Vsk.41.., vsk.56.. series, Vishay high power products – C&H Technology VSK.56.. Series User Manual

Page 4

Document Number: 94630

For technical questions, contact:

www.vishay.com

Revision: 05-Aug-09

3

VSK.41.., VSK.56.. Series

ADD-A-PAK Generation VII Power Modules

Thyristor/Diode and Thyristor/Thyristor, 45 A/60 A

Vishay High Power Products

Note

•

Table shows the increment of thermal resistance R

thJC

when devices operate at different conduction angles than DC

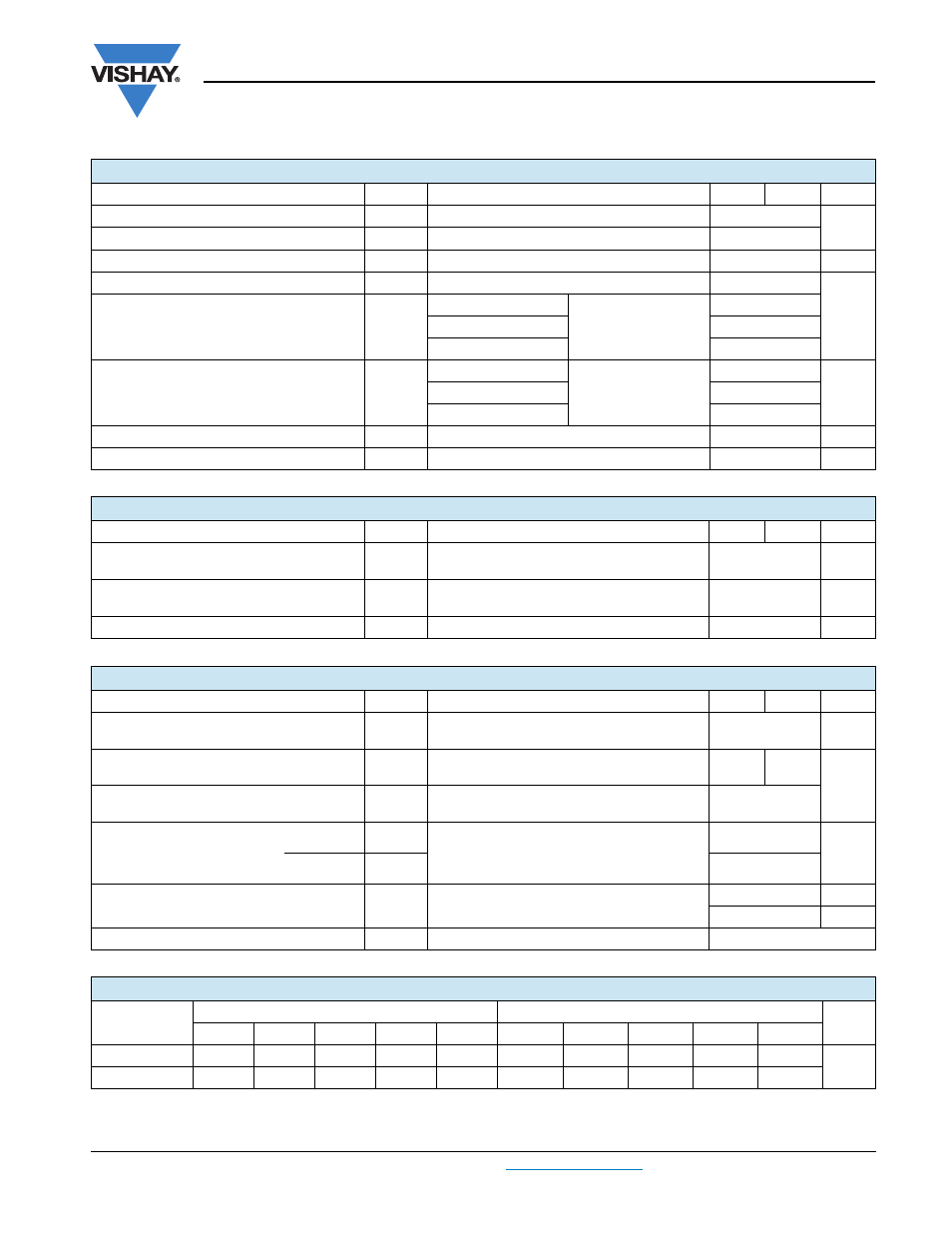

TRIGGERING

PARAMETER

SYMBOL

TEST CONDITIONS

VSK.41

VSK.56

UNITS

Maximum peak gate power

P

GM

10

W

Maximum average gate power

P

G(AV)

2.5

Maximum peak gate current

I

GM

2.5

A

Maximum peak negative gate voltage

- V

GM

10

V

Maximum gate voltage required to trigger

V

GT

T

J

= - 40 °C

Anode supply = 6 V

resistive load

4.0

T

J

= 25 °C

2.5

T

J

= 125 °C

1.7

Maximum gate current required to trigger

I

GT

T

J

= - 40 °C

Anode supply = 6 V

resistive load

270

mA

T

J

= 25 °C

150

T

J

= 125 °C

80

Maximum gate voltage that will not trigger

V

GD

T

J

= 125 °C, rated V

DRM

applied

0.25

V

Maximum gate current that will not trigger

I

GD

T

J

= 125 °C, rated V

DRM

applied

6

mA

BLOCKING

PARAMETER

SYMBOL

TEST CONDITIONS

VSK.41

VSK.56

UNITS

Maximum peak reverse and off-state

leakage current at V

RRM

, V

DRM

I

RRM,

I

DRM

T

J

= 125 °C, gate open circuit

15

mA

Maximum RMS insulation voltage

V

INS

50 Hz

3000 (1 min)

3600 (1 s)

V

Maximum critical rate of rise of off-state voltage

dV/dt

T

J

= 125 °C, linear to 0.67 V

DRM

1000

V/µs

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

VSK.41

VSK.56

UNITS

Junction operating and storage

temperature range

T

J

, T

Stg

- 40 to 125

°C

Maximum internal thermal resistance,

junction to case per leg

R

thJC

DC operation

0.44

0.35

°C/W

Typical thermal resistance,

case to heatsink per module

R

thCS

Mounting surface flat, smooth and greased

0.1

Mounting torque ± 10 %

to heatsink

A mounting compound is recommended and the

torque should be rechecked after a period of

3 h to allow for the spread of the compound.

4

Nm

busbar

3

Approximate weight

75

g

2.7

oz.

Case style

JEDEC

TO-240AA compatible

ΔR CONDUCTION PER JUNCTION

DEVICES

SINE HALF WAVE CONDUCTION

RECTANGULAR WAVE CONDUCTION

UNITS

180°

120°

90°

60°

30°

180°

120°

90°

60°

30°

VSK.41..

0.110

0.131

0.17

0.23

0.342

0.085

0.138

0.177

0.235

0.345

°C/W

VSK.56..

0.088

0.104

0.134

0.184

0.273

0.07

0.111

0.143

0.189

0.275