Cp high volume, Vishay dale – C&H Technology CP-High-Volume User Manual

Page 3

www.vishay.com

41

CP High Volume

Vishay Dale

For technical questions, contact [email protected]

Document Number 30113

Revision 12-Jan-06

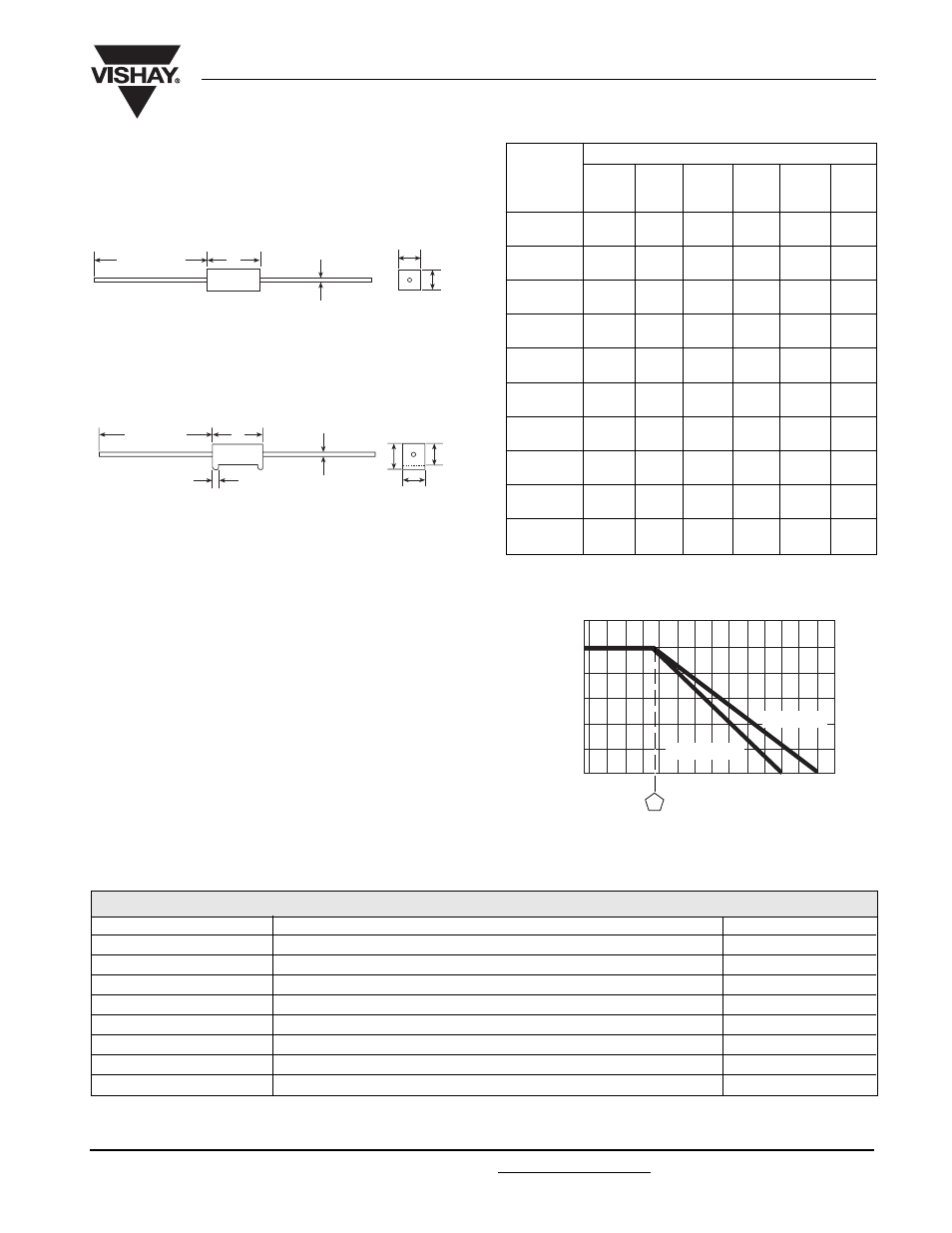

DIMENSIONS

CPxxxx...3

0.125 [3.18]

