4 recurring test and function test – VEGA VEGASWING 66 - two-wire User Manual

Page 24

24

6 Setup

VEGASWING 66 • - two-wire

43758-EN-130322

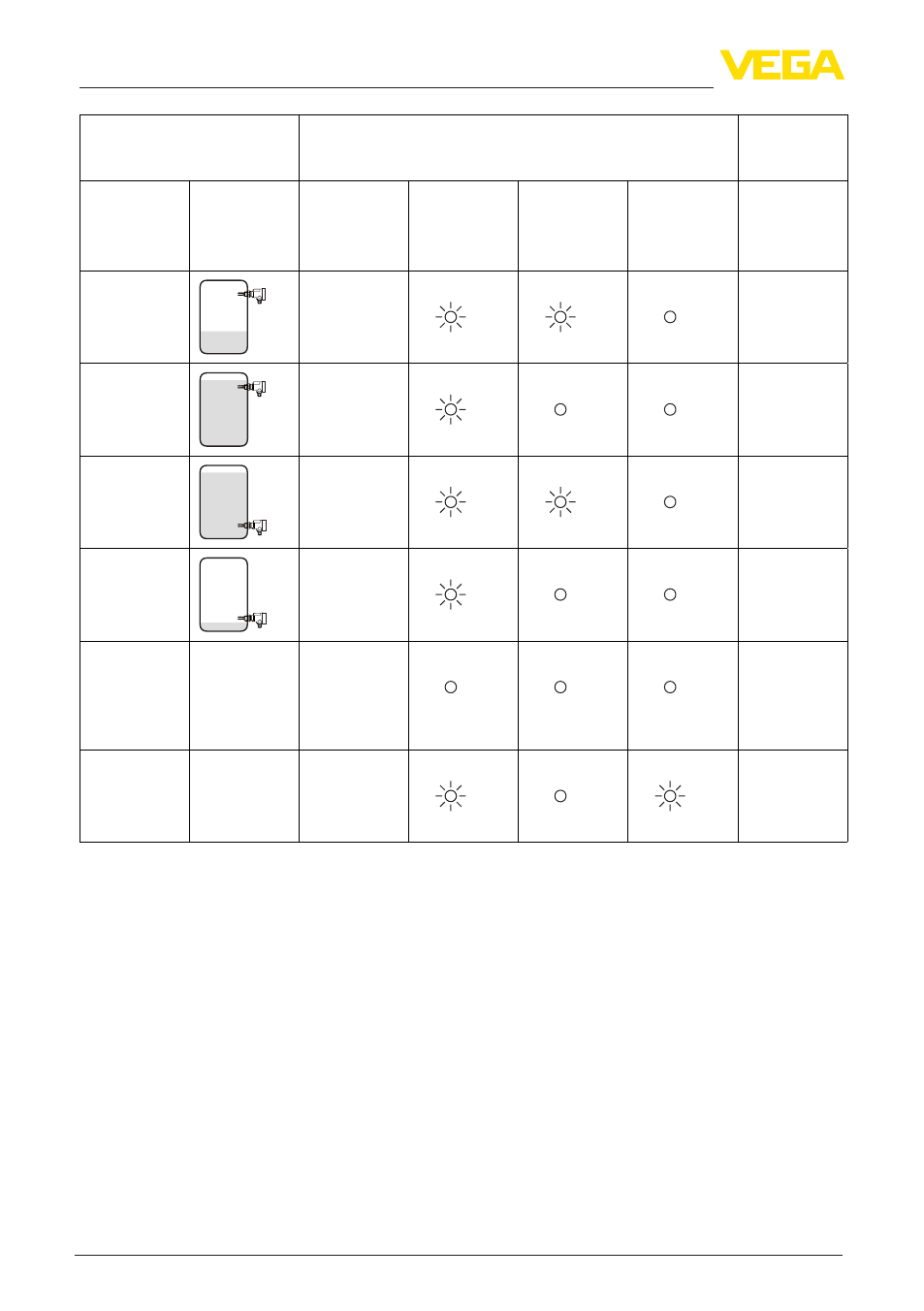

Sensor

Signal con-

ditioning

instrument

Mode on the

signal con-

ditioning

instrument

Level

Signal cur-

rent - Sensor

Signal lamp -

green

Voltage sup-

ply

Signal lamp -

yellow

Switching

status

Signal lamp

- red

Fault mes-

sage

Analogue

- input con-

trol

1)

Mode max.

Overflow pro-

tection

approx. 8 mA

> 3.8 mA

< 11.5 mA

Mode max.

Overflow pro-

tection

approx. 16 mA

> 12.5 mA

< 21.6 mA

Mode min.

Dry run pro-

tection

approx. 8 mA

> 3.8 mA

< 11.5 mA

Mode min.

Dry run pro-

tection

approx. 16 mA

> 12.5 mA

< 21.6 mA

Failure of the

supply volt-

age

Mode (max./

min.)

any

-

≤ 3.6 mA

≥ 21 mA

Fault message

Mode (max./

min.)

any

approx.

1.8 mA

≤ 3.6 mA

≥ 21 mA

6.4 Recurring test and function test

There are the following possibilities to carry out the recurring function

test:

1. Filling of the vessel up to the switching point

2. Dismounting of the sensor and immersion in the the original prod-

uct

3. Short interruption of the supply line to the sensor

4. Pushing the test key on the signal conditioning instrument

1 Filling the vessel up to the switching point

If this does not cause any problems, you can fill the vessel up to the

switching point and monitor the correct sensor reaction.

Implementation - Func-

tion test

1)

Electronics directly evaluated via the analogue input of a control system

(without signal conditioning instrument)