4 mounting, 1 general instructions – VEGA VEGASWING 66 - two-wire User Manual

Page 11

11

4 Mounting

VEGASWING 66 • - two-wire

43758-EN-130322

4 Mounting

4.1 General instructions

Make sure that all parts of the instrument coming in direct contact

with the process, especially the sensor element, process seal and

process fitting, are suitable for the existing process conditions, such

as process pressure, process temperature as well as the chemical

properties of the medium.

You can find the specifications in chapter "Technical data" and on the

nameplate.

In general, VEGASWING 66 can be installed in any position. The

instrument only has to be mounted in such a way that the tuning fork

is at the height of the desired switching point.

The tuning fork has lateral markings (notches) that indicate the

switching point with vertical mounting. The switching point refers

to water with the basic setting of the sensitivity switch ≥ 0.7 g/cm³

(0.025 lbs/in³). When mounting VEGASWING 66, make sure that

this marking is at the height of the requested switching point. Keep in

mind that the switching point of the instrument is shifted if the medium

has a density other than water - water 1 g/cm³ (0.036 lbs/in³). For

products < 0.7 g/cm³ (0.025 lbs/in³) and > 0.47 g/cm³ (0.018 lbs/in³)

the density switch must be set to ≥ 0.5 g/cm³.

Keep in mind that foams with a density > 0.45 g/cm³ (0.016 lbs/in³)

are detected by the sensor. This can cause faulty switchings particu-

lary when used as dry run protection system.

2

3

1

4

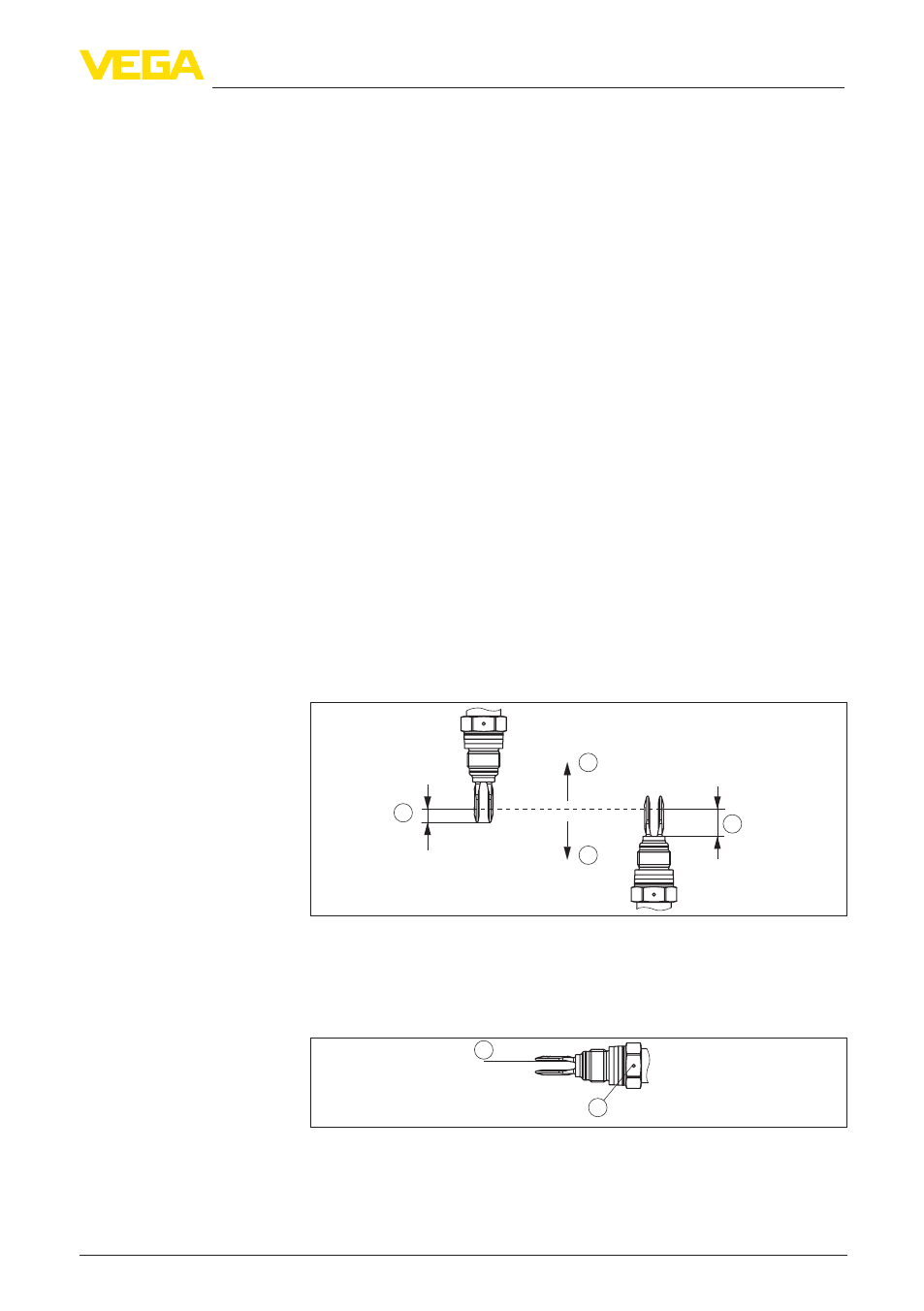

Fig. 3: Mounting vertical

1 Switching point approx. 13 mm (0.51 in)

2 Switching point with lower density

3 Switching point with higher density

4 Switching point approx. 33 mm (1.3 in)

1

2

Fig. 4: Mounting horizontal

1 Switching point

2 Marking with screwed version on top, with flange versions directed to the

flange holes

Suitability for the process

conditions

Switching point