Typical

LL

L

H

W

H1

LD

CPxxxx

LL

LD

W

H

L

GLOBAL

DIMENSIONS in millimeters [inches]

MODEL

L*

W

H

H1

LD

LL

±

1.5

±

1.0

±

1.0

±

1.5

±

0.05

±

3.0

[0.060]

[0.040]

[0.040]

[0.060]

[0.002] [0.120]

CP0002

18

7

7

—

0.65

35

[0.71]

[0.276]

[0.276]

[0.0256] [1.378]

CP0003

22

8

8

—

0.8

35

[0.87]

[0.315]

[0.315]

[0.031]

[1.378]

CP0005

22

10

9

—

0.8

35

[0.87]

[0.394]

[0.354]

[0.031]

[1.378]

CP0005...3

22

10

9

10.5

0.8

35

[0.87]

[0.394]

[0.354]

[0.413]

[0.031]

[1.378]

CP0007

35

10

9

—

0.8

35

[1.38]

[0.394]

[0.354]

[0.031]

[1.378]

CP0007...3

35

10

9

12

0.8

35

[1.38]

[0.394]

[0.354]

[0.472]

[0.031]

[1.378]

CP0010

48

10

9

—

0.8

35

[1.89]

[0.394]

[0.354]

[0.031]

[1.378]

CP0010...3

48

10

9

12

0.8

35

[1.89]

[0.394]

[0.354]

[0.472]

[0.031]

[1.378]

CP0015

48

12.5

11.5

—

0.8

35

[1.89]

[0.492]

[0.453]

[0.031]

[1.378]

CP0020

60

14

13.5

—

0.8

35

[2.36]

[0.551]

[0.531]

[0.031]

[1.378]

Wirewound/Metal Oxide Resistors, Commercial Power,

Axial Lead

MATERIAL SPECIFICATIONS

Element: Wirewound = Copper-nickel alloy or nickel -

chrome alloy, depending on resistance value

Metal Oxide = High temperature fired Metal Oxide film

Core: Wirewound = Woven fiberglass

Metal Oxide = Ceramic

Body: Steatite ceramic case with cement potting

compound

End Caps: Tin plated steel

Terminals: Tinned copper

Part Marking: DALE, Model, Wattage, Value, Tolerance,

Date Code

PERFORMANCE

TEST

CONDITIONS OF TEST

TEST LIMITS

Thermal Shock

- 55 °C to + 275 °C (+ 225 °C for Metal Oxide), 5 cycles, 30 minute dwell time

± (5.0 % + 0.05 Ω) ∆R

Short Time Overload

5 x rated power for 5 seconds

± (4.0 % + 0.05 Ω) ∆R

Dielectric Withstanding Voltage

1000 V

rms

for one minute

± (2.0 % + 0.05 Ω) ∆R

Low Temperature Operation

- 65 °C, full rated working voltage for 45 minutes

± (3.0 % + 0.05 Ω) ∆R

Humidity

75 °C, 90 % - 100 % RH, 240 hours

± (5.0 % + 0.05 Ω) ∆R

Load Life

1000 hours at rated power, + 25 °C, 1.5 hours "ON", 0.5 hours "OFF"

± (10.0 % + 0.05 Ω) ∆R

Terminal Strength

5 pounds for 30 seconds; body twisted about axis, 3 360° rotations

± (2.0 % + 0.05 Ω) ∆R

Resistance to Solder Heat

Terminal immersed 3.5 seconds in molten solder at 1/8" to 3/16" from body

± (4.0 % + 0.05 Ω) ∆R

Derating

120

100

80

60

40

20

0

RA

TED POWER IN %

- 65 - 25 25 75 125 175 225 275

AMBIENT TEMPERATURE IN

°

C

Wirewound

Metal Oxide

40

* Potting compound may extend outside of ceramic case up to

1.52 mm [0.060"] maximum per side.