VEGA VEGAPULS 62 (≥ 2.0.0 - ≥ 4.0.0) Foundation Fieldbus User Manual

Page 23

23

4 Mounting

VEGAPULS 62 • Foundation Fieldbus

36506-EN-121011

Constructional requirements on the surge pipe:

•

Material metal, smoother inner tube

•

Preferably pultruded or straight beaded stainless steel tube

•

Welded joint should be straight and lie in one axis with the holes

•

Flanges are welded to the tube according to the orientation of the

polarisation level

•

In case of a extension with a welding neck flange or pipe collar

as well as when a ball valve is used, the inner surfaces should be

aligned and accurately joined together

•

Gap size with junctions ≤ 0.1 mm

•

Do not weld through the pipe wall. The surge pipe must remain

smooth inside. Roughness and beads on the inside caused by

unintentional penetration should be removed since they cause

strong false echoes and encourage buildup

•

Surge pipes must extend all the way down to the requested min.

level, as measurement is only possible within the tube

•

Diameter of holes ≤ 5 mm, any number OK, on one side or com-

pletely through

•

The antenna diameter of the sensor should correspond to the

inner diameter of the tube

•

Diameter should be constant over the complete length

An alternative to measurement in a surge pipe is measurement in a

bypass tube outside of the vessel.

0 %

100 %

1

2

5

4

3

6

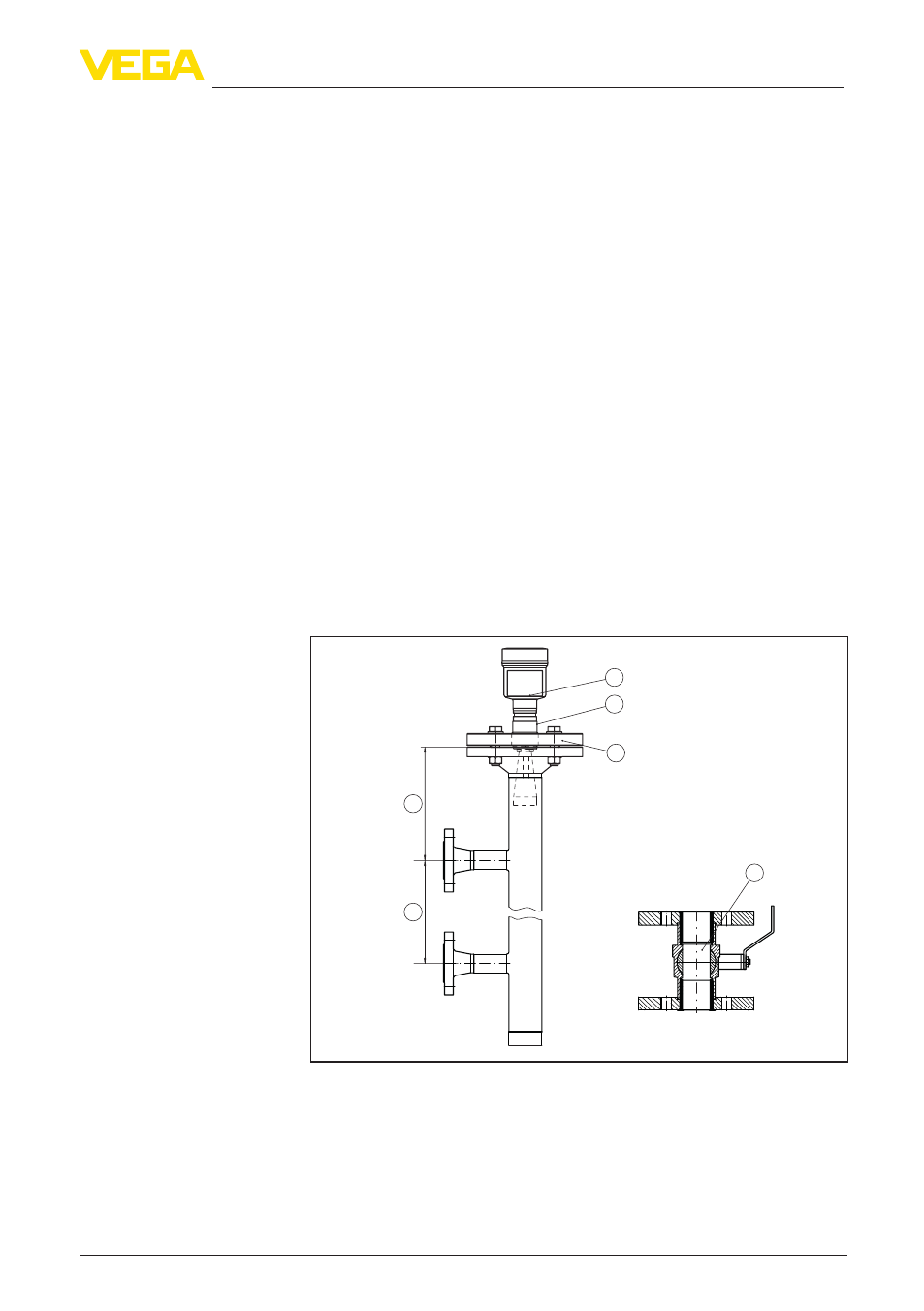

Fig. 20: Configuration bypass

1 Radar sensor

2 Marking of the polarisation plane

3 Instrument flange

4 Distance sensor reference plane to upper tube connection

5 Distance of the tube connections

6 Ball valve with complete opening

Measurement in the

bypass