VEGA VEGABAR 81 Save sensor - Operating Instructions User Manual

Page 29

29

6 Set up with the display and adjustment module

VEGABAR 81 • Slave sensor for electronic differential pressure

45049-EN-131011

Save your settings with [OK] and move with [ESC] and [->] to the

next menu item.

After the position correction is carried out, the actual measured value

is corrected to 0. The corrective value appears with an inverse sign as

offset value in the display.

The position correction can be repeated as often as necessary. How-

ever, if the sum of the corrective values exceeds 20 % of the nominal

measuring range, then no position correction is possible.

VEGABAR 81 always measures pressure independently of the pro-

cess variable selected in the menu item "Application". To output the

selected process variable correctly, an allocation to 0 % and 100 % of

the output signal must be carried out (adjustment).

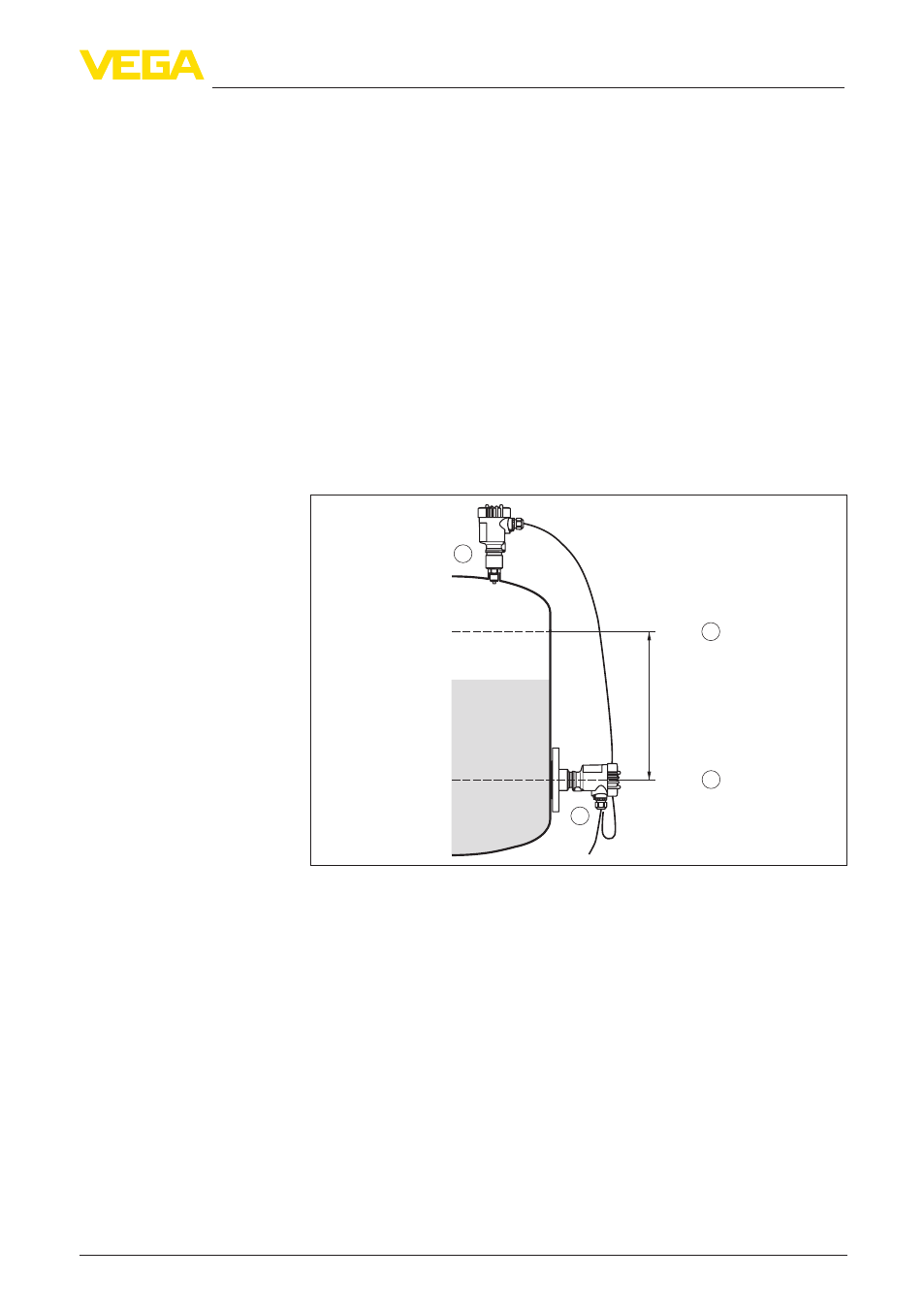

With the application "Level", the hydrostatic pressure, e.g. with full

and empty vessel, is entered for adjustment. A superimposed pres-

sure is detected by the slave sensor and automatically compensated.

See the following example:

2

1

100%

0%

5

m

(196.

9")

4

3

Fig. 22: Parameter adjustment example "Min./max. adjustment, level measure-

ment"

1 Min. level = 0 % corresponds to 0.0 mbar

2 Max. level = 100 % corresponds to 490.5 mbar

3 VEGABAR 81

4 VEGABAR 81 - Slave sensor

If these values are not known, an adjustment with levels of for exam-

ple 10 % and 90 % is also possible. By means of these settings, the

real filling height is then calculated.

The real product level during this adjustment is not important, be-

cause the min./max. adjustment is always carried out without chang-

ing the product level. These settings can be made ahead of time

without the instrument having to be installed.

Setup - Adjustment