70mt..kpbf series, Vishay high power products, Three phase bridge (power modules), 60/70 a – C&H Technology 60-70MT..KPbF Series User Manual

Page 3

www.vishay.com

For technical questions, contact: [email protected]

Document Number: 94356

2

Revision: 29-Apr-08

60-70MT..KPbF Series

Vishay High Power Products

Three Phase Bridge

(Power Modules), 60/70 A

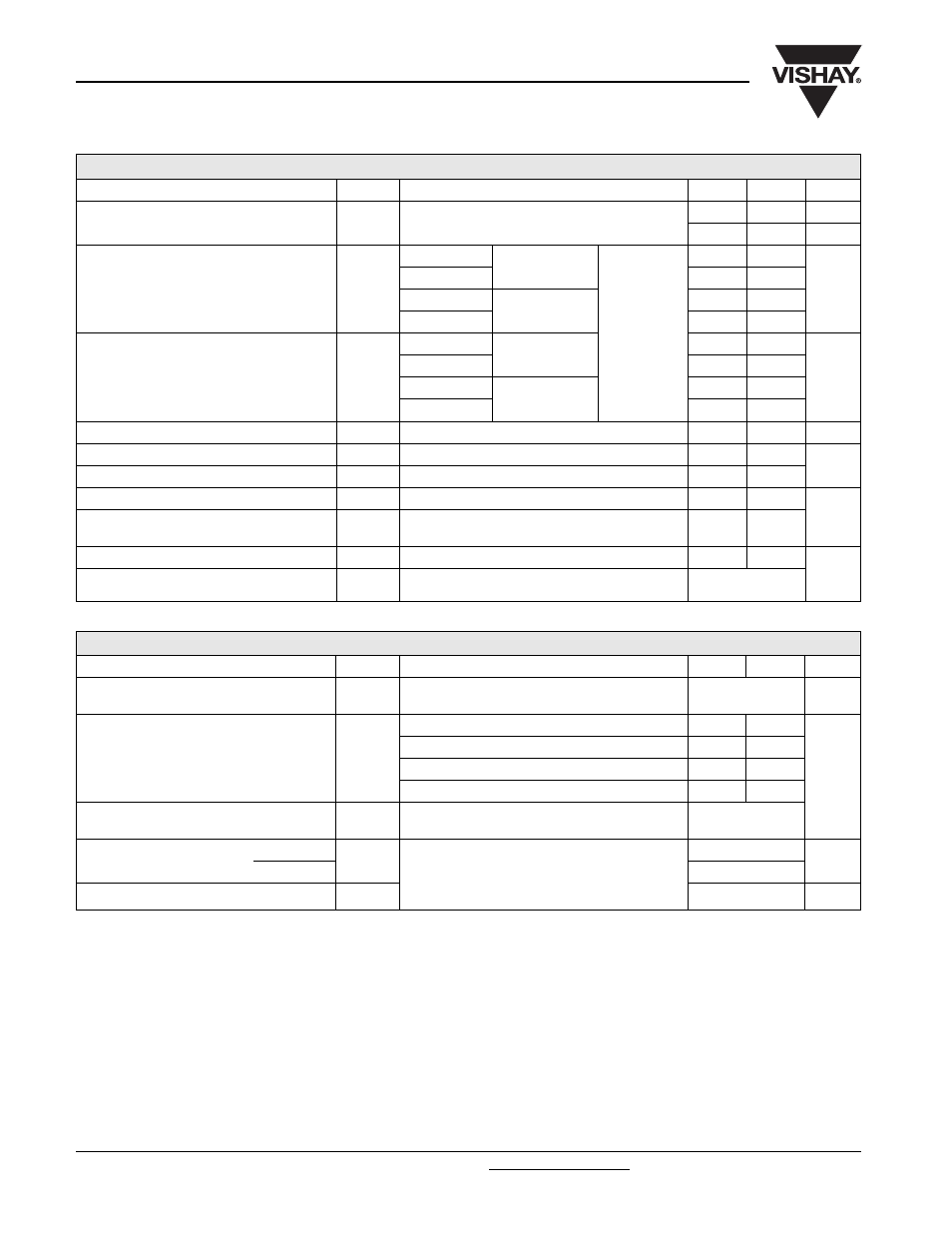

FORWARD CONDUCTION

PARAMETER

SYMBOL

TEST CONDITIONS

60MT.K

70MT.K

UNITS

Maximum DC output

current at case temperature

I

O

120° rect. conduction angle

60 (75)

70 (90)

A

85 (61)

85 (57)

°C

Maximum peak, one-cycle

forward, non-repetitive

surge current

I

FSM

t = 10 ms

No voltage

reapplied

Initial

T

J

= T

J

maximum

420

480

A

t = 8.3 ms

440

500

t = 10 ms

100 % V

RRM

reapplied

350

400

t = 8.3 ms

370

420

Maximum I

2

t for fusing

I

2

t

t = 10 ms

No voltage

reapplied

870

1150

kA

2

s

t = 8.3 ms

790

1050

t = 10 ms

100 % V

RRM

reapplied

610

800

t = 8.3 ms

560

730

Maximum I

2

√t for fusing

I

2

√t

t = 0.1 to 10 ms, no voltage reapplied

8700

11 300

A

2

√s

Low level value of threshold voltage

V

F(TO)1

(16.7 % x

π x I

F(AV)

< I <

π × I

F(AV)

), T

J

maximum

0.85

0.86

V

High level value of threshold voltage

V

F(TO)2

(I >

π x I

F(AV)

), T

J

maximum

1.07

1.08

Low level value of forward slope resistance

r

f1

(16.7 % x

π x I

F(AV)

< I <

π × I

F(AV)

), T

J

maximum

8.04

7.35

m

Ω

High level value of forward

slope resistance

r

f2

(I >

π x I

F(AV)

), T

J

maximum

7.08

6.53

Maximum forward voltage drop

V

FM

I

pk

= 100 A, T

J

= 25 °C, t

p

= 400 µs single junction

1.75

1.55

V

RMS isolation voltage

V

ISOL

T

J

= 25 °C, all terminal shorted

f = 50 Hz, t = 1 s

4000

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

60MT.K

70MT.K

UNITS

Maximum junction operating and

storage temperature range

T

J

, T

Stg

- 40 to 150

°C

Maximum thermal resistance,

junction to case

R

thJC

DC operation per module

0.37

0.29

K/W

DC operation per junction

2.22

1.75

120° rect. conduction angle per module

0.40

0.34

120° rect. conduction angle per junction

2.42

2.01

Maximum thermal resistance,

case to heatsink per module

R

thCS

Mounting surface smooth, flat and greased

0.03

Mounting torque ± 10 %

to heatsink

A mounting compound is recommended and

the torque should be rechecked after a period

of 3 hours to allow for the spread of the

compound. Lubricated threads.

4 to 6

Nm

to terminal

3 to 4

Approximate weight

176

g