VEGA VEGAPULS 66 (≥ 2.0.0 - ≥ 4.0.0) standpipe ver. Modbus and Levelmaster protocol User Manual

Page 45

45

11 Supplement

VEGAPULS 66 standpipe version • Modbus and Levelmaster protocol

41367-EN-121011

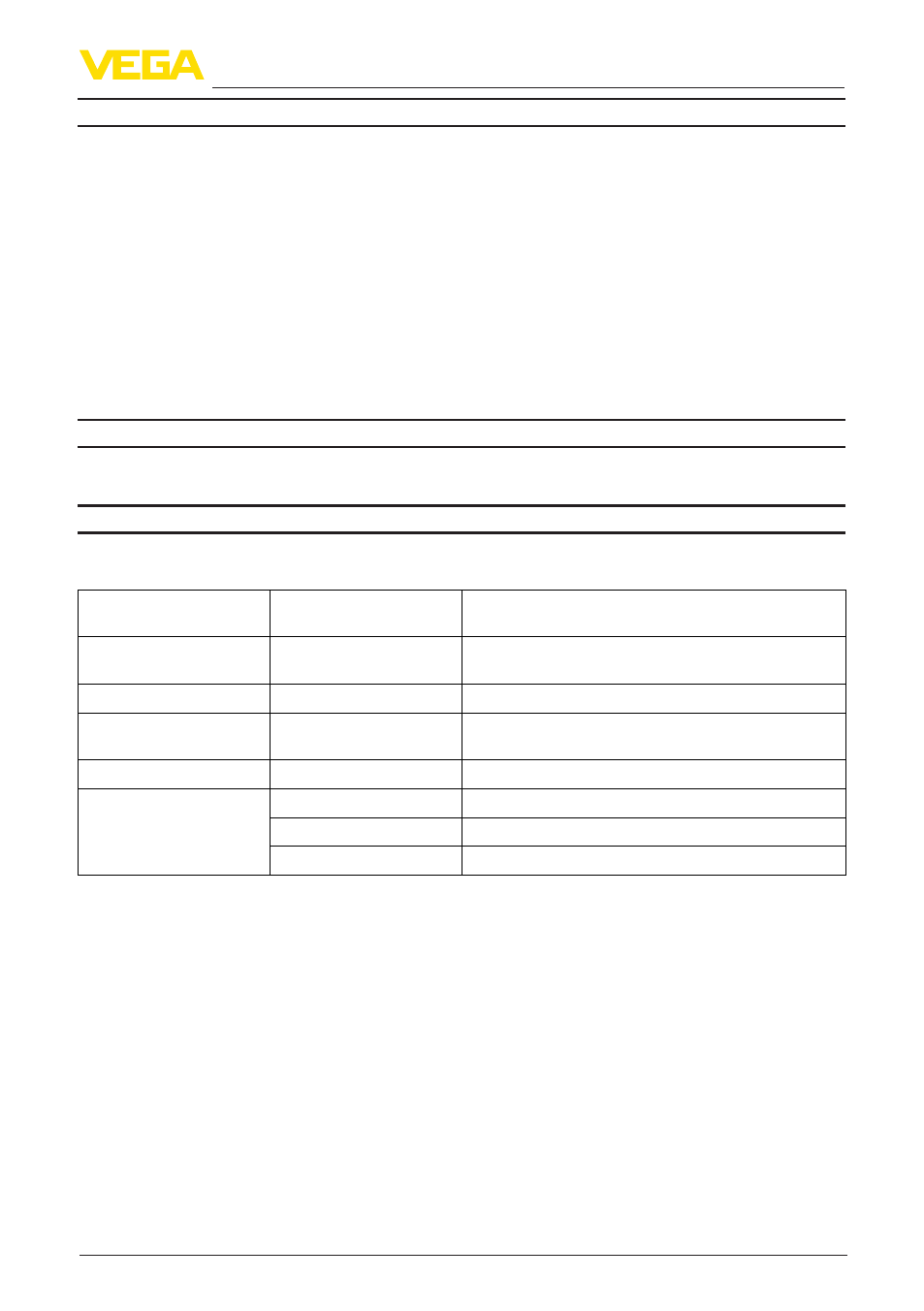

Characteristics and performance data

Measuring frequency

C-band (6 GHz technology)

Measuring cycle time approx.

350 ms

Step response time

2)

≤ 3 s

Tracking speed of the measuring window

max.

1 m/min

Emitted HF power (depending on the parameter adjustment)

3)

Ʋ Average spectral transmission power

density

-31 dBm/MHz EIRP

Ʋ Max. spectral transmission power

density

+24 dBm/50 MHz EIRP

Ʋ Specific absorption rate (SAR)

0.47 mW/kg

Ambient conditions

Ambient, storage and transport tempera-

ture

-40 … +80 °C (-40 … +176 °F)

Process conditions

For the process conditions, please also note the specifications on the type label. The lower value

always applies.

Seal

Antenna impedance

cone

Process temperature (measured on the process

fitting)

FKM (A+P GLT FPM

70.16-06)

PFFE

-40 … +150 °C (-40 … +302 °F)

FFKM (Kalrez 6375)

PFFE

-20 … +150 °C (-4 … +302 °F)

Silicone FEP coated (A+P

FEP-O-SEAL)

PFFE

-40 … +150 °C (-40 … +302 °F)

EPDM (A+P 75.5/KW/75F) PFFE

-40 … +150 °C (-40 … +302 °F)

Graphite

Ceramic

-60 … +250 °C (-76 … +482 °F)

Ceramic

-60 … +300 °C (-76 … +572 °F)

Ceramic

-60 … +400 °C (-76 … +752 °F)

Vessel pressure relating to the antenna cone

Ʋ PTFE

-100 … 4000 kPa/-1 … 40 bar (-14.5 … 580 psi) with

PN 40

Ʋ Ceramic

-100 … 16000 kPa/-1 … 160 bar (-14.5 … 2321 psi) with

PN 160

Vessel pressure relating to the flange

nominal stage

see supplementary instructions manual "Flanges ac-

cording to DIN-EN-ASME-JIS"

Vibration resistance

1 g at 5 … 200 Hz according to EN60068-2-6 (vibration

with resonance)

Shock resistance

100 g, 6 ms according to EN 60068-2-27 (mechanical

shock)

2)

Time span after a sudden measuring distance change by max. 0.5 m in liquid applications until the output signal

has taken for the first time 90 % of the final value (IEC 61298-2).

3)

EIRP: Equivalent Isotropic Radiated Power