Vskd600.. series, Vishay high power products, Standard diodes, 600 a (super magn-a-pak – C&H Technology VSKD600.. Series User Manual

Page 3: Power modules)

www.vishay.com

For technical questions, contact: [email protected]

Document Number: 93583

2

Revision: 11-Aug-08

VSKD600.. Series

Vishay High Power Products

Standard Diodes, 600 A

(SUPER MAGN-A-PAK

TM

Power Modules)

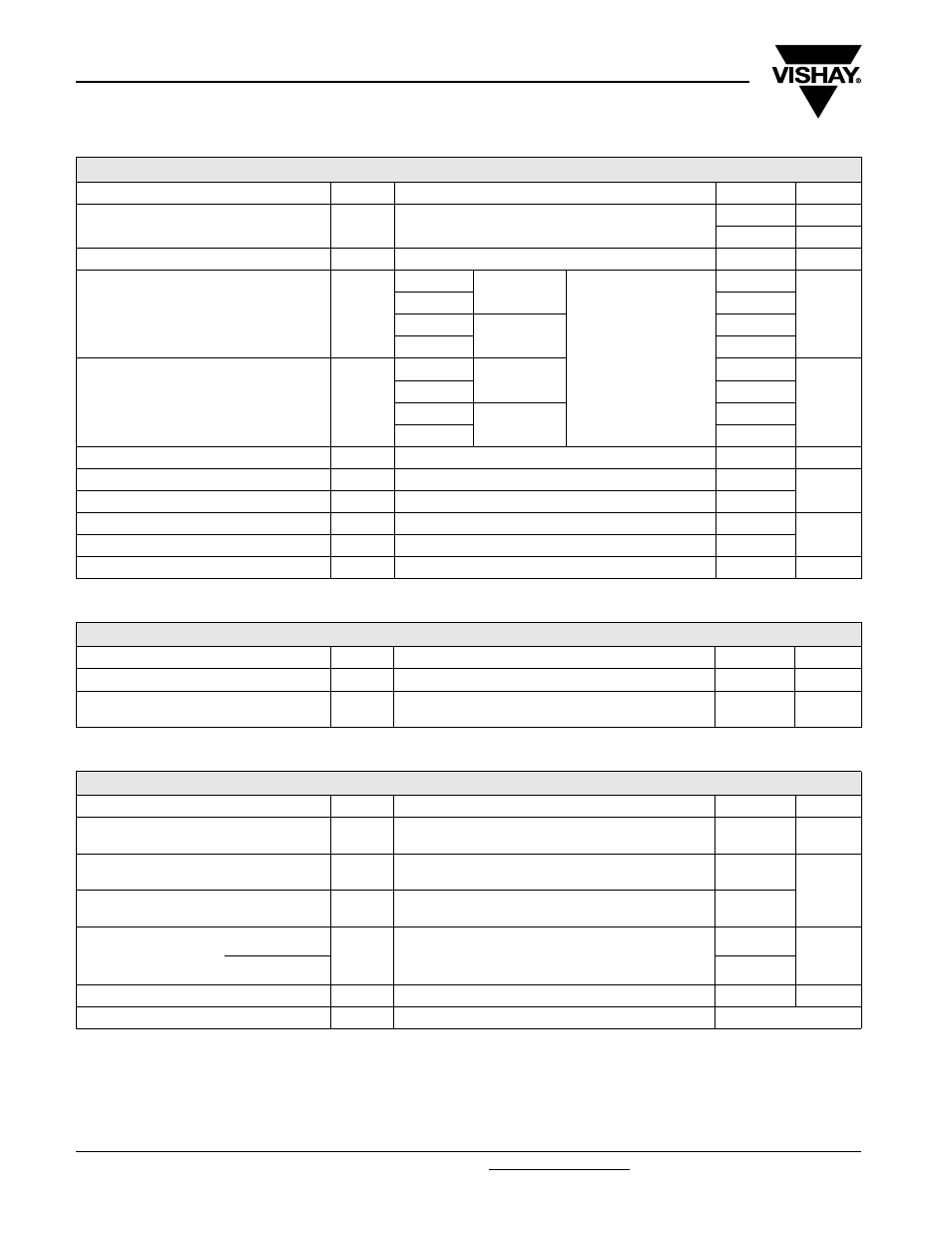

FORWARD CONDUCTION

PARAMETER

SYMBOL

TEST CONDITIONS

VALUES

UNITS

Maximum average forward current

at case temperature

I

F(AV)

180° conduction, half sine wave

600

A

100

°C

Maximum RMS forward current

I

F(RMS)

180° conduction, half sine wave at T

C

= 100 °C

942

A

Maximum peak, one-cycle forward,

non-repetitive surge current

I

FSM

t = 10 ms

No voltage

reapplied

Sinusoidal half wave,

initial T

J

= T

J

maximum

19.0

kA

t = 8.3 ms

20.1

t = 10 ms

100 % V

RRM

reapplied

16.2

t = 8.3 ms

17.2

Maximum I

2

t for fusing

I

2

t

t = 10 ms

No voltage

reapplied

1805

kA

2

s

t = 8.3 ms

1683

t = 10 ms

100 % V

RRM

reapplied

1319

t = 8.3 ms

1230

Maximum I

2

√t for fusing

I

2

√t

t = 0.1 to 10 ms, no voltage reapplied

18 050

kA

2

√s

Low level value of threshold voltage

V

F(TO)1

(16.7 % x

π x I

F(AV)

< I <

π x I

F(AV)

), T

J

= T

J

maximum

0.70

V

High level value of threshold voltage

V

F(TO)2

(I >

π x I

F(AV)

), T

J

= T

J

maximum

0.77

Low level value of forward slope resistance

r

f1

(16.7 % x

π x I

F(AV)

< I <

π x I

F(AV)

), T

J

= T

J

maximum

0.28

m

Ω

High level value of forward slope resistance

r

f2

(I

>

π x I

F(AV)

), T

J

= T

J

maximum

0.25

Maximum forward voltage drop

V

FM

I

pk

= 1800 A, T

J

= 25 °C, t

p

= 10 ms sine pulse

1.45

V

BLOCKING

PARAMETER

SYMBOL

TEST CONDITIONS

VALUES

UNITS

RMS insulation voltage

V

INS

t = 1 s

3000

V

Maximum peak reverse and

off-state leakage current

I

RRM

T

J

= T

J

maximum, rated V

RRM

applied

50

mA

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

VALUES

UNITS

Maximum junction operating and storage

temperature range

T

J

, T

Stg

- 40 to 150

°C

Maximum thermal resistance,

junction to case per junction

R

thJC

DC operation

0.065

K/W

Maximum thermal resistance,

case to heatsink

R

thC-hs

0.02

Mounting torque ± 10 %

SMAP to heatsink

A mounting compound is recommended and the torque

should be rechecked after a period of 3 hours to allow for

the spread of the compound.

6 to 8

Nm

busbar to SMAP

12 to 15

Approximate weight

1500

g

Case style

See dimensions - link at the end of datasheet

SUPER MAGN-A-PAK