of the mining industry by

linking the machines in the field with

business and operating systems to

ensure peak performance of mining

assets at the lowest possible cost.

These products deliver customers

everything from real-time machine

health information to GPS-guided

production aids. The 773F is equipped

for quick and easy installation of

MineStar™ information management

system products.

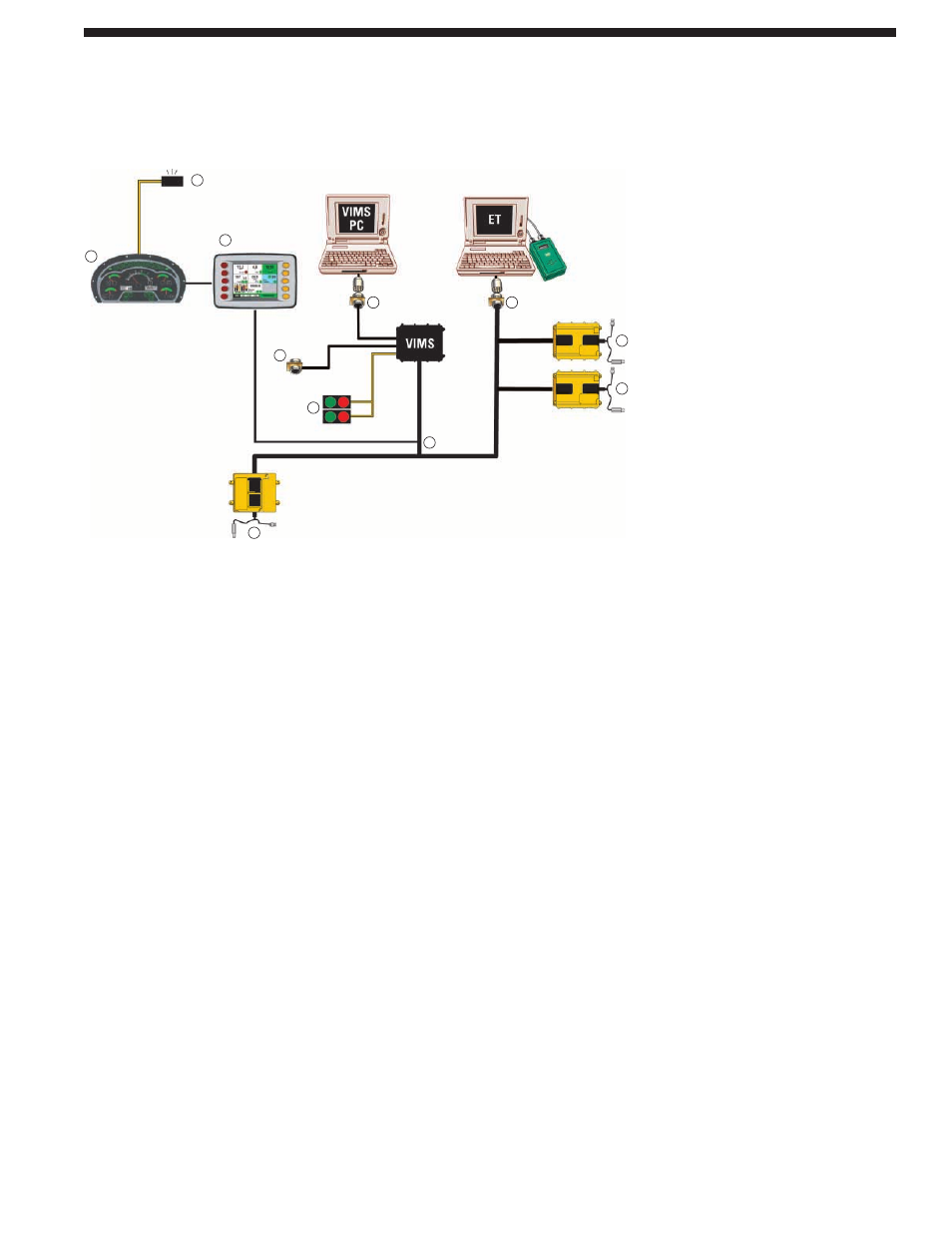

Information & Monitoring Systems

Vital machine health and payload data keeps the 773F performing at peak production levels.

9

10

5

2

8

7

6

1

3

11

4

1 Gauge Cluster

2 Advisor Display

3 Action Alarm

4 ADEM A4 Engine Control Module

5 CAT Data Link

6 Payload Lamps

7 Data Port (VIMS-PC)

8 Diagnostic Connector (ET)

9 Automatic Retarder Control (ARC) and

Traction Control System (TCS)

10 Transmission/Chassis Control (TCC) Module

11 Telemetry Port