Vishay semiconductors – C&H Technology VSKDS201-045 User Manual

Page 3

VSKDS201/045

www.vishay.com

Vishay Semiconductors

Revision: 04-Jan12

2

Document Number: 93234

For technical questions within your region:

,

,

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT

www.vishay.com/doc?91000

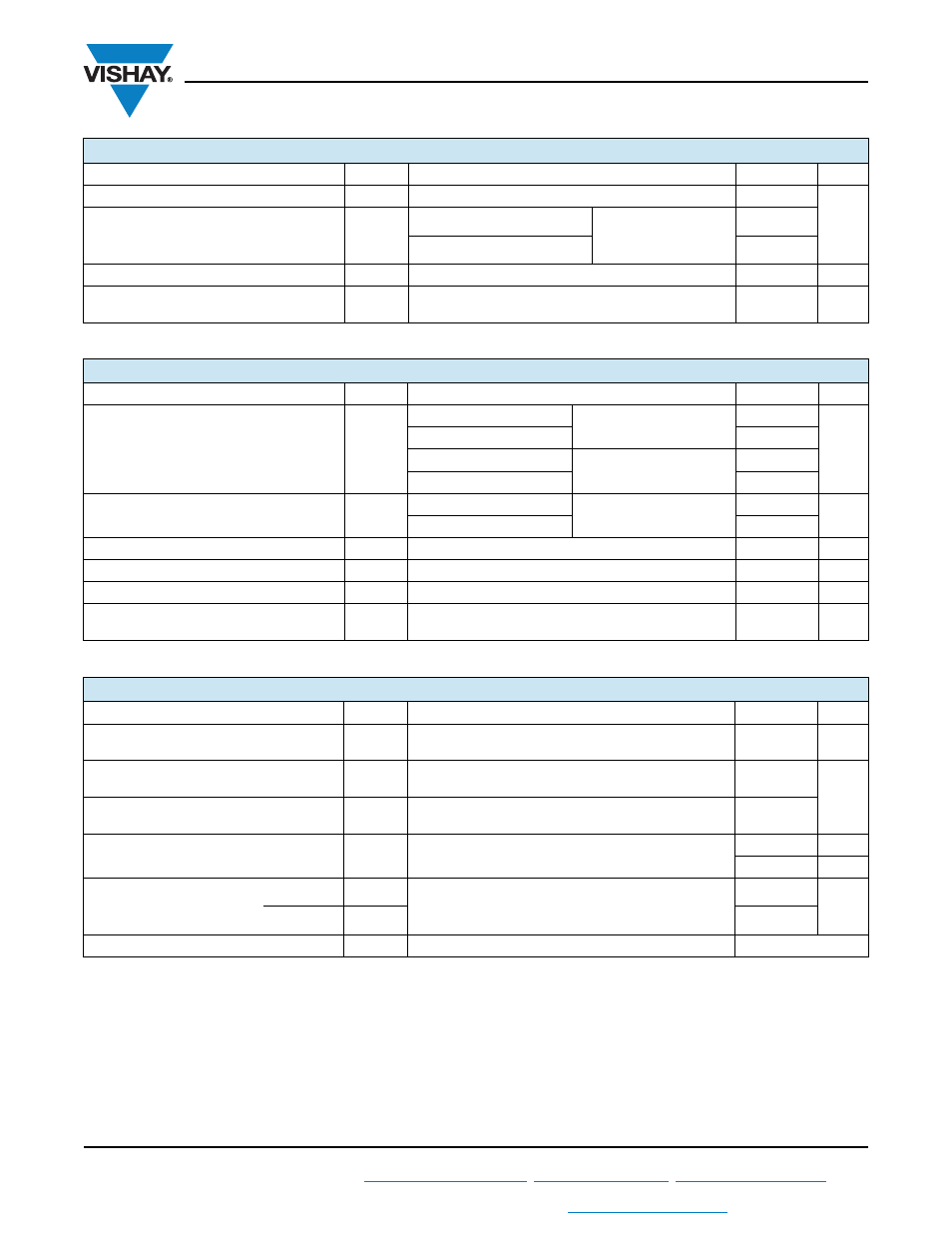

ABSOLUTE MAXIMUM RATINGS

PARAMETER

SYMBOL

TEST CONDITIONS

VALUES

UNITS

Maximum average forward current per leg

I

F(AV)

50 % duty cycle at T

C

= 123 °C, rectangular waveform

100

A

Maximum peak one cycle non-repetitive

surge current

I

FSM

5 μs sine or 3 μs rect. pulse

Following any rated

load condition and with

rated V

RRM

applied

8600

10 ms sine or 6 ms rect. pulse

1850

Non-repetitive avalanche energy

E

AS

T

J

= 25 °C, I

AS

= 24 A, L = 1 mH

270

mJ

Repetitive avalanche current

I

AR

Current decaying linearly to zero in 1 μs

Frequency limited by T

J

maximum V

A

= 1.5 x V

R

typical

20

A

ELECTRICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

VALUES

UNITS

Maximum forward voltage drop

V

FM

100 A

T

J

= 25 °C

0.72

V

200 A

1.04

100 A

T

J

= 125 °C

0.69

200 A

0.98

Maximum reverse leakage current

I

RM

T

J

= 25 °C

V

R

= Rated V

R

10

mA

T

J

= 125 °C

90

Maximum junction capacitance

C

T

V

R

= 5 V

DC

(test signal range 100 kHz to 1 MHz), 25 °C

5200

pF

Typical series inductance

L

S

Measured lead to lead 5 mm from package body

7.0

nH

Maximum voltage rate of change

dV/dt

Rated V

R

10 000

V/μs

Maximum RMS insulation voltage

V

INS

50 Hz

3000 (1 min)

3600 (1 s)

V

THERMAL - MECHANICAL SPECIFICATIONS

PARAMETER SYMBOL

TEST

CONDITIONS

VALUES

UNITS

Maximum junction and storage

temperature range

T

J

, T

Stg

- 55 to 175

°C

Maximum thermal resistance,

junction to case per leg

R

thJC

DC

operation

0.52

°C/W

Typical thermal resistance,

case to heatsink per module

R

thCS

0.1

Approximate weight

75

g

2.7

oz.

Mounting torque ± 10 %

to heatsink

A mounting compound is recommended and the torque

should be rechecked after a period of 3 hours to allow for

the spread of the compound.

4

Nm

busbar

3

Case style

JEDEC

TO-240AA compatible